Pressure reducing valve with gauge embedded handle

A technology of gauges and pressure reducing valves, applied in the direction of measuring fluid pressure, measuring fluid pressure through mechanical components, instruments, etc., can solve the problem of not being able to take out the pressure gauge cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

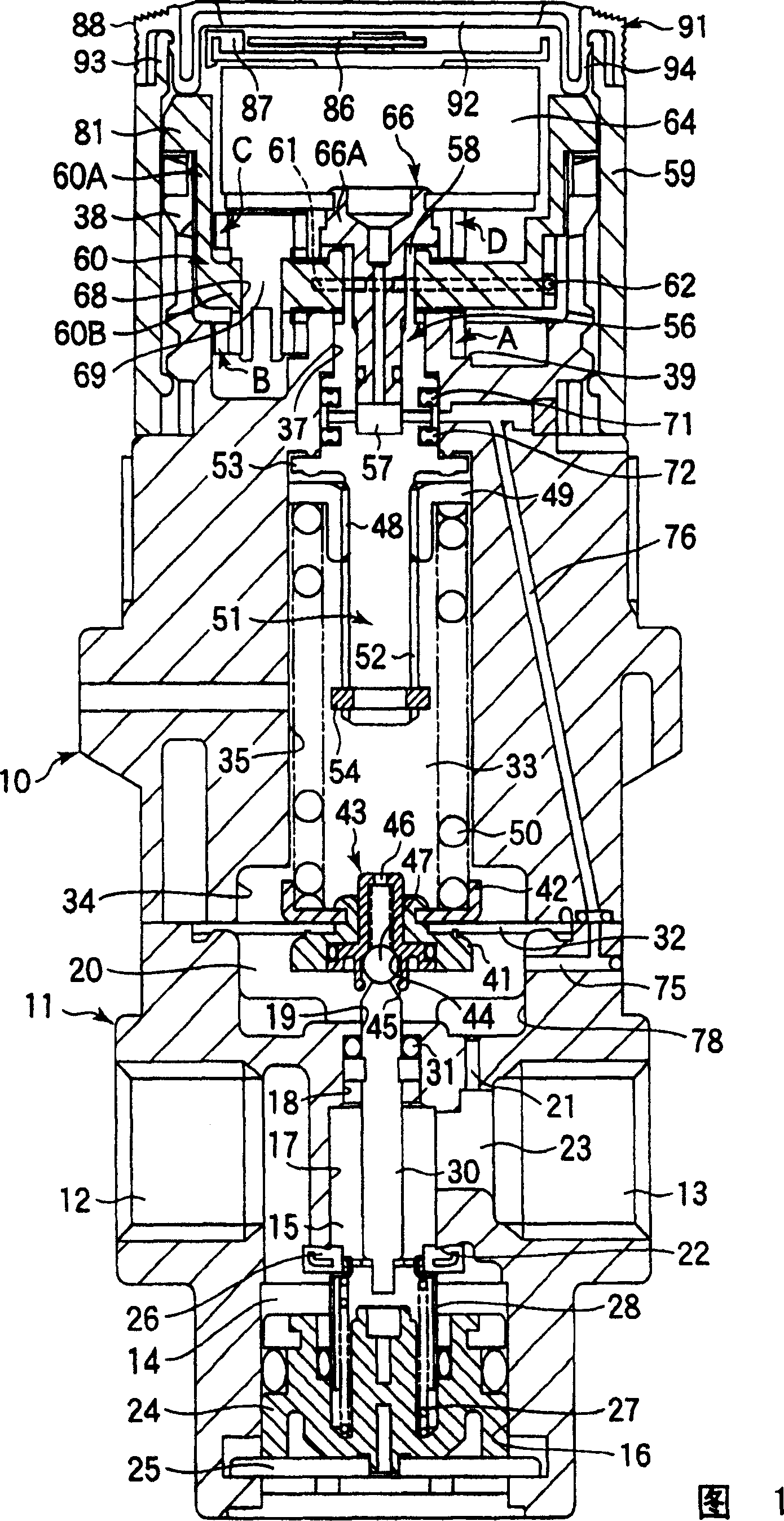

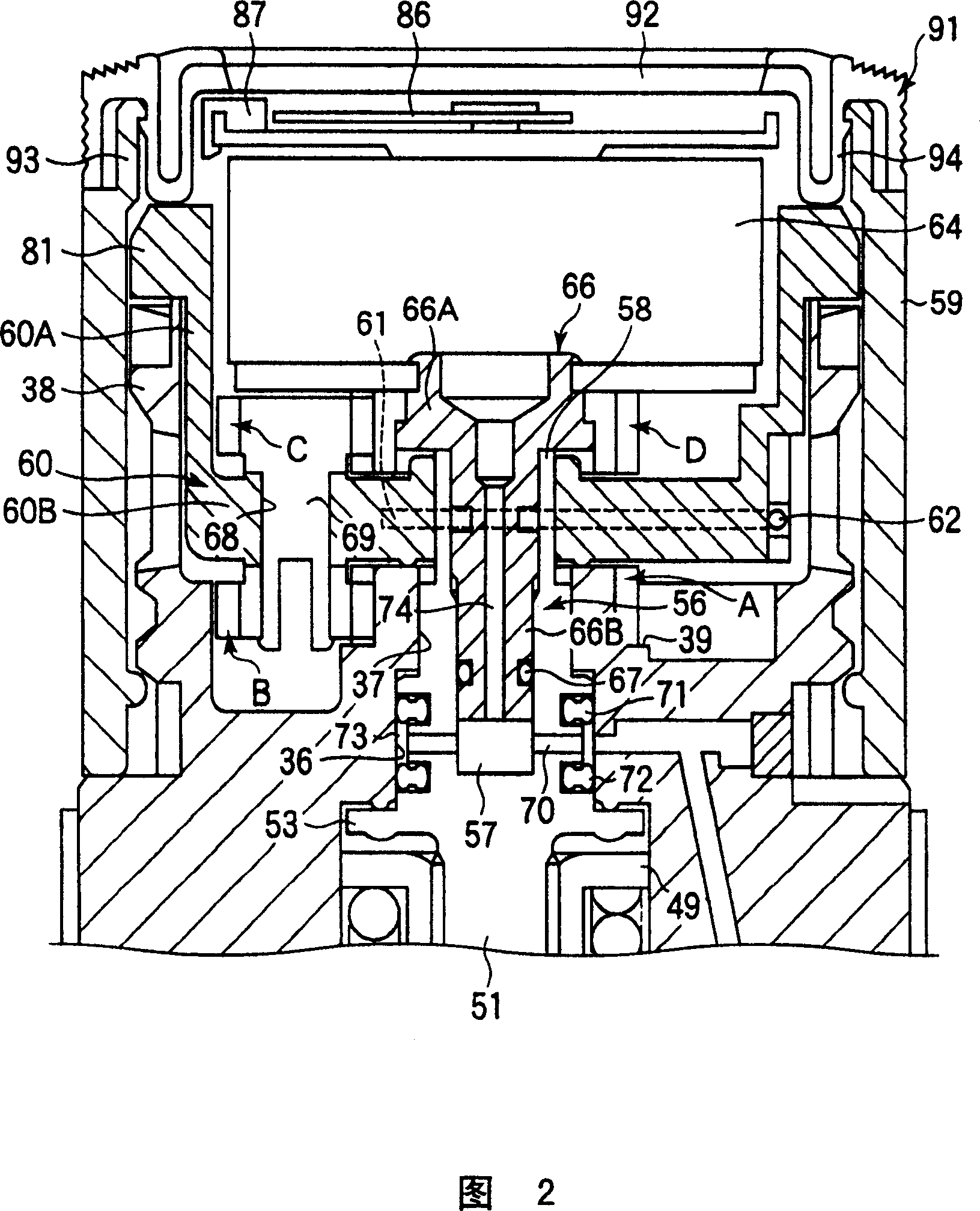

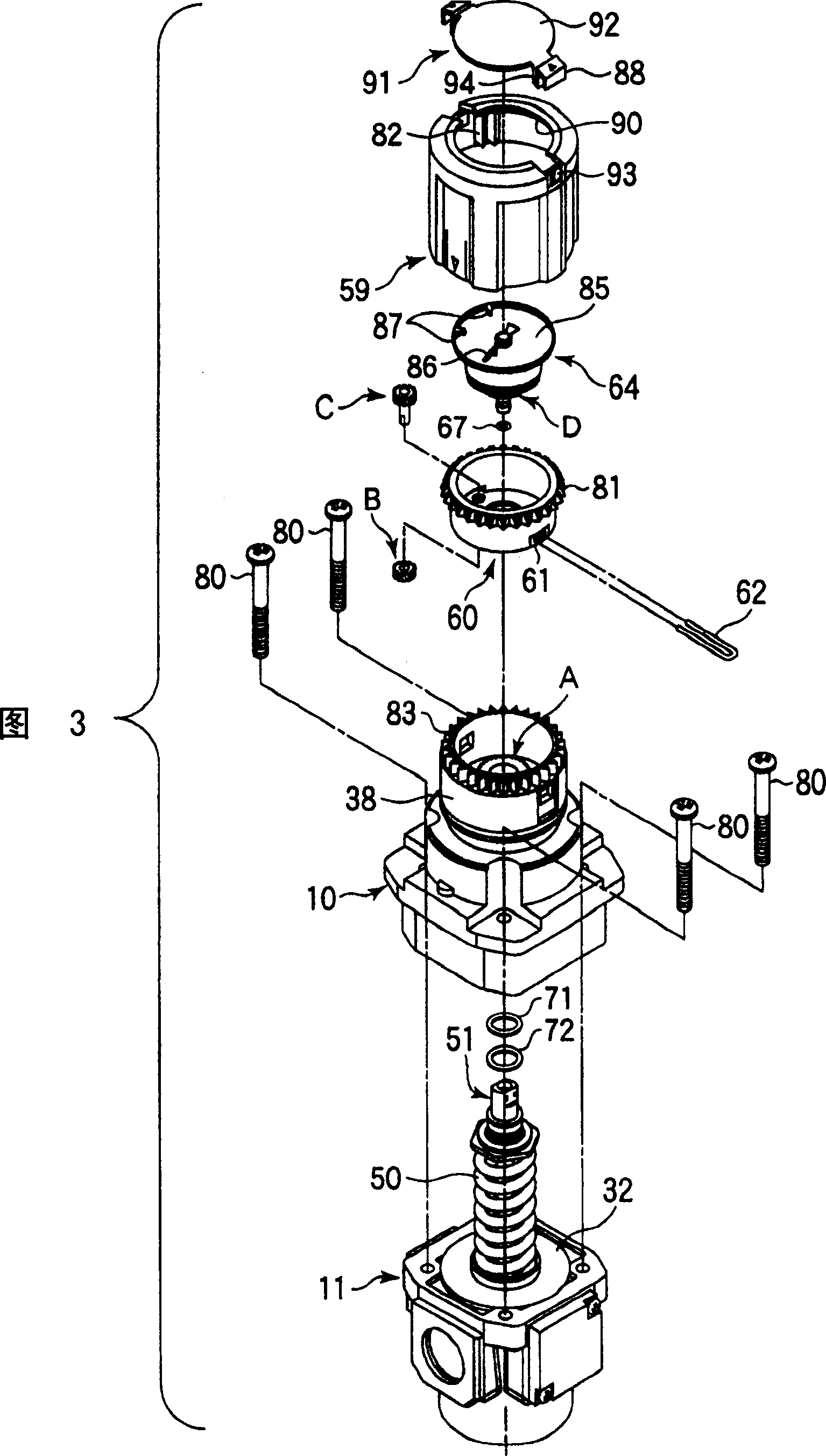

[0021] Figures 1 to 4 show the embodiment of the handle-type pressure reducing valve with gauge of the present invention. In the description of FIGS. 1 to 3 , the term “upper and lower” was used, but if the position of the pressure reducing valve changes, it is conceivable to modify the upper and lower according to the change of its position.

[0022] The valve body is composed of a metal or synthetic resin valve body 11 and a valve cover 10 .

[0023]A primary side port 12 and a secondary side port 13 are formed on the side of the valve body 11, and a valve chamber (primary pressure chamber) 14 and a secondary pressure chamber 15 are formed between the primary side port 12 and the secondary side port 13. . In the central portion of the valve main body 11, a large-diameter hole 16, a middle-diameter hole 17, a small-diameter hole 18, an insertion hole 19, and a feedback chamber hole 78 are sequentially formed from below. Chamber 14 communicates with primary side port 12 . A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com