Integrated insole making process

A manufacturing method and an integrated technology, applied to insoles, shoe-making machinery, footwear, etc., can solve the problems of lowering the price, inability to produce in large quantities, exposing the composition and color of the insole, etc., and achieve the effect of increasing the price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

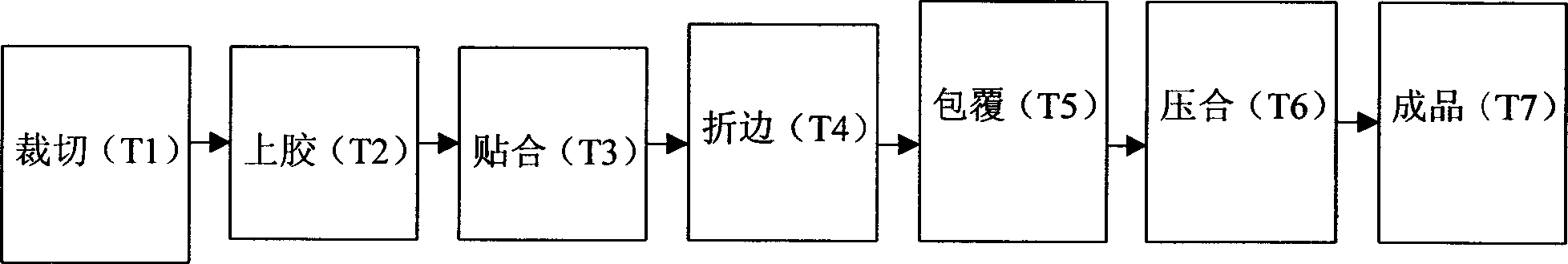

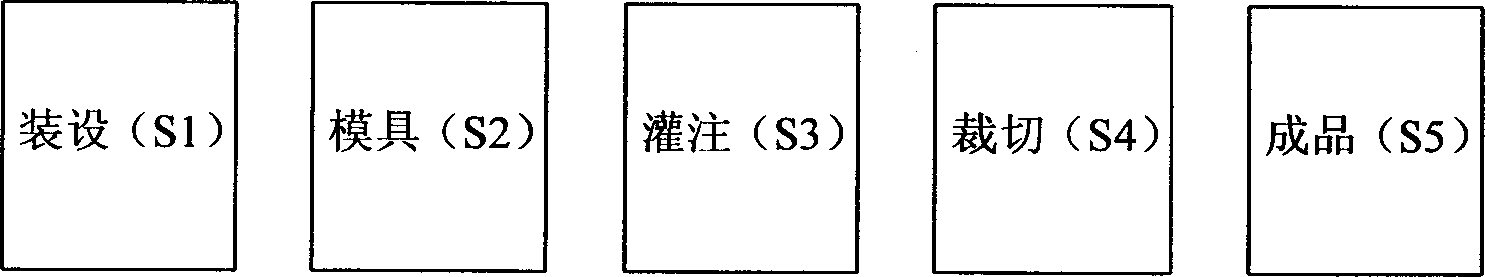

[0034] For a deeper understanding of the present invention, how to achieve the means of the invention, please refer to Fig. 7 to Figure 14 , the present invention mainly includes manufacturing procedures such as device 10 , assembly 20 , pouring 30 , cutting 40 , and finished product 50 .

[0035] Device 10: a layer of covering cloth 60 is placed in the lower mold 60 of the mould, and the lower mold 61 has a mold cavity 62 (sole shape), and a plurality of fixing nails 63 are provided on the outer periphery of the mold cavity 62, The fixing nail 63 fixes the covering cloth 60; in addition, the lower surface of the upper mold 64 is provided with a jacking nail 65 (as shown in Figure 10 ) relative to the mold cavity 62 of the lower mold 61, and the jacking nail 65 can be ( As shown in Figure 11) a round rod, or (such as Figure 12 Shown) jacking nail 66 utilizes one body end face to become concave-convex intermittent guide piece.

[0036] Combination 20: the upper and lower mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap