Sewage treatment device

A drainage treatment device and drainage treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, biological sludge treatment, etc. Effect of deterioration of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

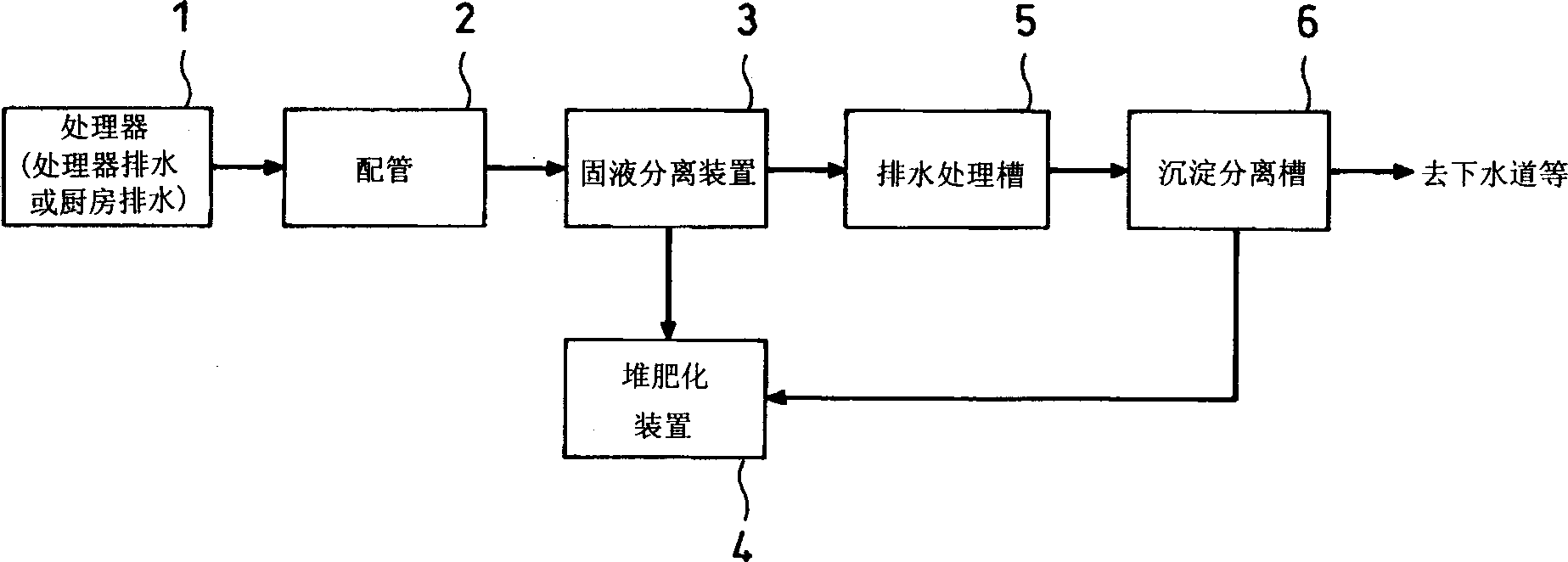

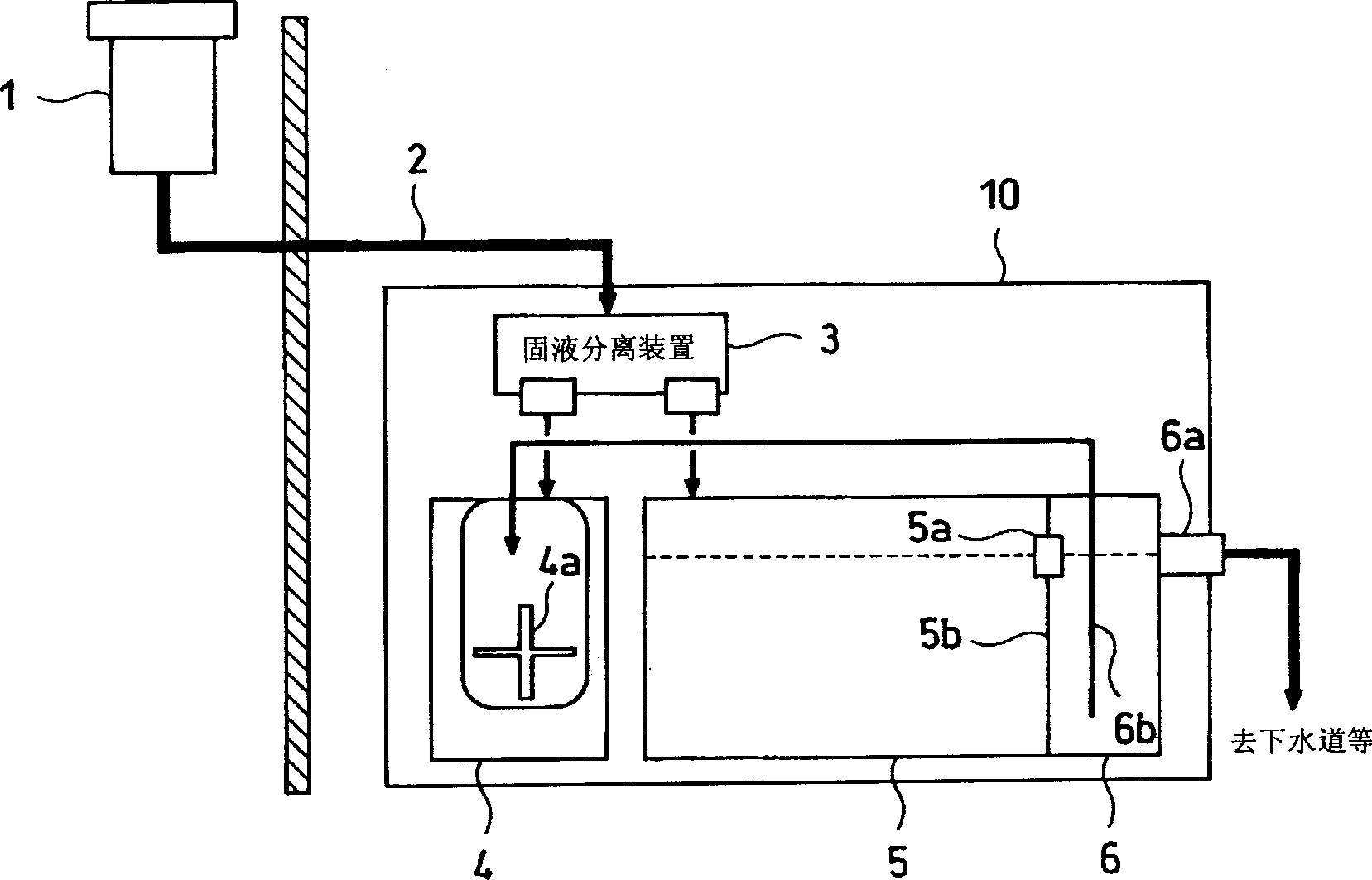

[0022] figure 1 It is a block configuration diagram of a drainage device for a garbage disposer according to an embodiment of the present invention.

[0023] Drainage from the garbage disposer 1 installed on the sink of the kitchen and cooking, etc., which contains pulverized raw garbage and common kitchen drainage, flows into the solid-liquid separation device 3 through the