Scissors type lifting equipment

A lifting equipment, scissor-type technology, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of large force introduction and deviation, and achieve the effects of reducing control costs, avoiding transformation, and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

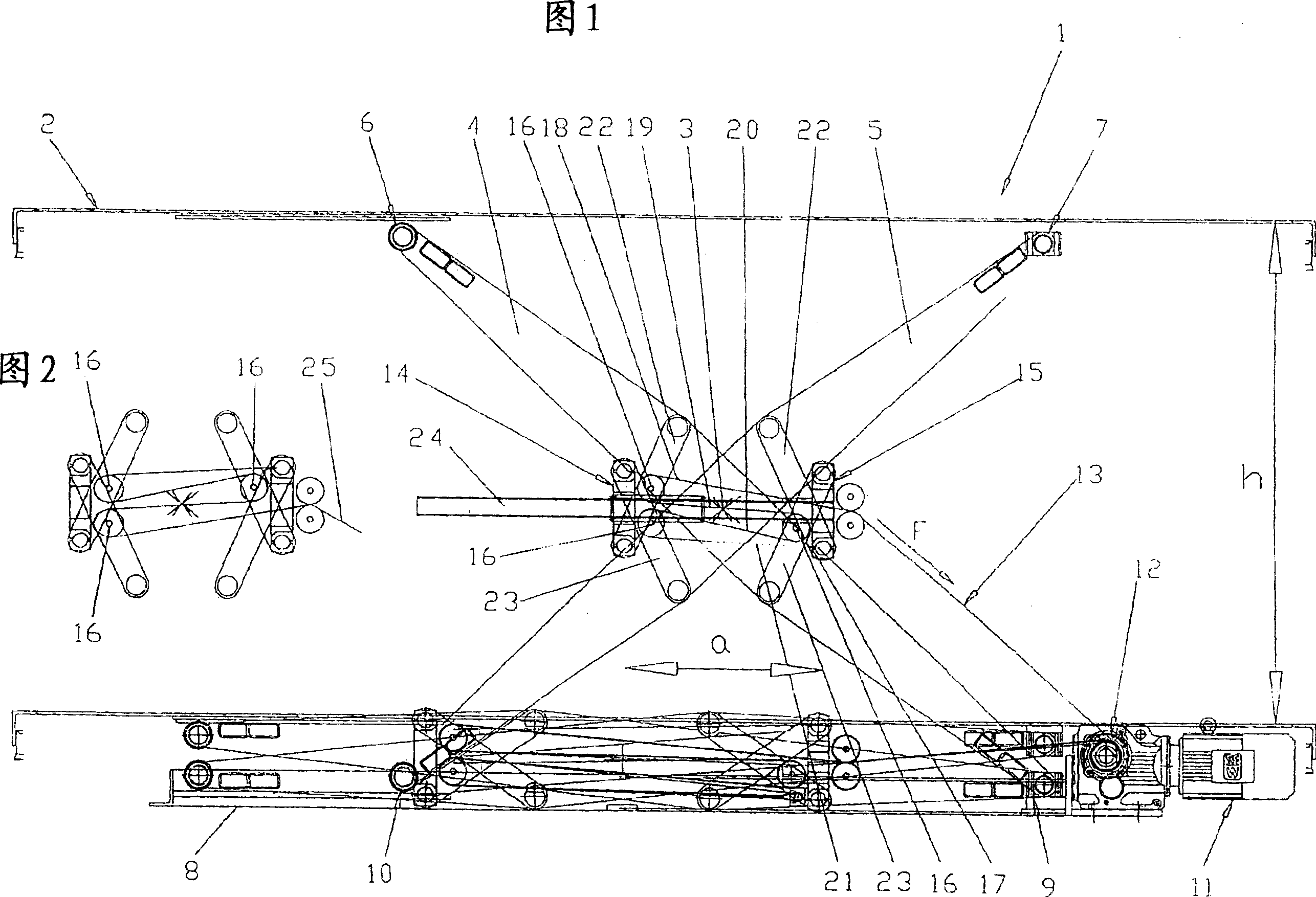

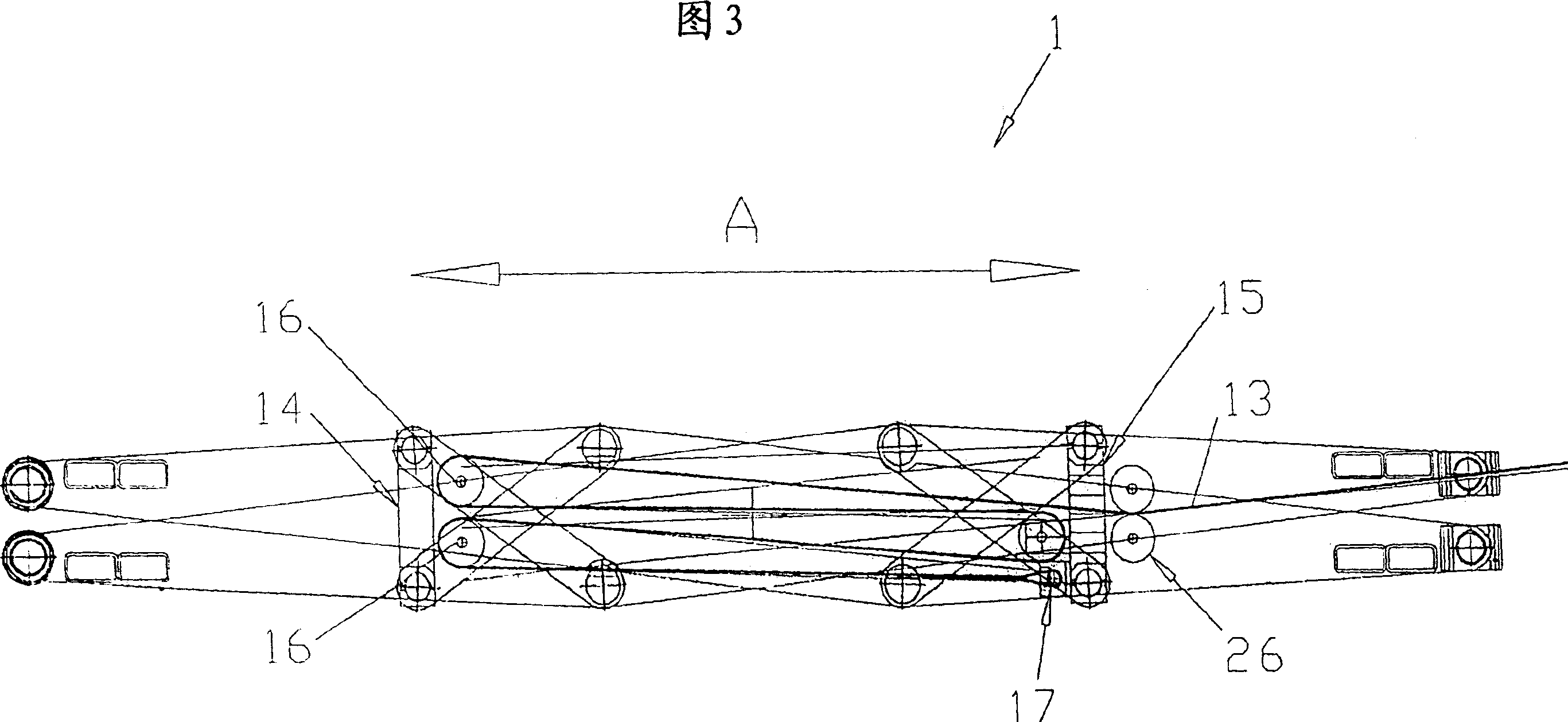

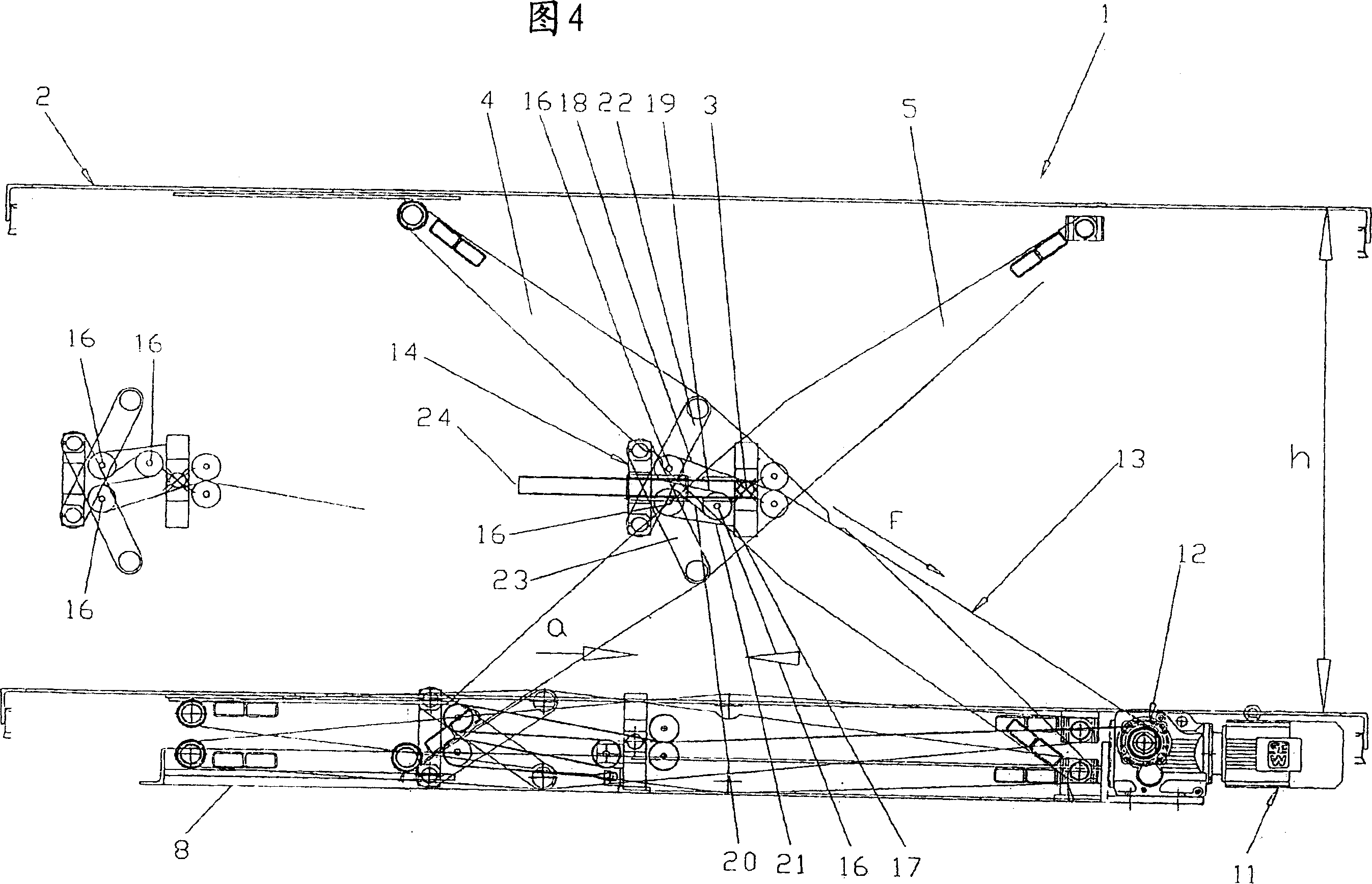

[0028]Fig. 1 shows a side view of the scissor lifting device 1 of the present invention. The scissor lifting device 1 has two scissor arms 4, 5 arranged under the lifting plane 2 and connected in pairs by a swing shaft 3, wherein the swing shaft 3 is set on the corresponding supporting lifting planes of the scissor arms 4, 5 The center between the ends 6, 7 of 2 and the ends 9, 10 supported on the bottom surface 8. The scissor lifting equipment 1 is equipped with a driving device 11 fixedly arranged on the bottom surface 8, and a traction tool 13 configured as a conveyor belt is provided on the reel 12 for raising and lowering the scissor arms 4 and 5. For this purpose, the scissor lifting equipment 1 is equipped with two parallel connection bridges 14, 15 arranged on both sides of the swing shaft 3, wherein the first connection bridge 14 is equipped with at least two steering rollers 16 and the second connection bridge 15 is equipped with A steering roller 16 and a fixing member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com