Shock damper and method for setting the shock damper

A technology of shock absorbing device and shock absorbing unit, which is applied in the direction of spring/shock absorber, mechanical equipment, inertial effect shock absorber, etc., can solve the problems of difficult design and lack of wide applicability, and achieve stable shock absorbing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

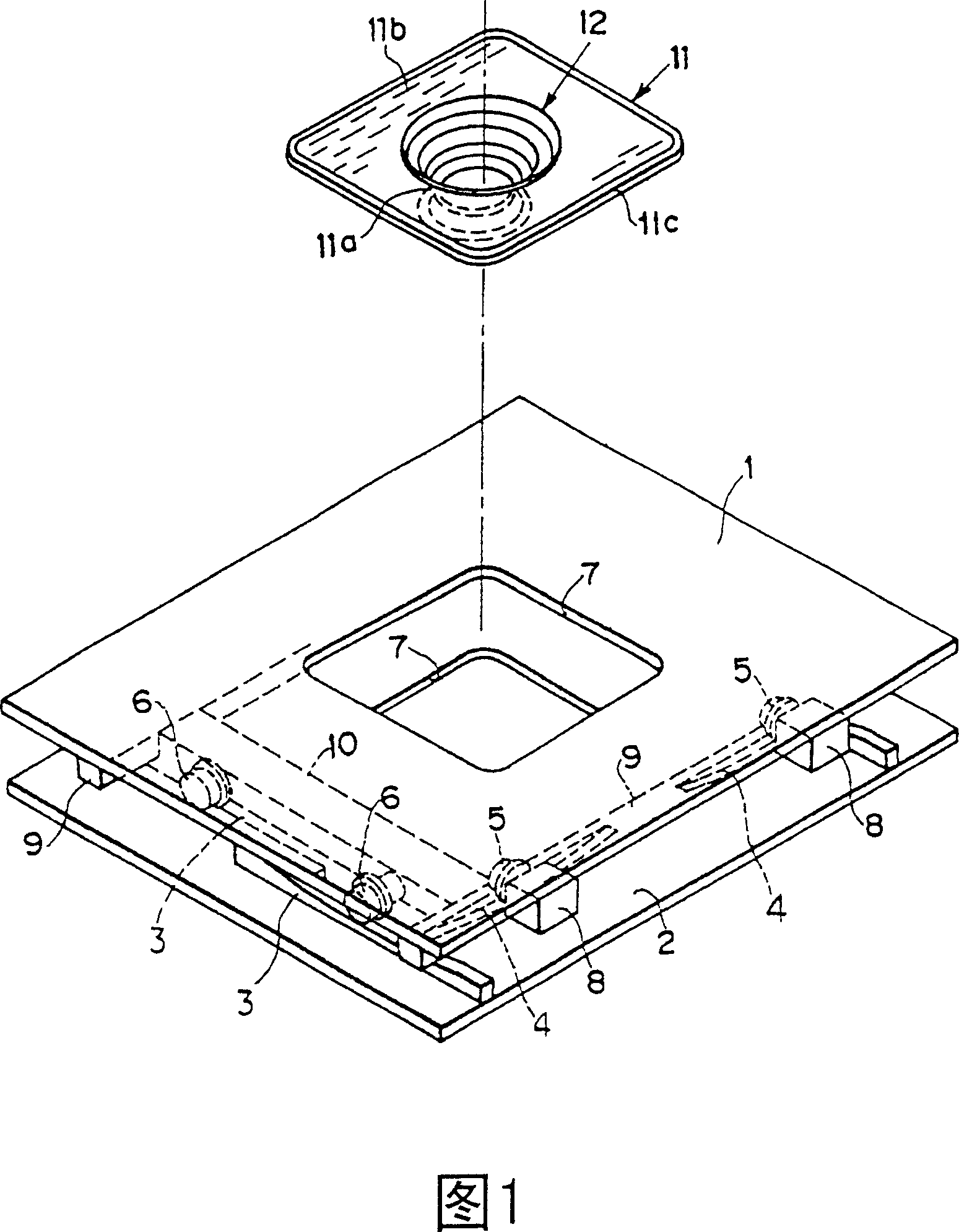

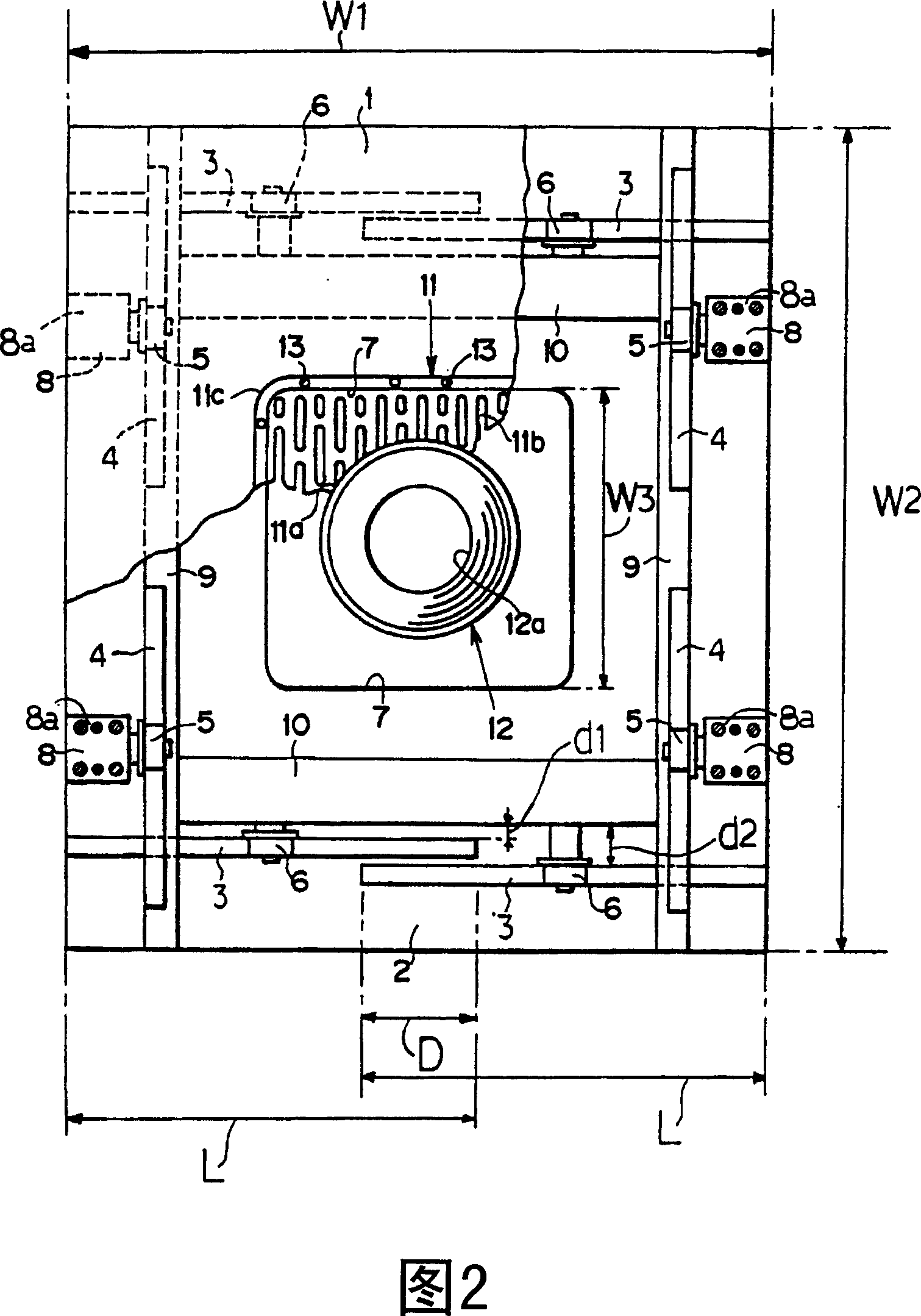

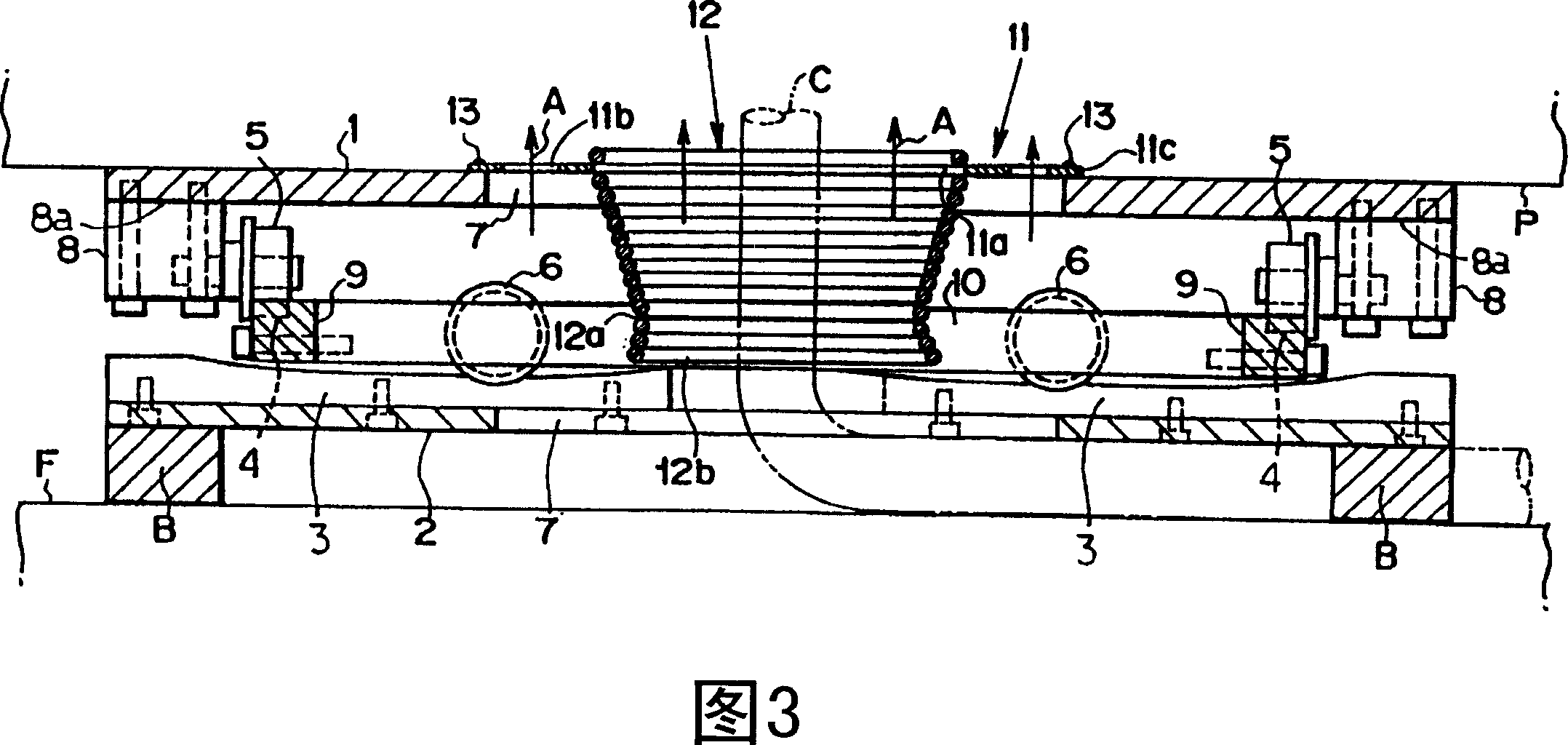

[0116] In Fig. 2 and Fig. 6, the upper platform 1 and the lower platform 2 are formed into a rectangle, and their external dimensions are W2=about 900mm, and W1=about 700mm. The first rail 3 has a rail length L=approximately 400 mm, and is arranged on the lower frame 2 .

