Welding of an element of a track unit and a rail section without adding any material

A component and track section technology, which is applied in the field of welding between track unit components and rail profile steel without any added materials, can solve the problems of increasing the cost of the connection process and decreasing the hardness of the track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

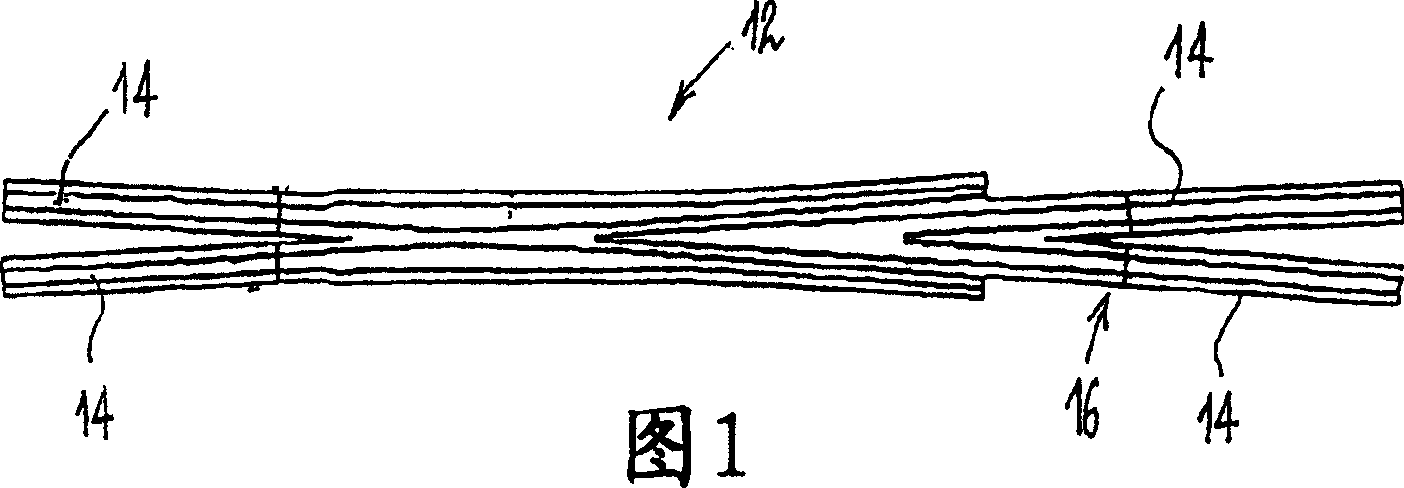

[0038] Figure 1 shows a crossing frog that allows two sections of intersecting track to cross. Therefore, the four ends of the cross frog 12 are connected to four running lines 14 .

[0039] Each line section 14 is connected to the frog by a metal-free weld 16 .

