Device on carding machine

A technology of carding machine and carding drum, applied in the fields of deburring device, fiber processing, textile and papermaking, etc., can solve the problem of inability to influence, and achieve the effect of optimizing waste separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

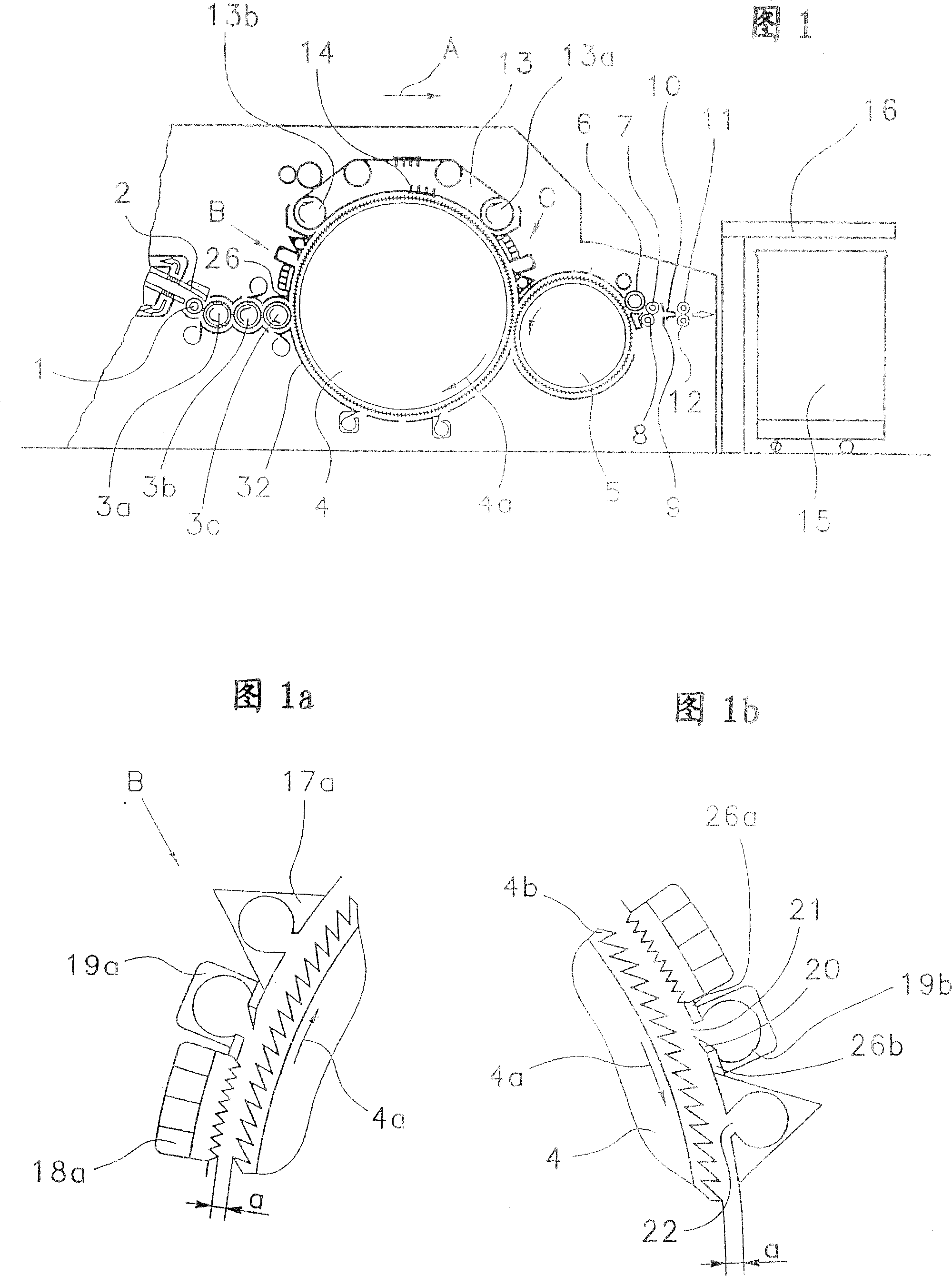

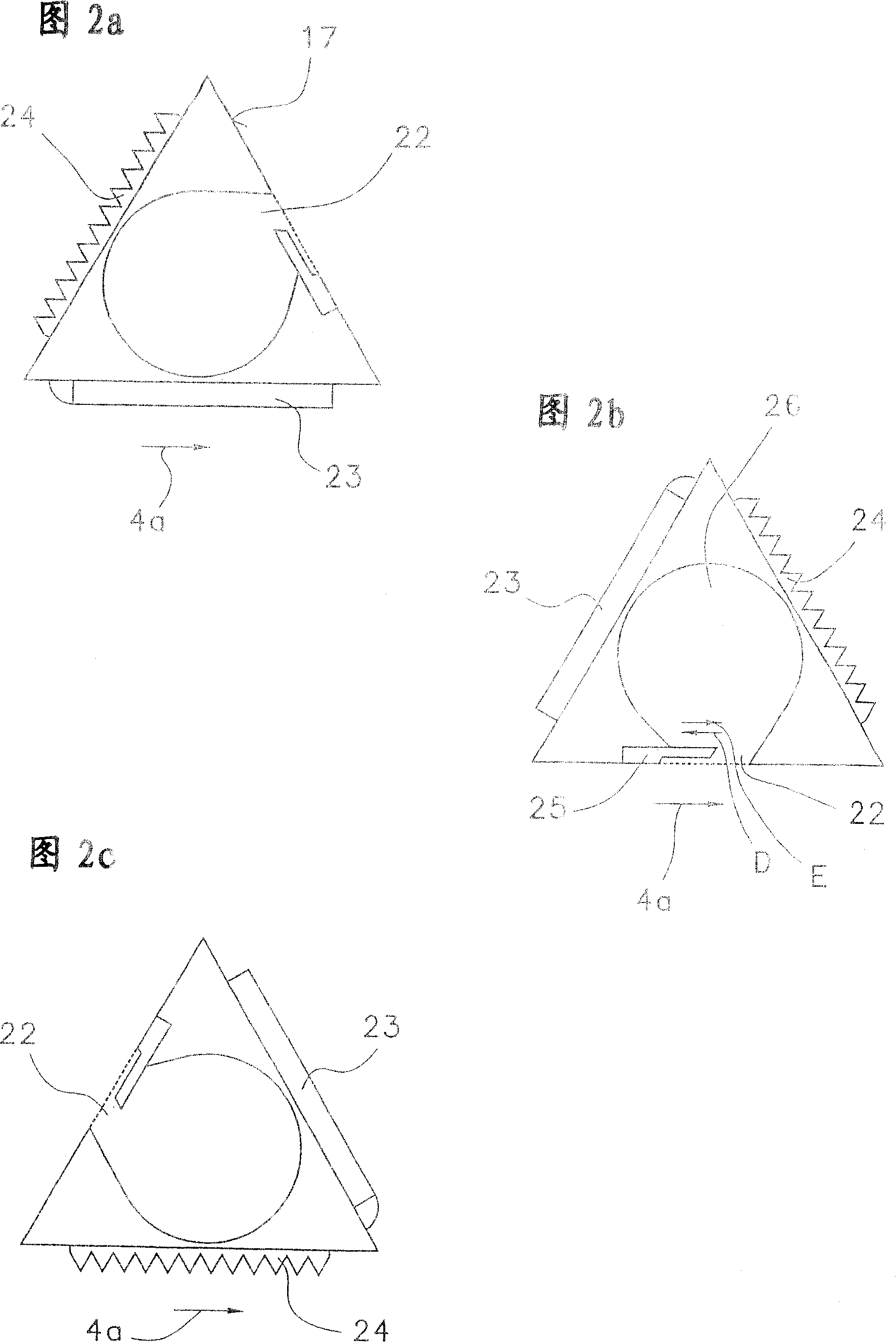

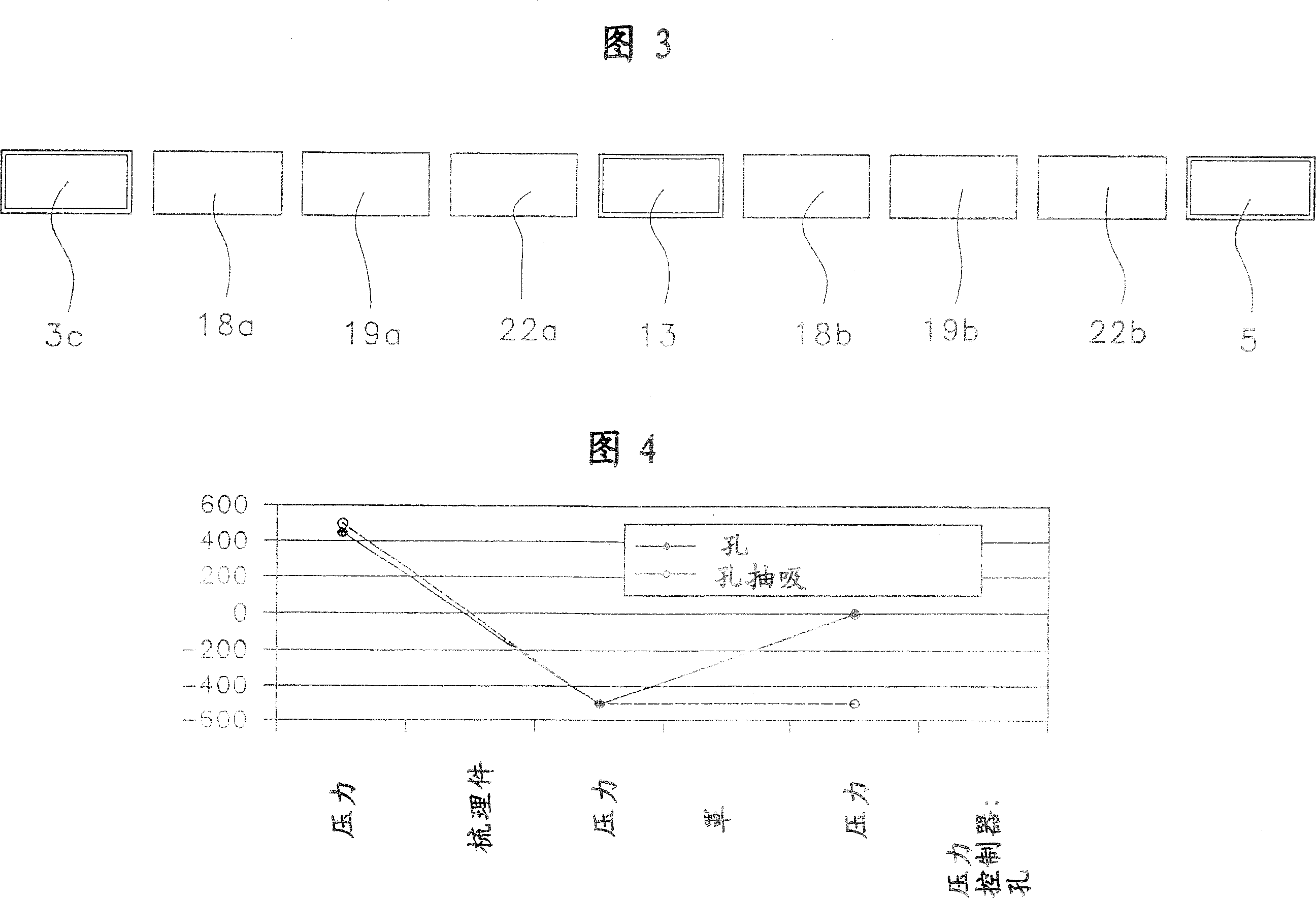

[0015] Fig. 1 shows a carding machine, such as Trützschler high-power carding machine DK903, including feeding roller 1, curtain type wool feeding table 2, licker-in rollers 3a, 3b, 3c, carding cylinder 4, doffer 5, stripping roller 6, press roller 7, 8, guide wool mesh 9, fiber web collection bell mouth 10, separating rollers 11, 12, revolving cover 13 with cover rod 14, can 15 and coiler 16. The direction of rotation of the rollers is indicated by a curved arrow. Use A to indicate the processing direction. The device 17 according to the invention can be installed, for example, at points B and / or C on the carding cylinder 4 . According to Fig. 1 a, in place B, look along the rotation direction 4a of carding cylinder 4, there are continuously the suction cover 19a of fixed carding member 18a, band separation blade 20 and separation hole 21, and what is called "pressure controller (Druckmanipulator)". "The member 17a with holes 22 according to the present invention. At point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com