Sealing device

A sealing device and metal casing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of low pressure test efficiency, high test cost, short service life of the sealing head, etc., to improve the pressure test efficiency, Provides service life and reduces test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

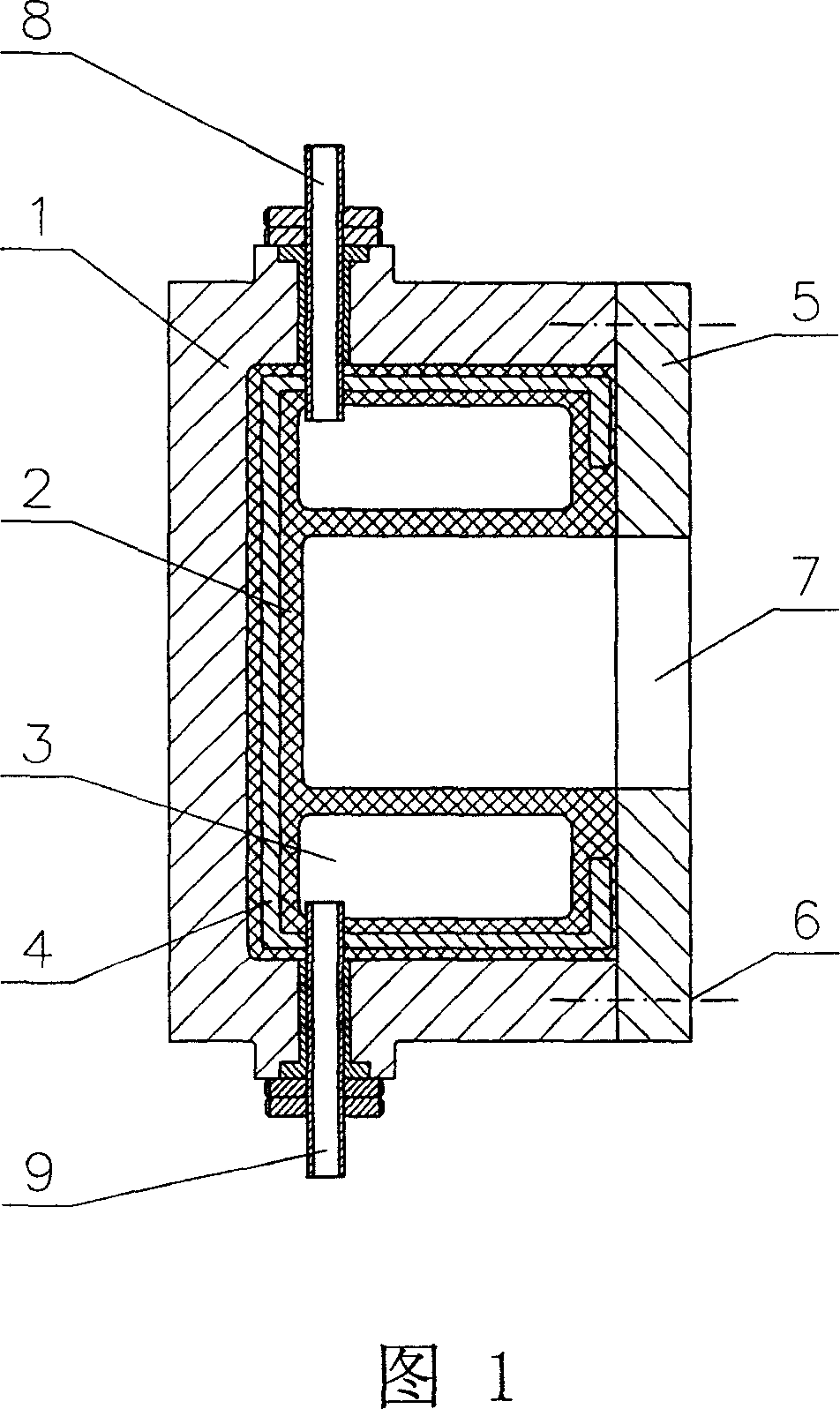

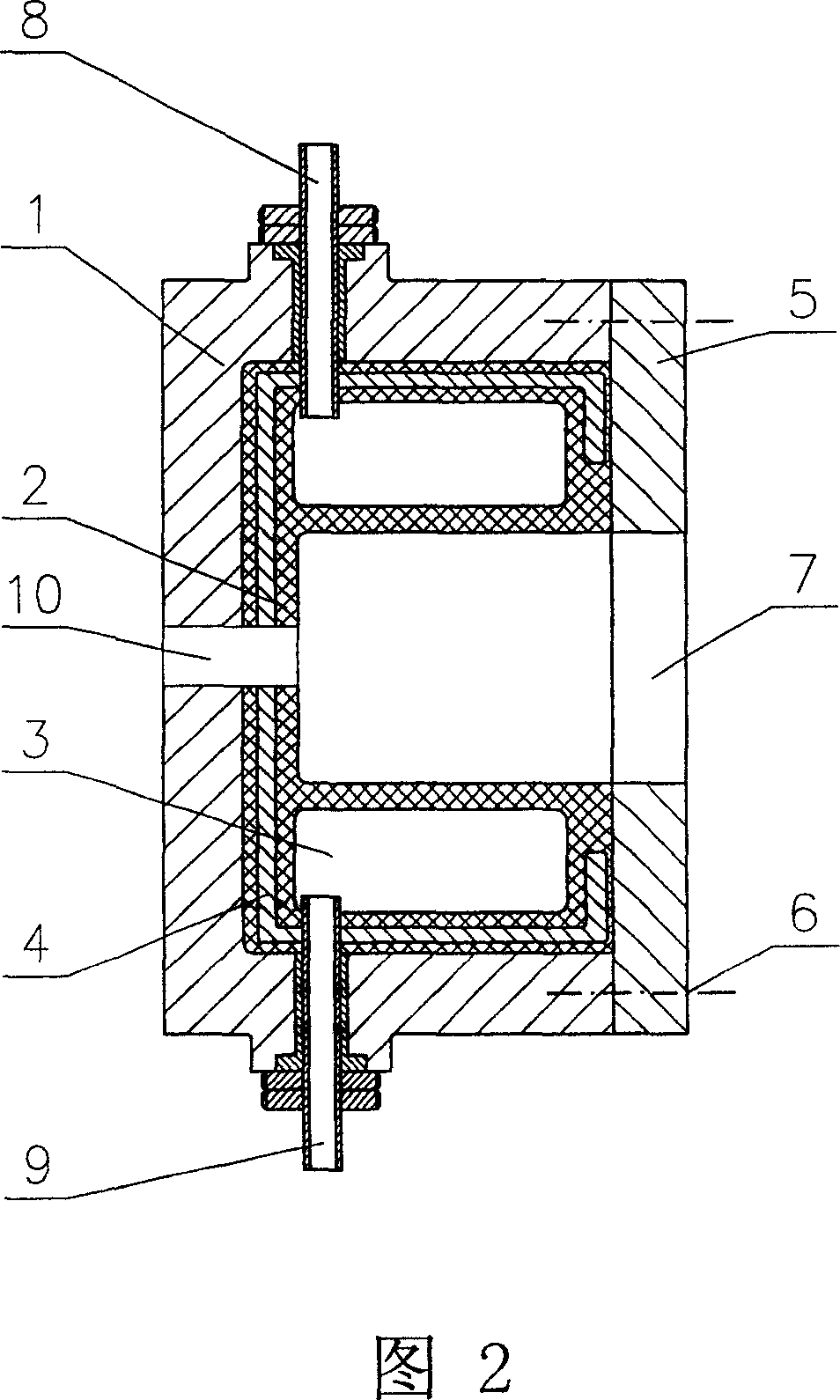

[0013] As shown in Figure 1, the present invention includes: a metal casing 1 with a "匚"-shaped radial section; a rubber layer 2 with a "匚"-shaped radial section arranged inside the casing 1, and a Ring-shaped rubber bag 3; a metal skeleton 4 with a "C"-shaped cross section is arranged in the rubber layer 2 outside the rubber bag 3. A guard plate 5 is connected to the inner end of the metal shell 2 through a fixing piece 6 to block the rubber bag 3 , and a through hole 7 corresponding to the diameter of the sealed part is provided in the center of the guard plate 6 . An oil inlet pipe 8 and an oil outlet pipe 9 are connected to the rubber bag 3 respectively, and are fixedly connected to the metal casing 1 .

