Internally coated mold, and internal mold coating forming method

A metal mold and coating technology, which is applied in applications, household appliances, household components, etc., can solve the problems of unrevealed fitting parts with grooves, paint leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

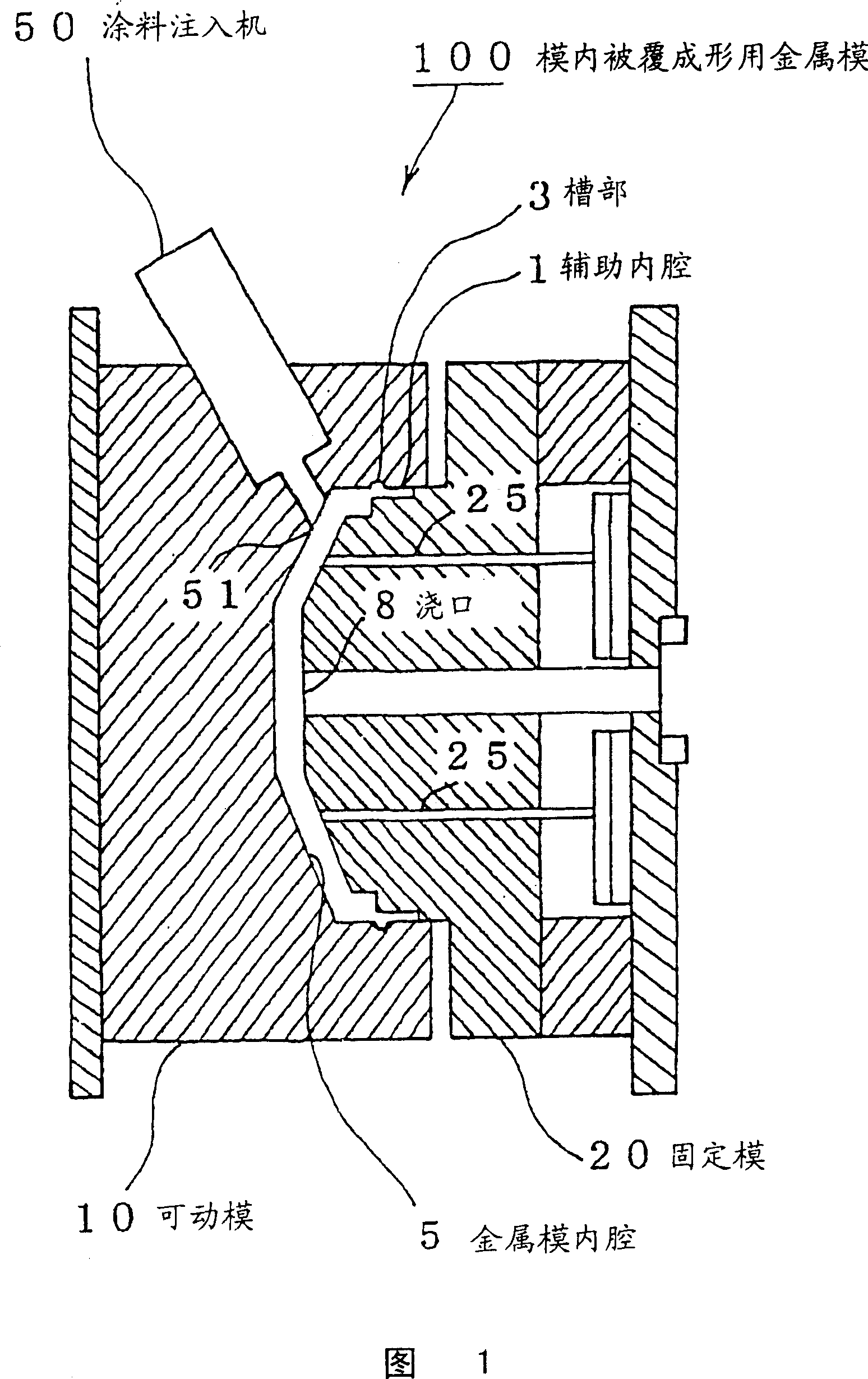

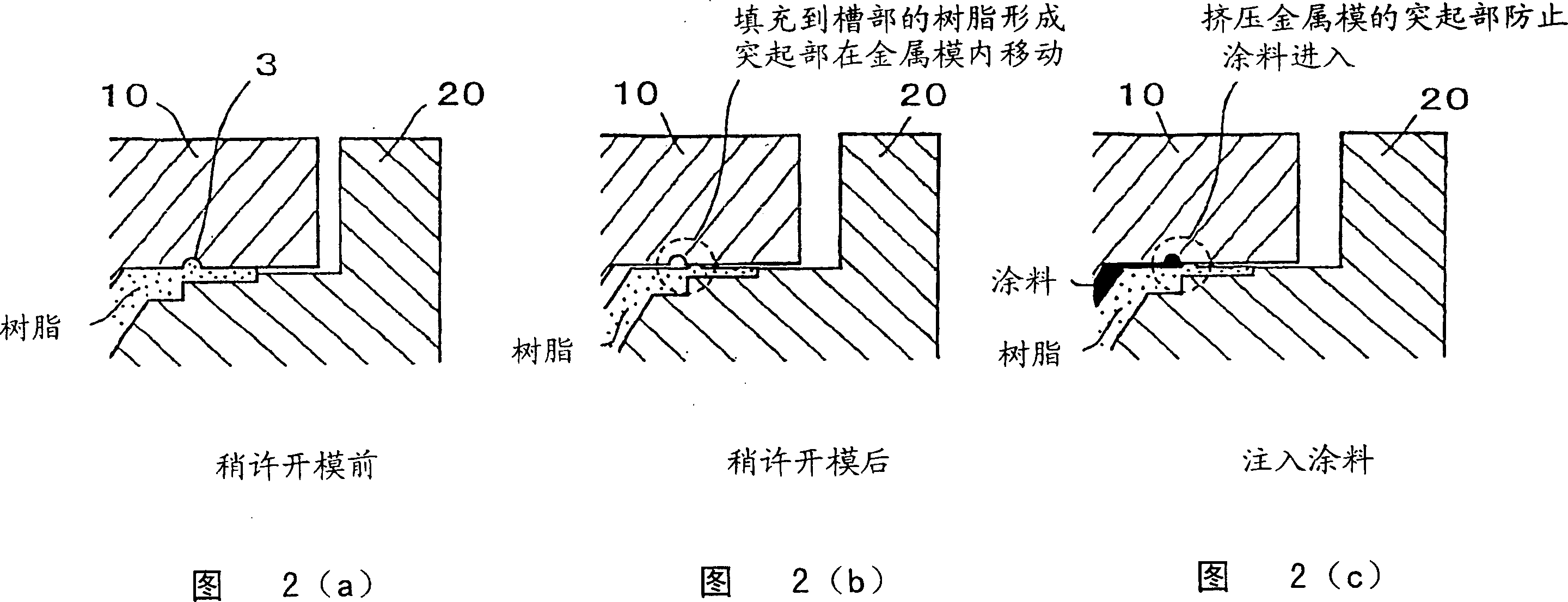

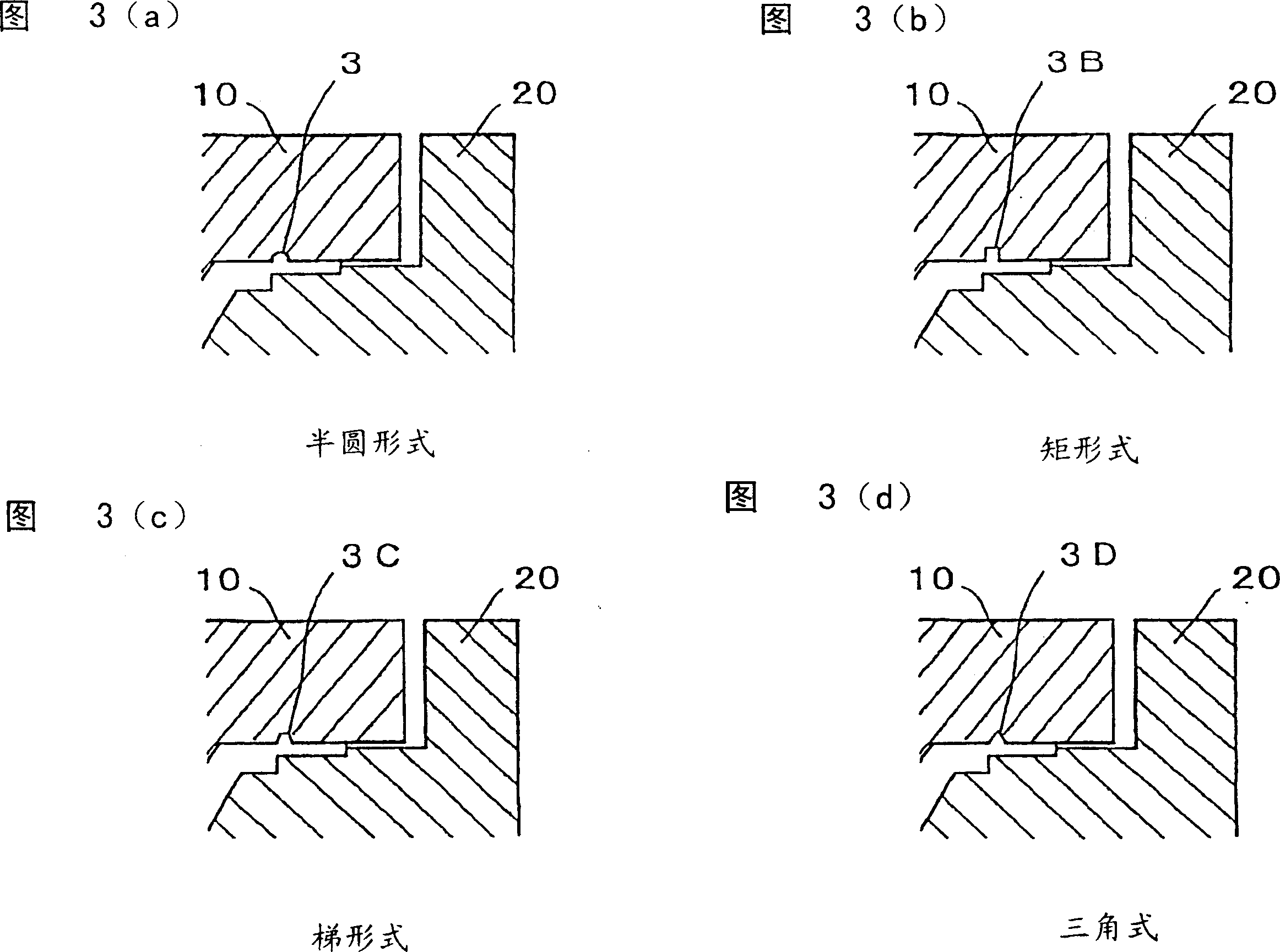

[0042] First, aspects of the present invention will be described. There are broadly two aspects to the invention. The first aspect relates to a metal mold in which grooves are formed around the entire circumference of an end portion of a cavity of a metal mold for in-mold coating molding to prevent paint leakage from occurring, and an in-mold coating molding method using the same. organization. In this aspect, an auxiliary cavity 1 extending along the entire circumference of the inner cavity 5 of the metal mold is formed in the opening and closing direction of the metal mold. The form of forming the groove portion at the position corresponding to the end portion of the inner cavity is also included.

[0043] The second aspect relates to a metal mold for in-mold coating molding, which includes a mold cavity formed by a male mold and a female mold, and an in-mold coating molding method using the metal mold. A paint injection machine for the fitting part of the scissors struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com