[0117] As shown in the present invention, the track frame 9 and the roller frame 10 assembled into a well shape are movably arranged between the upper platform 1 and the lower platform 2, and the opening 7 is opened by the track frame 9 and the roller frame 10. The maximum dimension of W3=approximately 450nm, such a large-sized opening 7 can make the wiring of cables passing through the opening 7 not affect the damping performance.

[0118] In addition, the space formed between the upper platform 1 and the lower platform 2 has a height of about 80 mm. When a server rack (shock-absorbing object P) with a normal size and height of 2000 mm is fixed on the upper platform 1, the distance from the ground F The se...

Embodiment 2

[0196] The external dimensions of each upper frame 1 and lower frame 2 of the shock absorbing units 111, 112 are that the upper frame 1 is a rectangle with W12 = about 400 mm and a longitudinal dimension W11 of about 890 mm. The lower frame 2 is a rectangle with W14 = about 300 mm and a longitudinal dimension W11 of about 890 mm. The first rail 3 has a rail length of about 400 mm and is arranged on the upper frame 1 .

[0197] Damping units 111 and 112 of this structure are installed in the same manner as the installation method in FIG. 20 . The shock-absorbing object P has a square box shape with an outer dimension of about 700 mm, and a wiring device C extending from the ground F is connected to the lower surface side of the shock-absorbing object P.

[0198] Make the approximate center of the upper frame 1 of the shock-absorbing units 111,112, after being positioned at the end of the shock-absorbing object P, use the connecting parts 121,122 of about 1100mm in length to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com