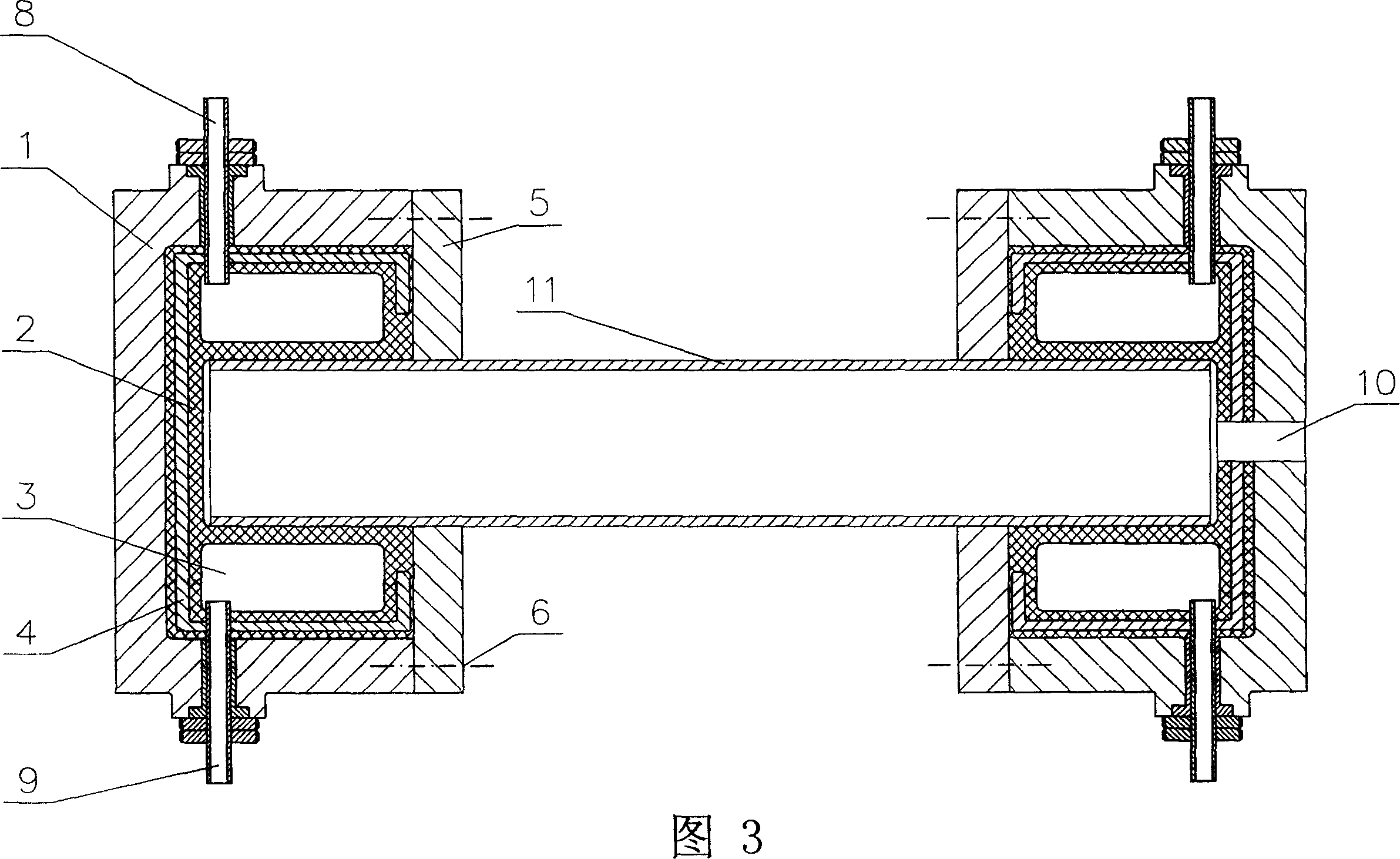

[0014] The above-mentioned embodiment is a sealing device arranged at one end that needs to be sealed. If both ends of the tool to be sealed adopt the present invention, and high-pressure water needs to be fed from one side, a communication device can be fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com