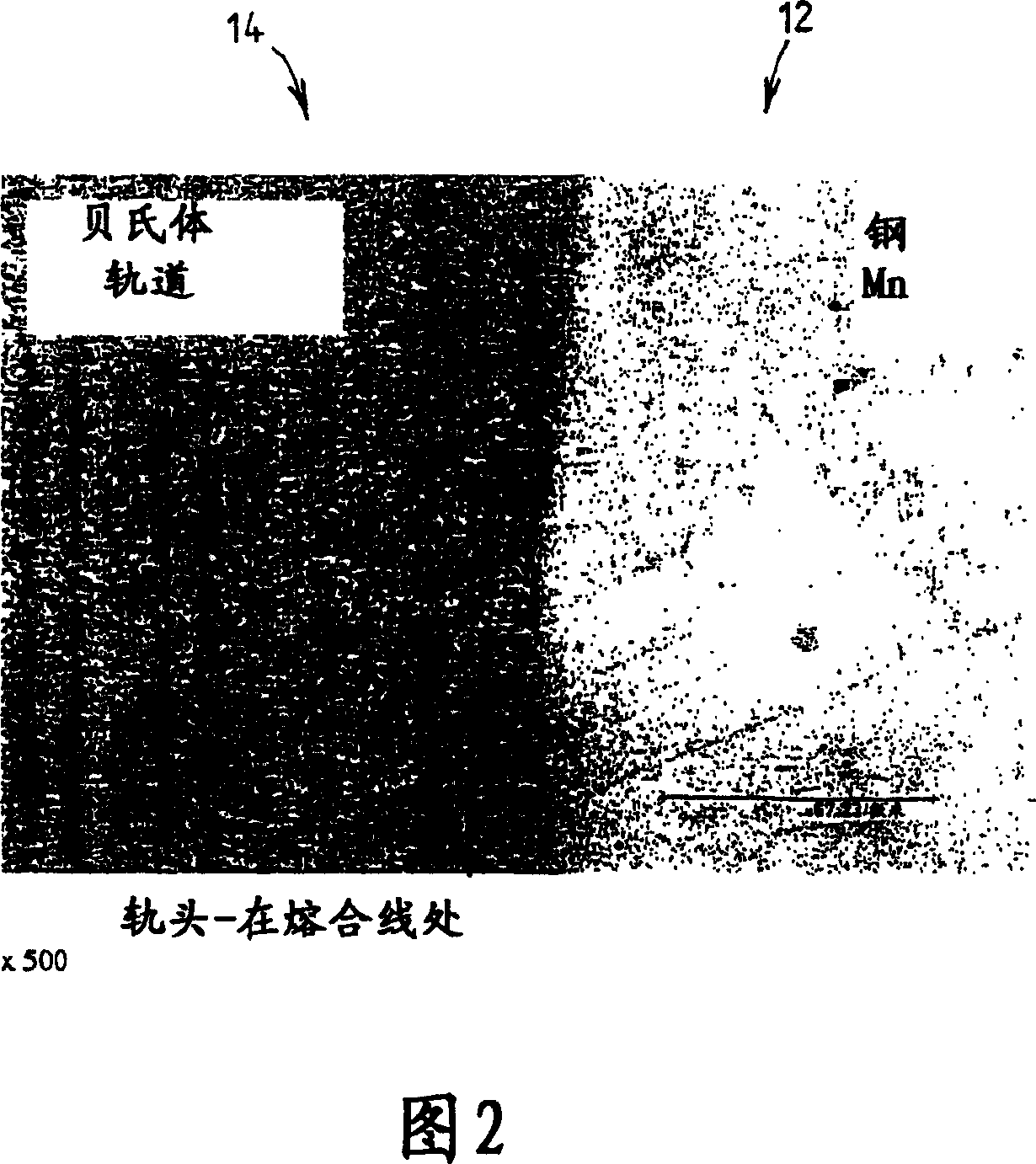

[0040] As known per se, the frog 12 is made of high-alloy steel, in particular steel with a content of at least 5% by weight of at least one alloying element.

[0041] The steel is in particular an alloyed steel containing 12-14% by weight of manganese, and the frogs are formed by moulding. This bell steel is a well known steel called HADFIELD.

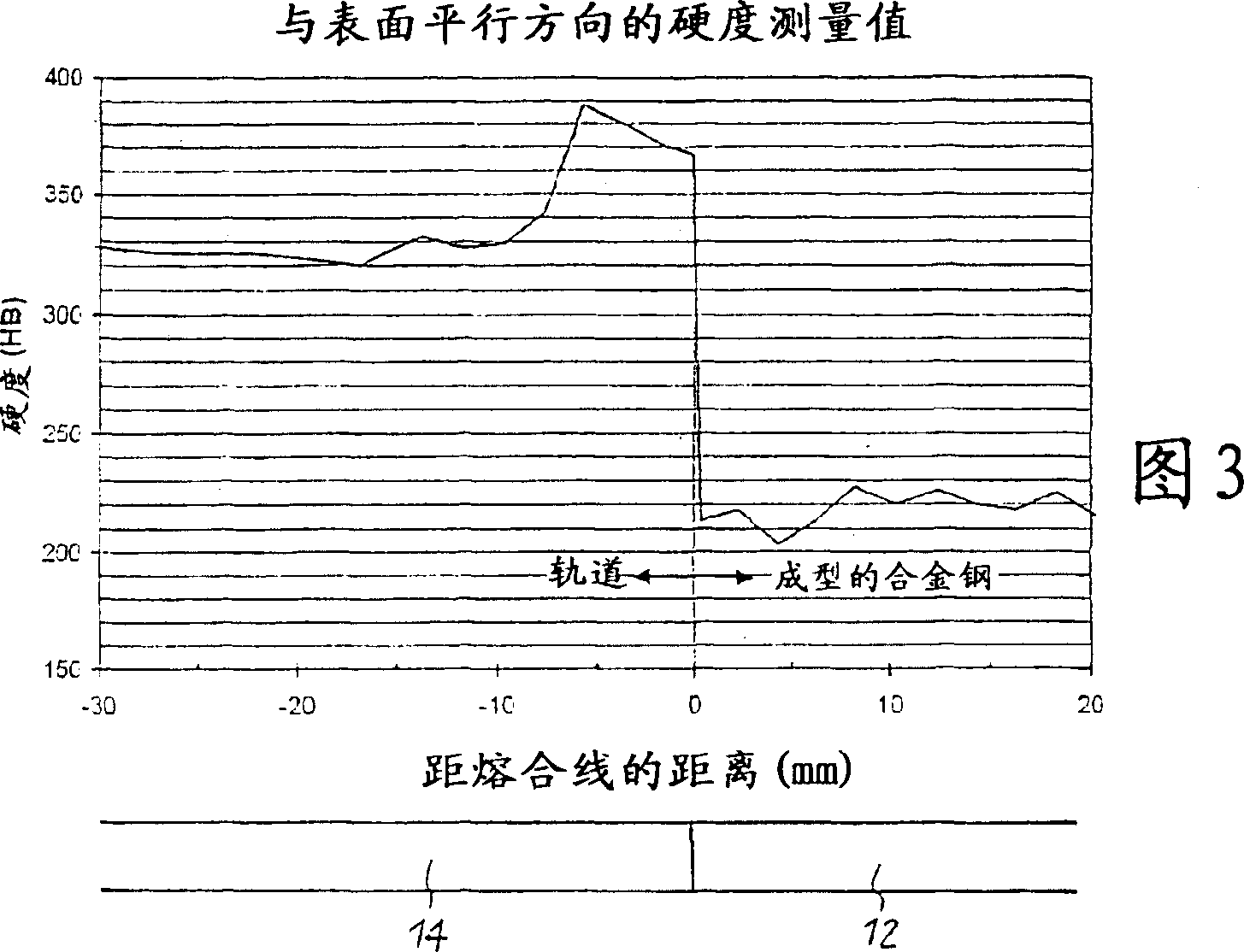

[0042] The hardness of this steel is 170-230HB.

[0043] In accordance with the present invention, the track sections 14 are made of medium alloy low carbon steel with a carbon content of less than 0.55 wt. Metallized welds. The carbon content of the medium alloy low carbon steel is preferably less than 0.5% by weight.

[0044] The medium alloy low carbon steel is pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com