Developing apparatus with developer transporting screw

A developing device and developer technology, which are applied in the direction of electric recording process applying charge pattern, equipment for applying electric recording process of charge pattern, electric recording technique, etc. The problem of uneven distribution of agent developer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

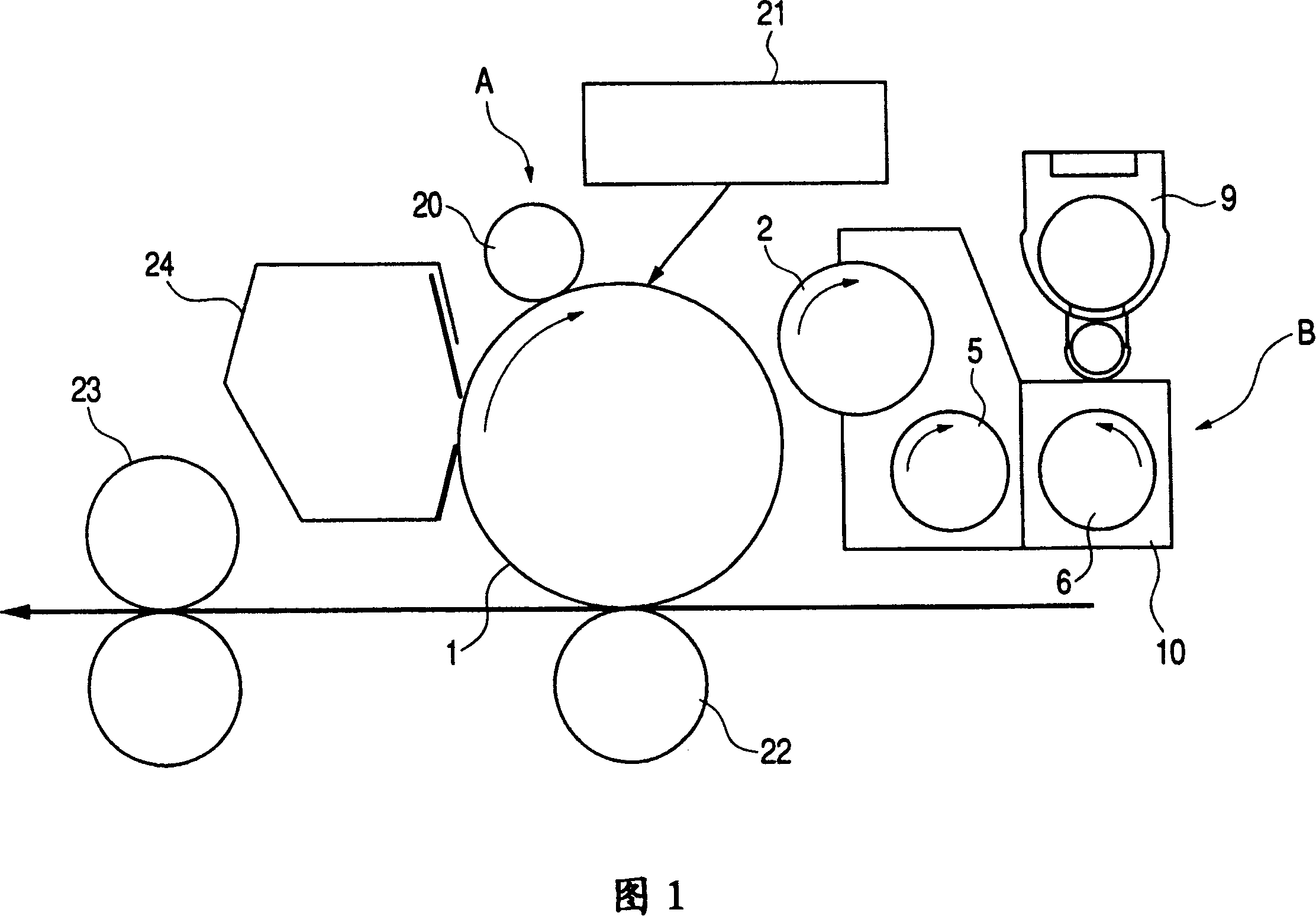

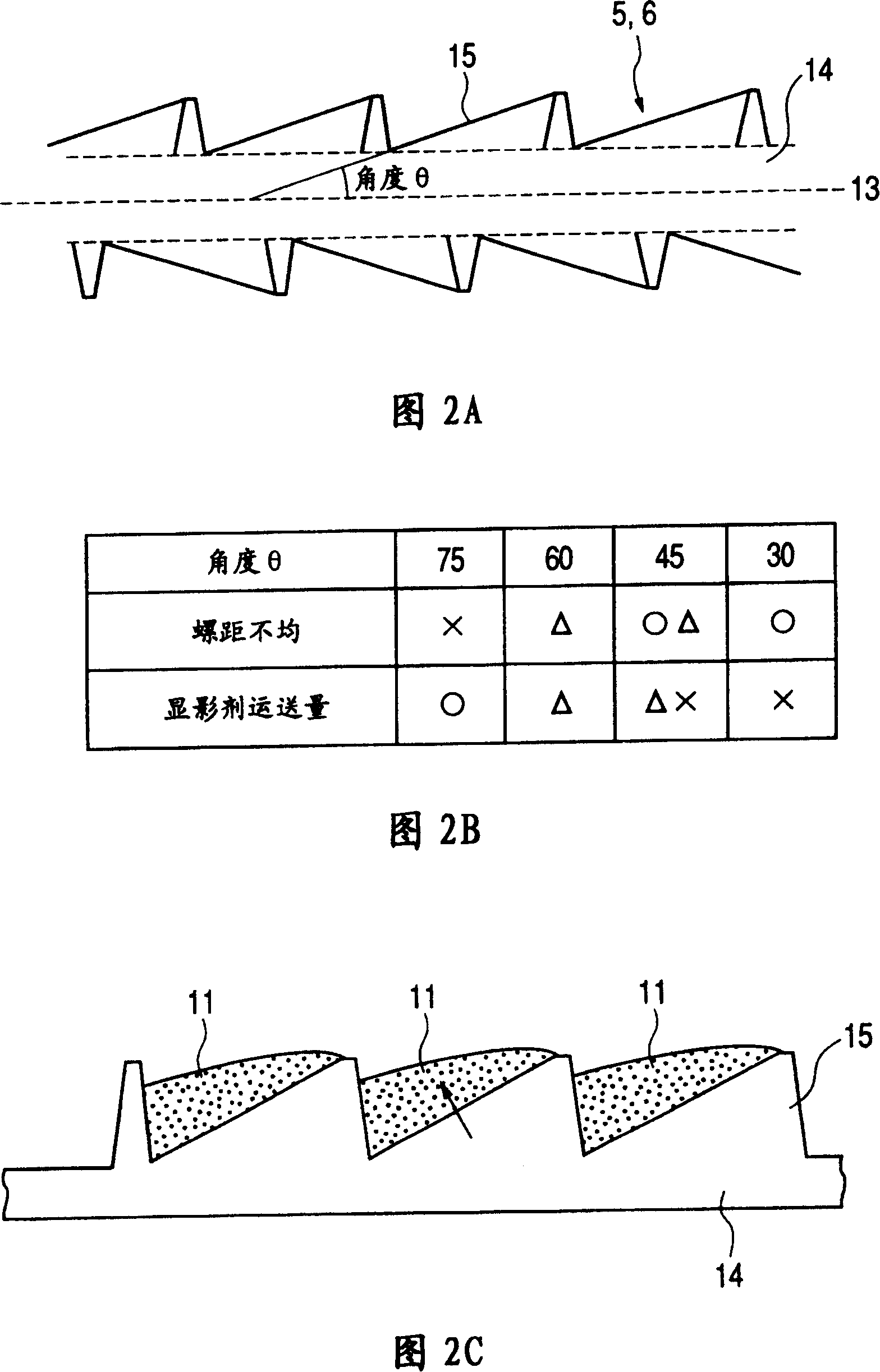

[0041] Next, an image forming apparatus equipped with the developing apparatus of the first embodiment of the present invention will be described with reference to FIG. 1 and FIGS. 2A , 2B and 2C. 1 is a schematic cross-sectional view of the entire image forming apparatus, FIGS. 2A, 2B and 2C show a screw for conveying the developer, FIG. 2A is a view cut through a plane passing through the rotation center line of the screw, and FIG. In the table of the results of the developer conveyance test, FIG. 2C is an explanatory diagram of the state of the developer conveyed by the screw.

[0042] Overall Configuration of Imaging Device

[0043]First, the overall configuration of the imaging device 2A will be roughly described with reference to FIG. 1 . In FIG. 1, 1 is a rotatable photoreceptor drum of a developing carrier, and an electrifying device 20, an exposing device 21, a developing device B, and a transfer device 22 are arranged in this order in the rotation direction of the p...

