Heat dissipation guide pipe

A technology of conduit and tube body, which is applied in the field of heat dissipation conduits, and can solve problems such as damage to heat dissipation conduits, deformation of heat dissipation conduits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

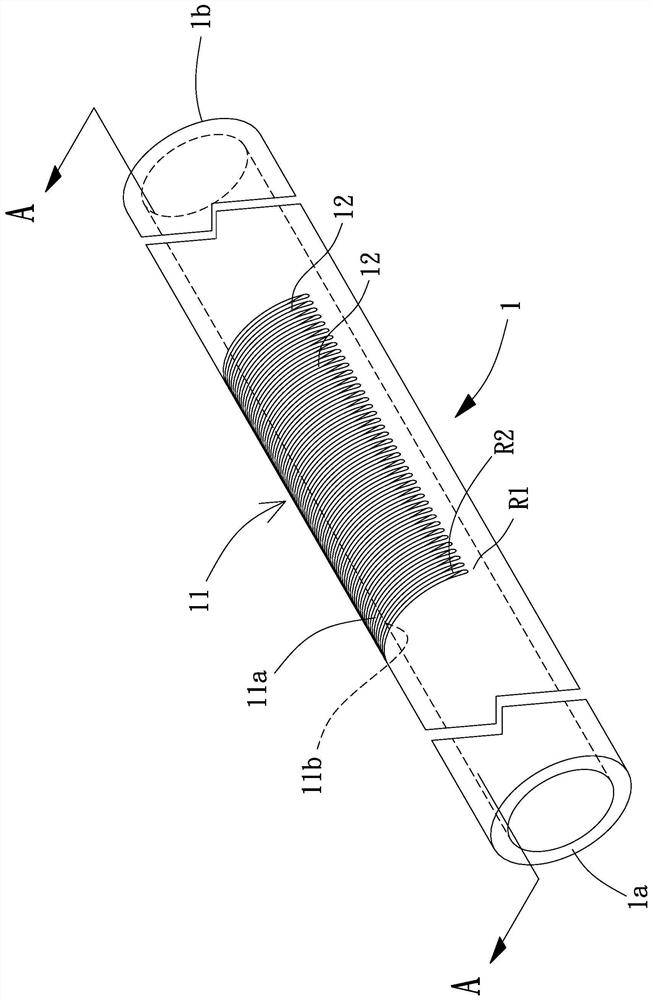

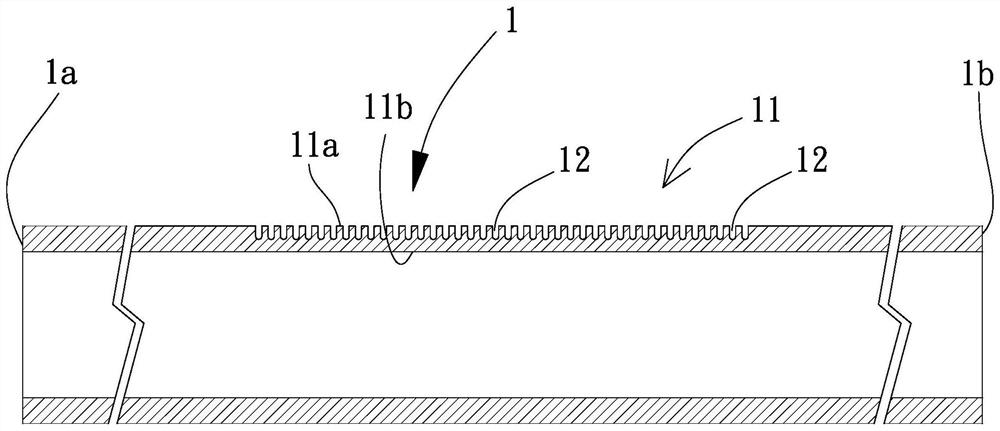

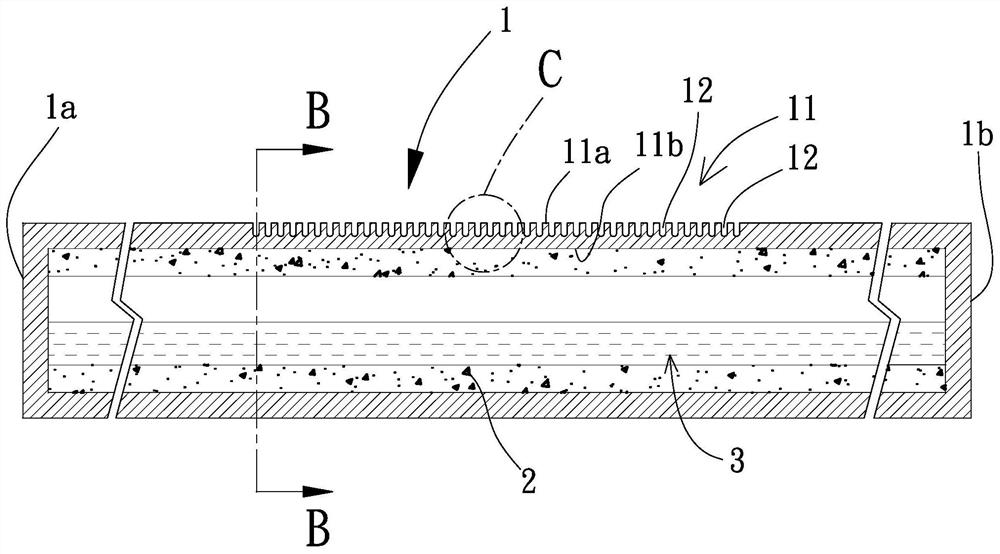

[0072] Please refer to figure 1 , Figure 2a As shown, it is the first embodiment of the heat dissipation duct of the present invention, wherein, figure 1 , Figure 2a In the unbent form of the heat dissipation conduit, the heat dissipation conduit includes a tube body 1 . Please refer to Figure 2b As shown, the heat dissipation pipe of the present invention can be applied to the heat pipe of the heat dissipation system or the pipe fitting of the water cooling system. When the heat dissipation pipe of the present invention is applied to the heat pipe of the heat dissipation system, the pipe body 1 can have a capillary structure 2 and a working fluid 3 inside. When the heat dissipation pipe of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com