(Meth)acrylate resin composition having excellent impact resistance and transparency

一种丙烯酸酯类、树脂组合物的技术,应用在丙烯酸酯类树脂组合物领域,能够解决丙烯酸酯类树脂天然性能变差、冲击强度低等问题,达到改善透明度、优异硬度和耐冲击性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 7 and comparative example 1 to 5

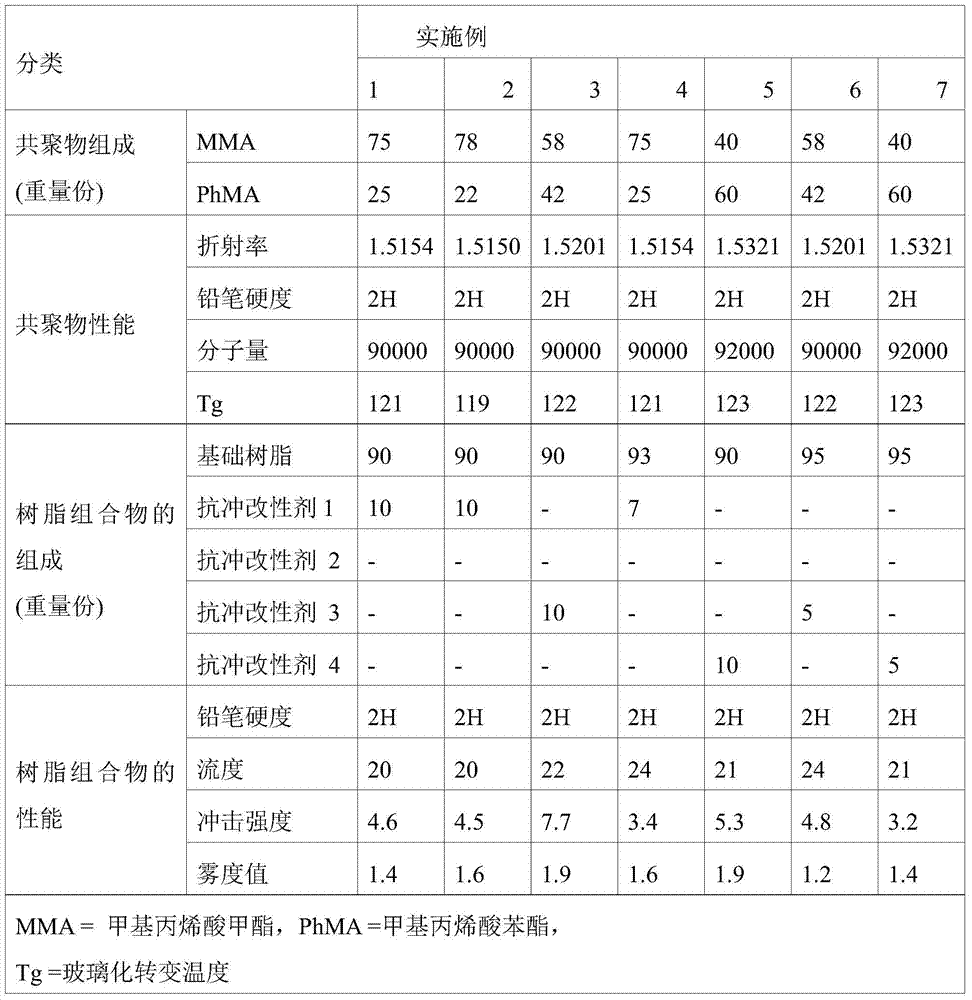

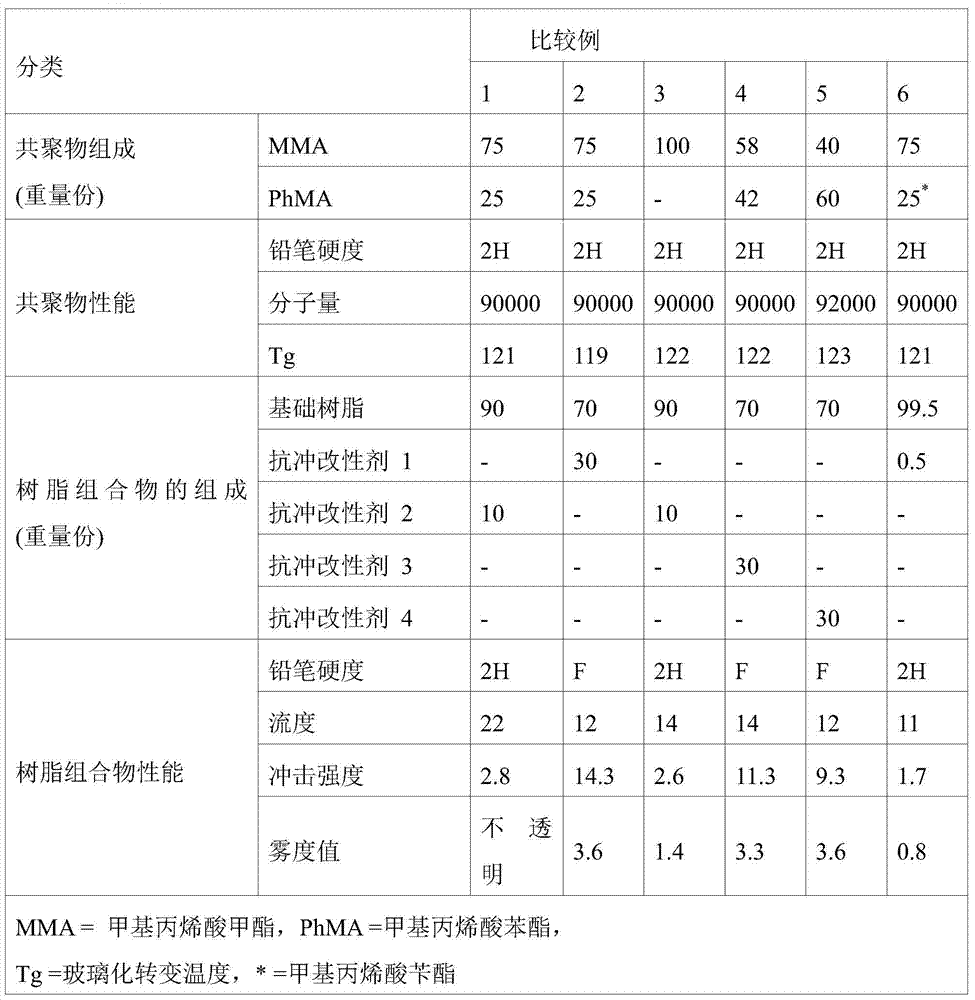

[0032] As a base resin, poly(methyl methacrylate-phenyl methacrylate) copolymers according to the compositions summarized in Table 1 (Example) and Table 2 (Comparative Example) below were prepared. Properties (pencil hardness, molecular weight (weight average molecular weight) and glass transition temperature) of the prepared poly(methyl methacrylate-phenyl methacrylate) copolymer were measured. Next, impact modifiers were mixed according to the compositions summarized in Tables 1 and 2 below, and samples of the resin compositions were prepared by injection molding. The properties (pencil hardness, fluidity, impact strength and transparency (haze value)) of the prepared samples were measured. The results are summarized in Tables 1 and 2.

[0033] Impact modifier 1 in Tables 1 and 2 below is an ABS-based graft copolymer as a core-shell type (butadiene rubber exists as a core) butadiene-based polymer, which is obtained by emulsion polymerization according to the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com