no. 2 Embodiment approach

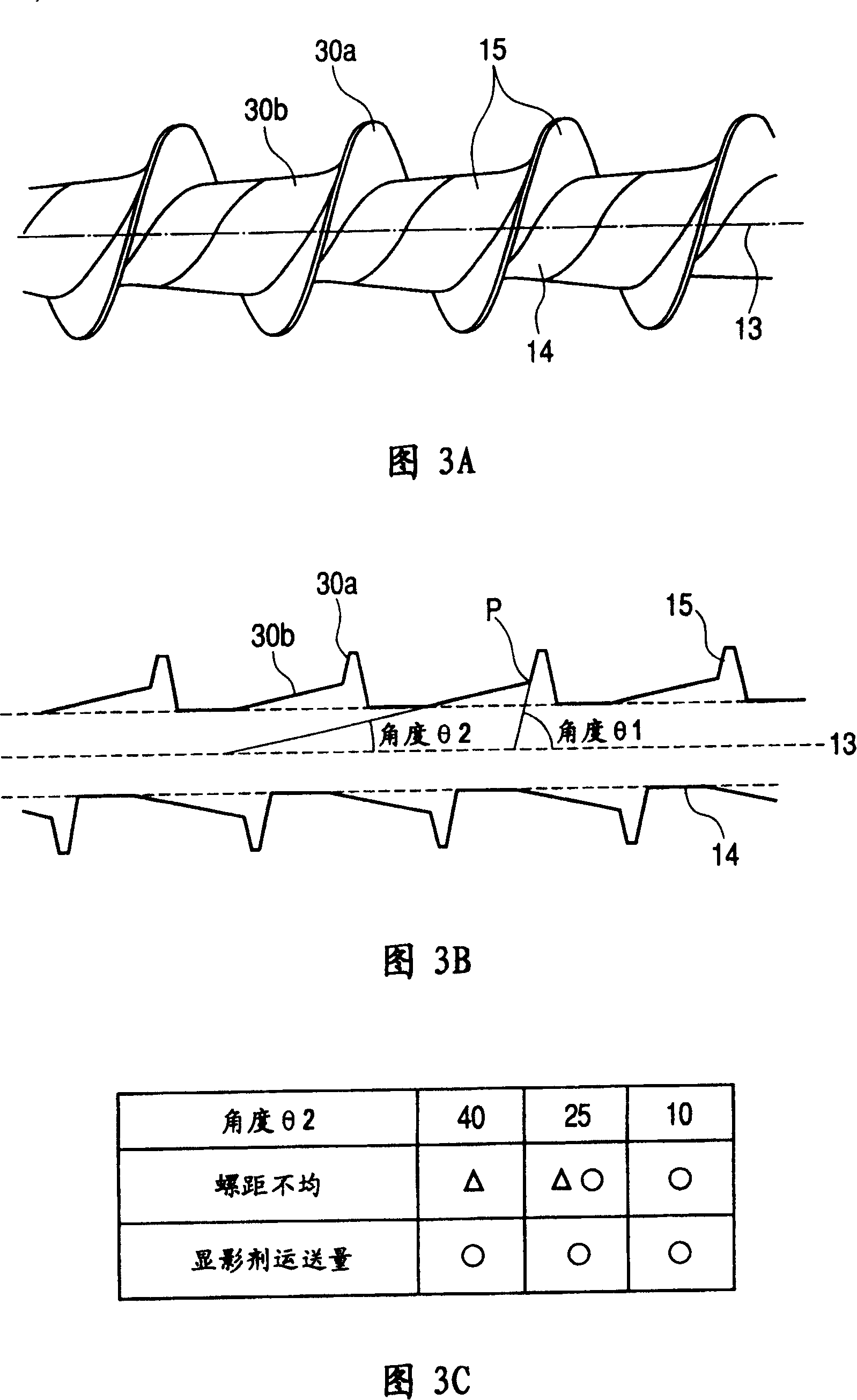

[0058] In contrast to the above-mentioned first embodiment, the conveying surface of the blade of the screw facing the developer conveying direction is constituted by a single plane. Multiple transport surfaces with different inclination angles". The description will be made with reference to FIGS. 3A , 3B and 3C to FIGS. 5A and 5B .

[0059] 3A, 3B and 3C show the screw of the developing device according to the second embodiment, FIG. 3A is an external view of the screw, FIG. 3B is a cross-sectional view cut by a plane passing through the rotation center line of the screw, and FIG. Angle (tilt angle) Result table of developer conveyance test. 4A is an explanatory view of the state in which the developer is conveyed by the screw, and FIG. 4B is a diagram for explaining the distance (height) H1 from the surface (reference surface) of the rotating shaft of the screw to the tip of the blade and the intersection between the reference surface and the two surfaces 30a, 30b A cross...

no. 3 Embodiment approach

[0074] Next, the screw used in the developing device of the third embodiment will be described. 9 and 10 are cross-sectional views cut along a plane passing through the rotation center line of the screw according to the present embodiment, and are views for explaining the angle and the configuration length of the blades, respectively. The developer conveying direction is to the left in the figure.

[0075]The present embodiment is characterized in that a conveyance screw blade (first blade) 15 serving as a conveyance blade portion is helically wound around the shaft of the screw, and is arranged immediately after the conveyance screw blade 15 (developer conveyance blade). An addition screw blade (second blade) 16 as an addition blade portion is separately provided on the upstream side in the direction.

[0076] As shown in FIGS. 9 and 10 , let the angle formed by the conveying surface of the conveying screw blade 15 facing the developer conveying direction and the center line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com