Laminated photoelectric element and making method thereof

A photoelectric element and laminated technology, applied in the direction of electrical elements, photovoltaic power generation, final product manufacturing, etc., can solve the problems of increased junction, low electromotive force of photoelectric elements, and large interface problems, etc., and achieve low short-circuit current and high conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

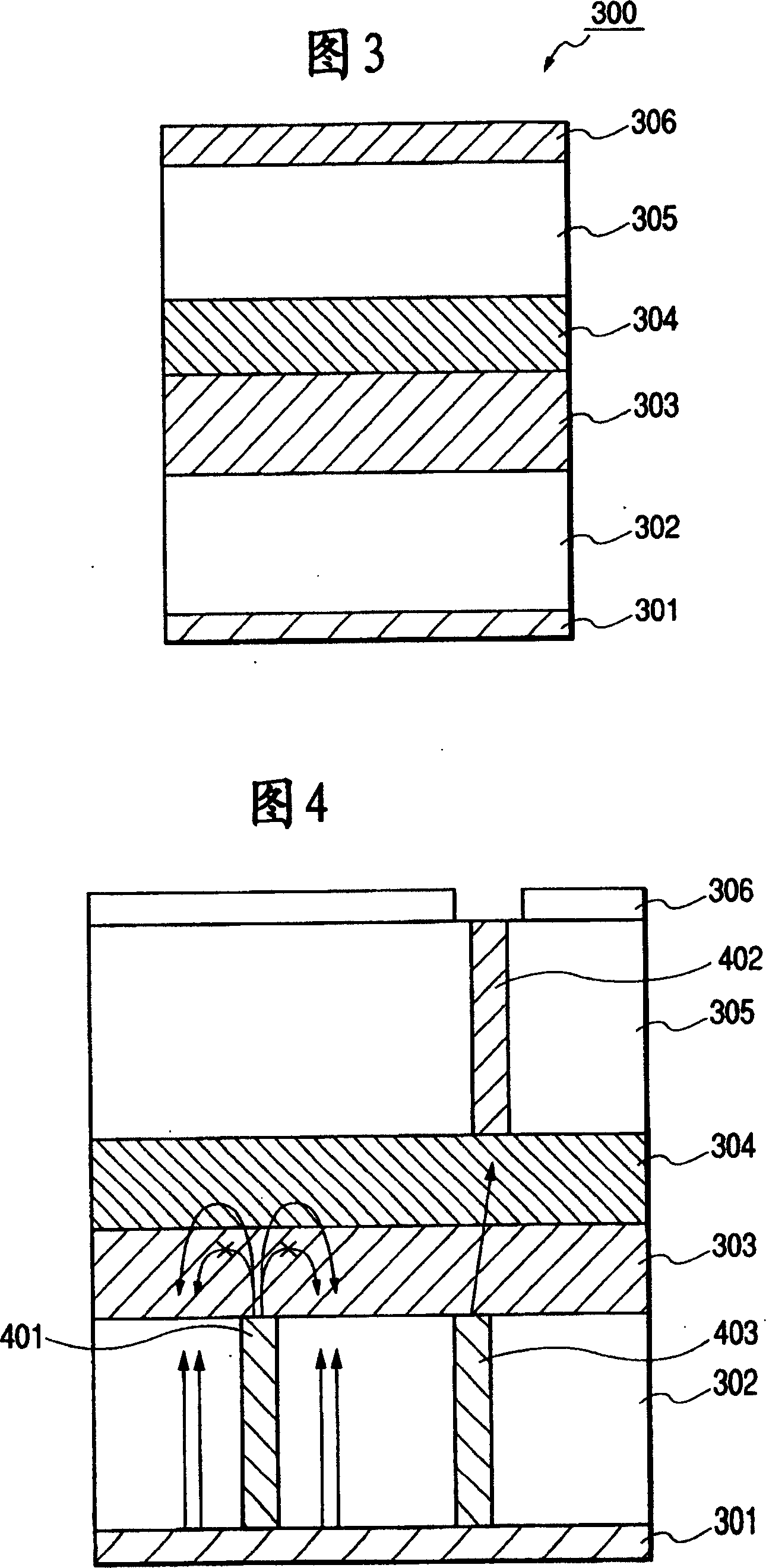

[0099] In this embodiment, a pin-type photoelectric element whose i layer is intrinsic microcrystalline Si is used as the second photoelectric element 302, and a pin-type photoelectric element whose i layer is intrinsic amorphous Si:H is used as the first photoelectric element 305, and An example of the first multi-layer photovoltaic element (see FIG. 3 ) of the present invention was fabricated using zinc oxide as an intermediate layer.

[0100] For the substrate 301, a flat stainless steel (SUS 430) generally called BA standard with a shape of 45 mm x 45 mm in length and width and a thickness of 0.15 mm was used, and it was installed in a commercially available DC magnetron sputtering device (not shown), Exhaust to bring the pressure to 10 -3 Pa or lower.

[0101] After that, with a flow rate of 30cm 3 / min (normal) supply argon to keep the pressure at 2×10 -1 Pa. Without heating the substrate, a 120W DC power was applied to a φ6-inch aluminum target to form a 70nm alumin...

Embodiment 2

[0147] In the same manner as in Example 1, a pin-type photoelectric element whose i layer is intrinsic microcrystalline Si is used as the second photoelectric element 302, and a pin-type photoelectric element whose i layer is intrinsic amorphous Si:H is used as the first photoelectric element 305, and a multilayer photoelectric element using zinc oxide as an intermediate layer (see FIG. 3 ).

[0148] The sample of the zinc oxide layer is produced separately from the photoelectric element, and the target material containing Al is adjusted as it is with oxygen and vaporized H 2 A zinc oxide layer showing the conductivity shown in Table 9 was formed on the quartz plate while increasing the amount of O introduced. From this result, it can be seen that there are conditions for forming a zinc oxide layer having a so-called graded resistivity in which the resistivity changes slowly in the layer thickness direction of the zinc oxide layer.

[0149] In addition, similarly to Example 1...

Embodiment 3

[0158] In Example 3, a pin-type optoelectronic element whose i layer is intrinsic amorphous Si:H is used as the first optoelectronic element, and a pin-type optoelectronic element whose i layer is intrinsic microcrystalline Si is used as the second optoelectronic element, and A third multi-layer photoelectric element of the present invention as shown in FIG. 8, in which indium tin oxide and zinc oxide are laminated as an intermediate layer.

[0159] For the substrate 801 in FIG. 8 , a flat stainless steel (SUS430) generally called BA standard with a shape of 45 mm x 45 mm in length and width and a thickness of 0.15 mm was used, and it was installed in a commercially available DC magnetron sputtering device (not shown). , ventilate to a pressure of 10 -3 Pa or lower.

[0160] After that, with a flow rate of 30cm 3 / min (normal) supply argon to keep the pressure at 2×10 -1 Pa. Without heating the substrate, a 120W DC power was applied to a φ6-inch aluminum target to form a 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com