Wax mould manufacturing method for golf club head

A golf club head and manufacturing method technology, which are applied to golf balls, golf clubs, casting and molding equipment, etc., can solve the problem that the club head cannot be suitable for mass production in the precision casting process, hinders the ejection of the mold core, and cannot successfully manufacture wax molds. and other problems, to achieve the effect of improving design margin and feasibility, increasing convenience, and increasing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical solutions, features and advantages of the present invention more clearly understood, specific embodiments of the present invention will be cited below, together with the accompanying drawings, as follows:

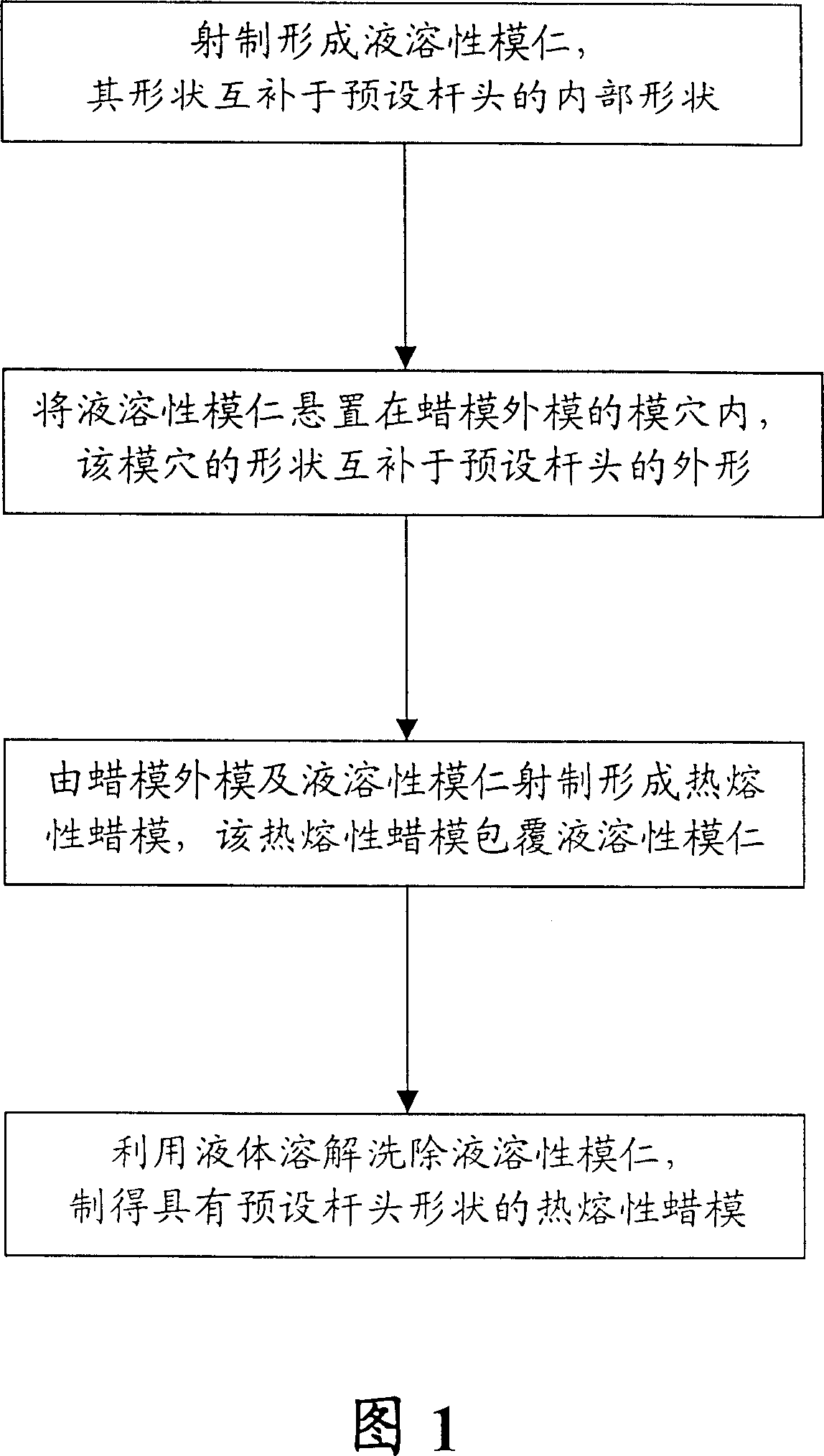

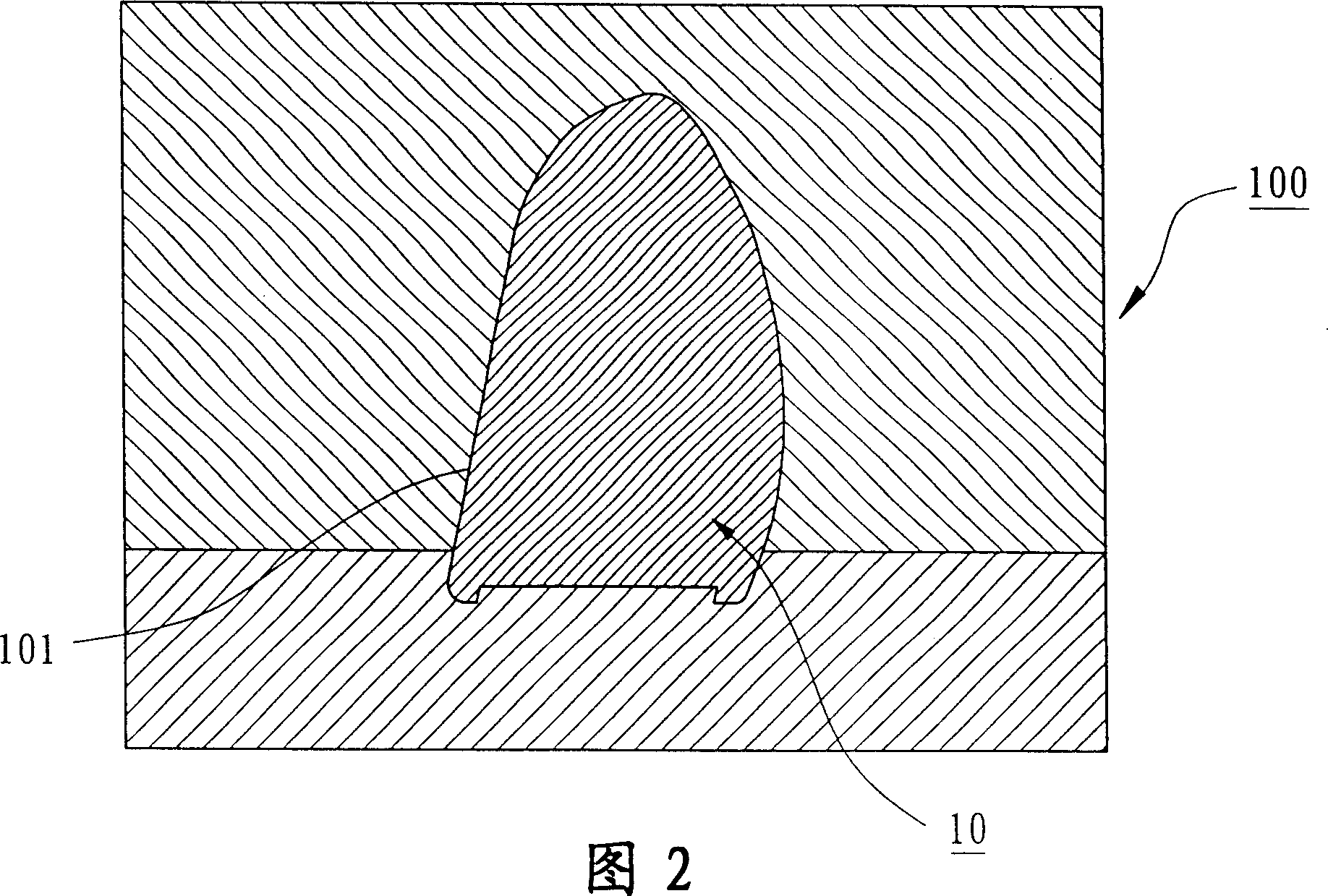

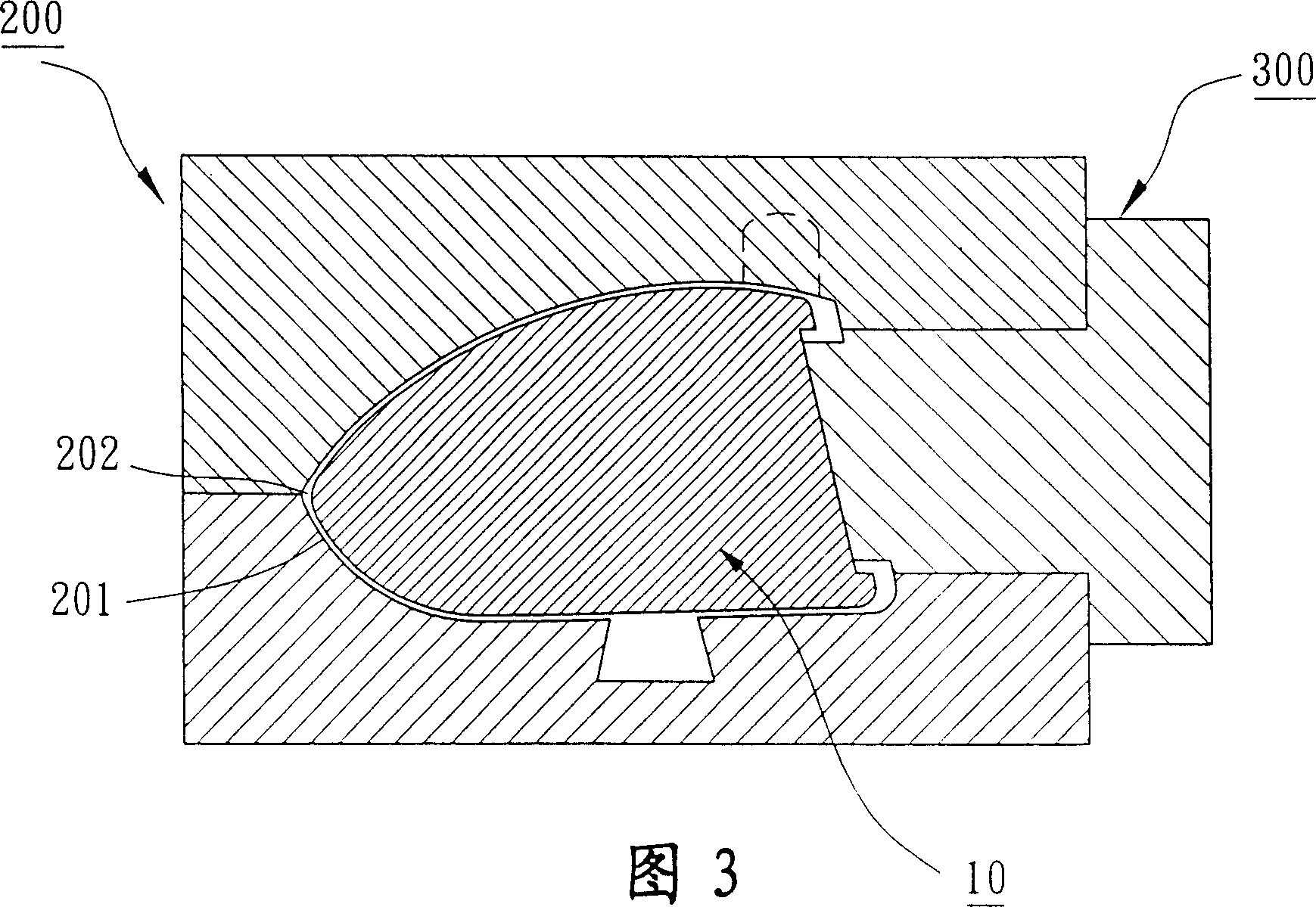

[0050] Please refer to Figures 1 and 2, the first step of the golf club head wax mold manufacturing method of the first embodiment of the present invention is to form a liquid-soluble mold core 10 by shooting a liquid-soluble base material, the liquid-soluble mold core The shape of 10 is complementary to the internal shape of the preset club head. Firstly, a mold core outer mold 100 is prefabricated, the mold core outer mold 100 is a combined mold, which can be combined to form a mold cavity 101, and the shape of the mold cavity 101 is equal to the internal shape of the predetermined rod head. During manufacture, the mold cavity 101 can be injected into a suitable liquid-soluble base material to form a liquid-soluble mold core 10 by inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com