Snap fit mechanism

A technology of engaging claws and fixing components, applied in the direction of fasteners, connecting components, mechanical equipment, etc., can solve the problems of release, inadvertent engagement, and disengagement of the engaging claws, so as to reduce the amount of elastic deformation and prevent inadvertent release. The effect of snapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described below.

[0016] [Embodiment 1]

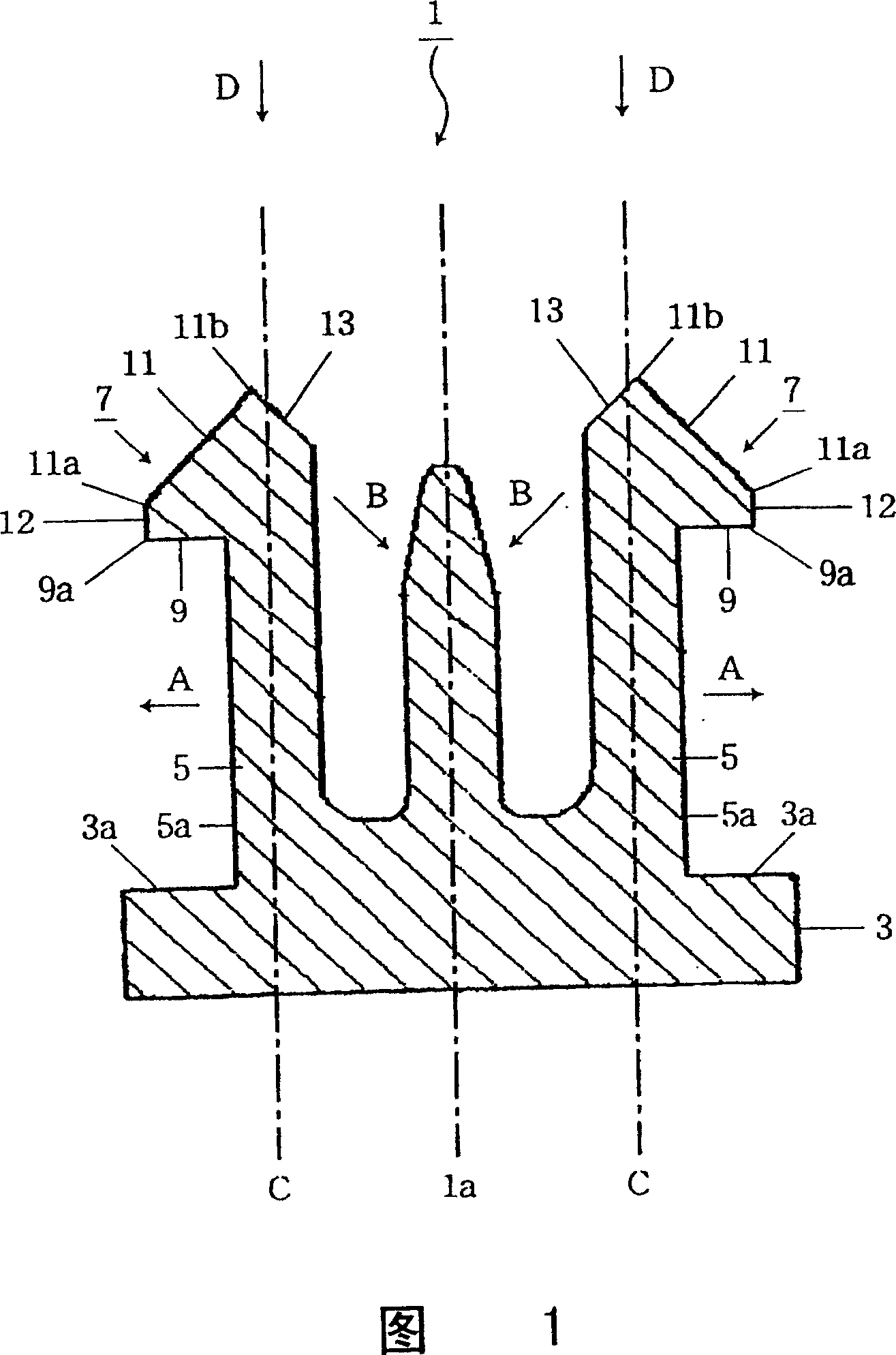

