Fatigue life safety predicting method for pressure container

A technology for fatigue life and safety prediction, applied to pressure vessels, instruments, fixed-capacity gas storage tanks, etc., can solve problems such as inapplicability, and achieve the effects of good actual agreement, clear physical meaning, and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

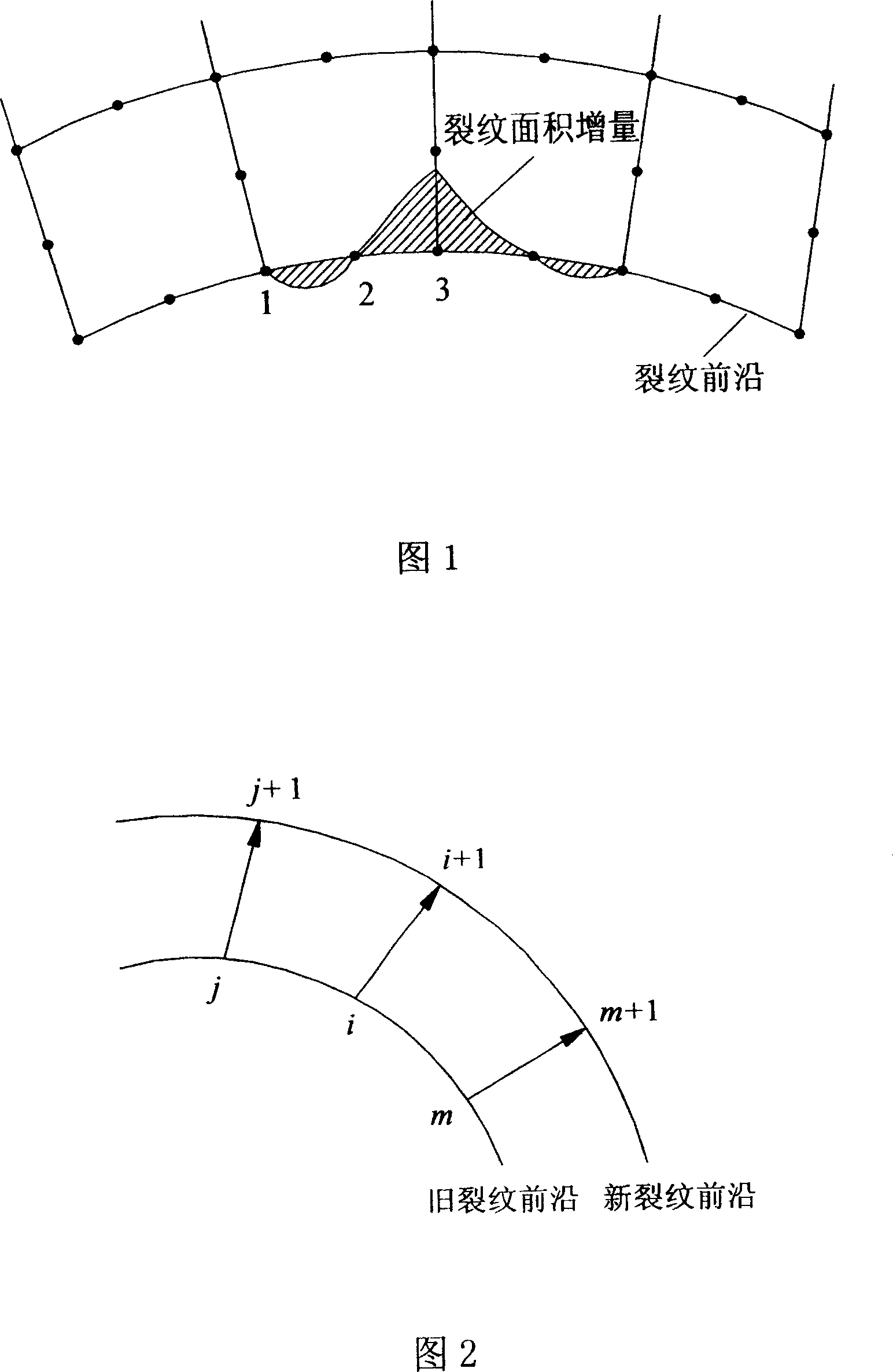

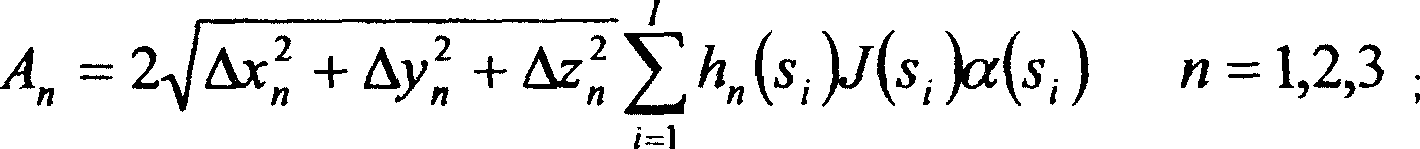

Image

Examples

Embodiment Construction

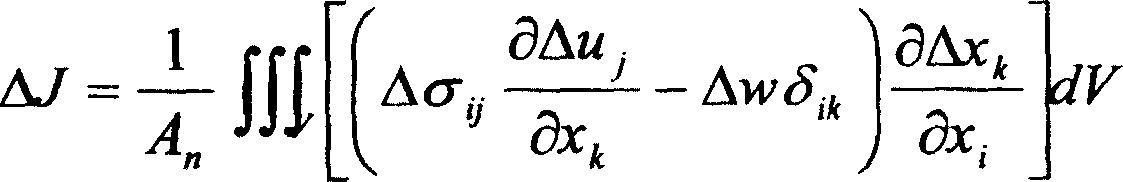

[0024] Firstly, according to the structure, material and force condition of the pressure vessel, the tolerance size of the pressure is obtained, and the tolerance size is stored in the computer database for later use.

[0025] Qualitatively and quantitatively obtain the defect type, position and size of the pressure vessel through non-destructive testing methods (such as ray or ultrasonic testing), and input such initial defect information into the computer; also input the three-dimensional address information about the nodes into the computer.

[0026] From the Paris-Erdogan extension model, it can be expressed by the following formula for the stable crack growth stage:

[0027] da dN = c ( ΔK ) n - - - ( 1 )

[0028] For the crack fatigue growth rate of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com