pipe 2 connected to the garbage disposer 1 . That is, this waste water treatment device does not have a flow path switching device and a flow regulating tank, so that the structure thereof is simplified.

[0024] In the solid-liquid separation device 3, when the waste water containing the shredder of raw garbage during use of the garbage disposer flows in, the solid and liquid components are separated. In addition, when flowing into the kitchen drainage when the garbage disposer is not used, it directly enters the drainage treatment tank 5 because it is a liquid component.

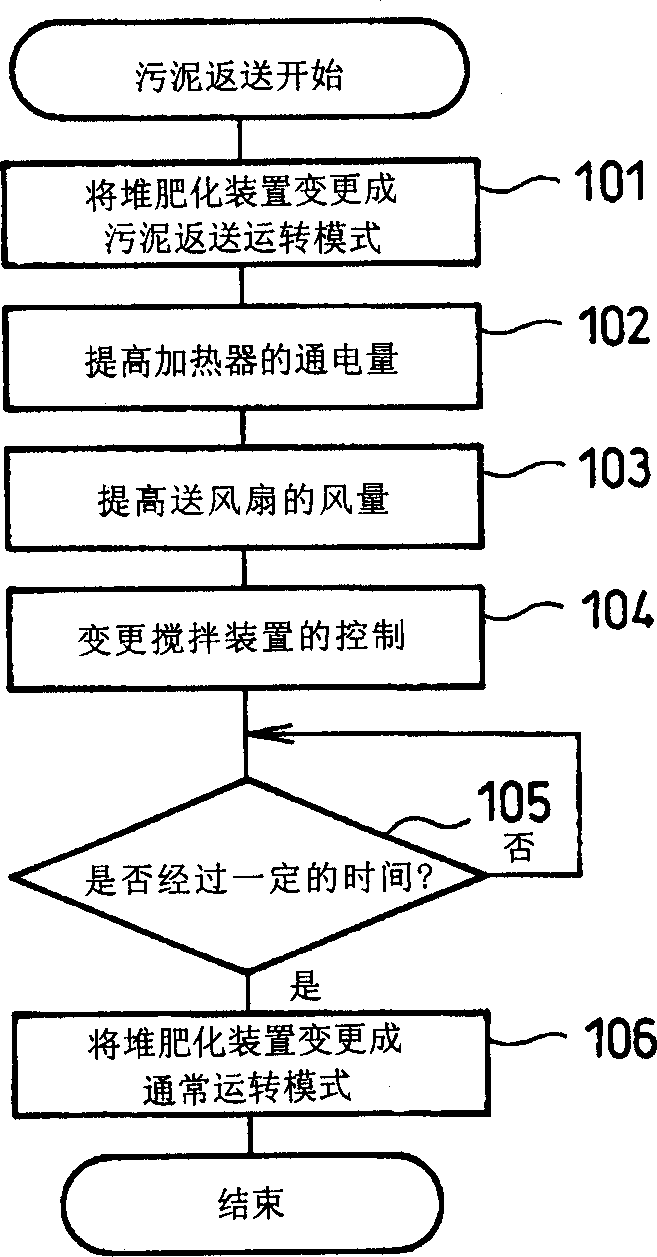

[0025] In the composting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com