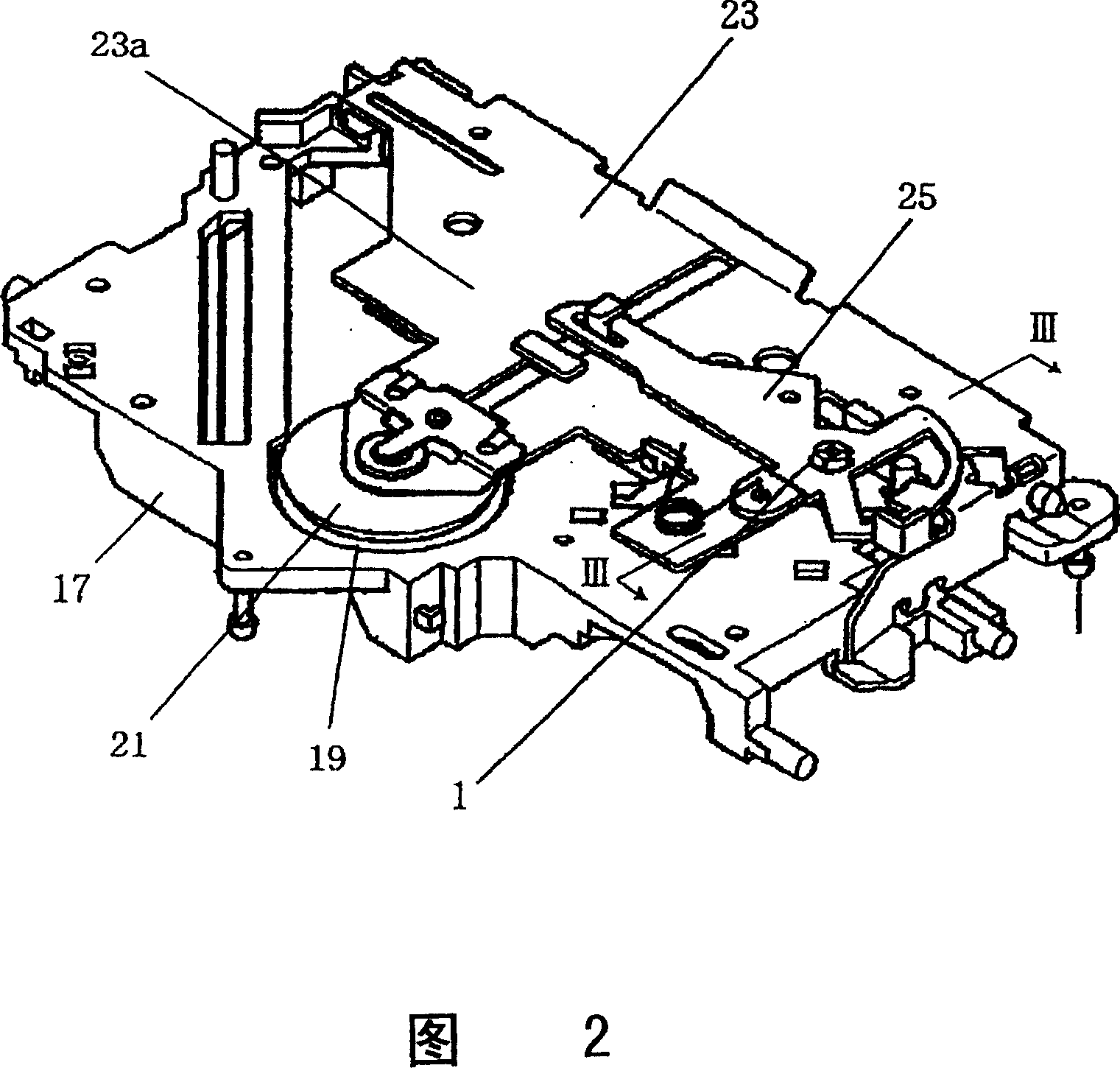

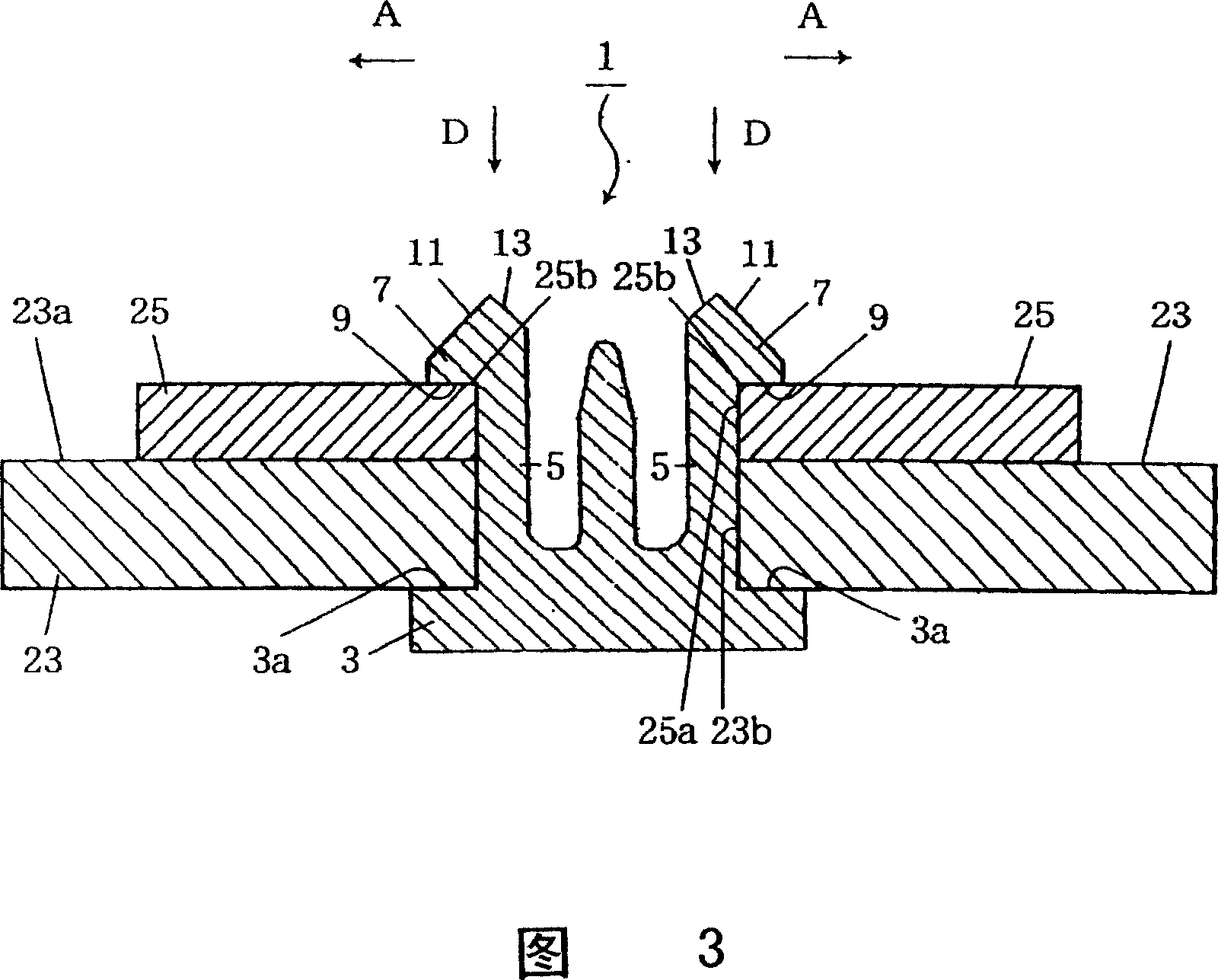

[0017] Fig. 1 is a sectional view showing a snap-fit mechanism according to Embodiment 1 of the present invention, Fig. 2 is a schematic perspective view showing an example of fixing parts of a disc playback device by applying the fitting mechanism shown in Fig. 1 , and Fig. 3 is a diagram Sectional view of line III-III of 2. In addition, this first embodiment is an application example in which two plate-shaped parts (members to be fixed) in a stacked state are fixed through through holes formed in both parts with a common inner diameter.

[0018] As shown in FIG. 1, the snap fit mechanism 1 roughly includes: a plate-shaped base 3 having a planar upper surface (first fixing surface) 3a; There are 4 in 1, but only 2 are shown in Fig. 1 and Fig. 3) elastic tongue 5;

[0019] The engaging claw 7 roughly includes: a side surface (second fixing surface) 9 for fixing a plate-shaped pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com