Exhaust gas treating tower

A waste gas treatment tower, waste gas technology, applied in the separation of dispersed particles, chemical instruments and methods, use of liquid separation agents, etc., can solve the problems of different flow rates, uneven flow of waste gas, etc., to improve flow rate, contact efficiency, and performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

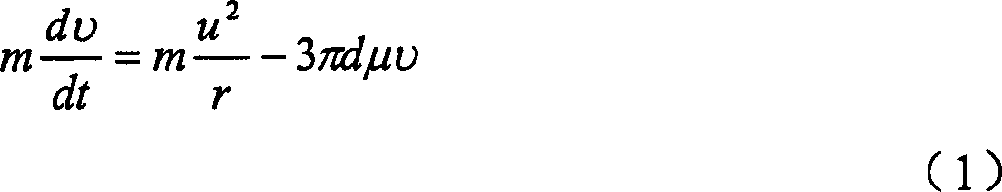

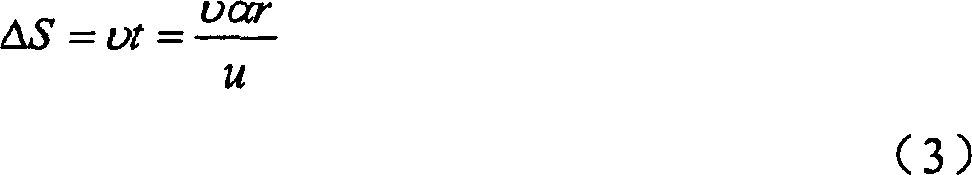

[0069] FIG. 1 is a cross-sectional view illustrating the configuration of an exhaust gas treatment tower 10A in the present embodiment.

[0070] As shown in FIG. 1 , in the exhaust gas treatment tower 10A, the tower main body 11 is, for example, a cylindrical shape with a rectangular cross section, the bottom of which is closed by a bottom plate 12 , and an opening 13 is formed in the upper part. In addition, an introduction port 14 is formed at the lower side of the tower main body 11 to introduce exhaust gas into the tower main body 11 .

[0071] A pipe 16 including a plurality of nozzles 15 is provided in the tower main body 11 . The liquid accumulated at the bottom of the tower main body 11 is sucked up by the pump 17 and supplied to the pipe 16 . The nozzles 15 eject the liquid upward in a columnar shape, and these nozzles 15 are arranged at an appropriately set interval so that a gap is formed between the liquid columns C ejected upward from the nozzles 15 adjacent to e...

no. 2 approach

[0084] Next, an example of the case where the spray nozzle (nozzle) 30 is added to the exhaust gas treatment tower 10B will be shown. In addition, since the basic configuration of the exhaust gas treatment tower 10B is the same as that of the above-mentioned first embodiment, the same reference numerals are used, and the description thereof will be omitted.

[0085] As shown in FIG. 5 , a pipe 31 including a plurality of spray nozzles 30 is provided in a portion below the nozzle 15 and above the inlet 14 of the tower main body 11 of the exhaust gas treatment tower 10B.

[0086] A booster pump (pump) 33 is connected to the piping 31 to boost the pressure of the liquid sucked up from the bottom of the column main body 11 by the pump 17 . Moreover, it is also possible to form the following structure: the pump 17 and the booster pump 33 are not equipped in two stages, and the liquid is directly sucked up from the bottom of the tower main body 11 by the booster pump 33, but in this...

no. 3 approach

[0095] Next, an example of a case where both the droplet generation member 20 and the spray nozzle 30 are combined and installed in the exhaust gas treatment tower 10C will be shown. Furthermore, since the basic configuration of the exhaust gas treatment tower 10C is the same as that of the above-mentioned first and second embodiments, the same reference numerals are used, and description thereof will be omitted.

[0096] As shown in FIG. 7 , a pipe 31 provided with a plurality of spray nozzles 30 is provided in a portion below the nozzle 15 and above the inlet 14 of the tower main body 11 of the exhaust gas treatment tower 10C. Furthermore, the droplet generation member 20 is provided in a portion below the spray nozzle 30 of the exhaust gas treatment tower 10C and above the introduction port 14 .

[0097] In this configuration, the liquid sprayed upward from the nozzle 15 forms a liquid column C and falls downward. Then, the falling liquid collides with the upper surfaces 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com