Pull stem hi-lite pin with pull groove for swaging collars

一种紧固件、模锻的技术,应用在螺纹紧固件、连接构件、螺钉等方向,能够解决增加航空器生产费用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

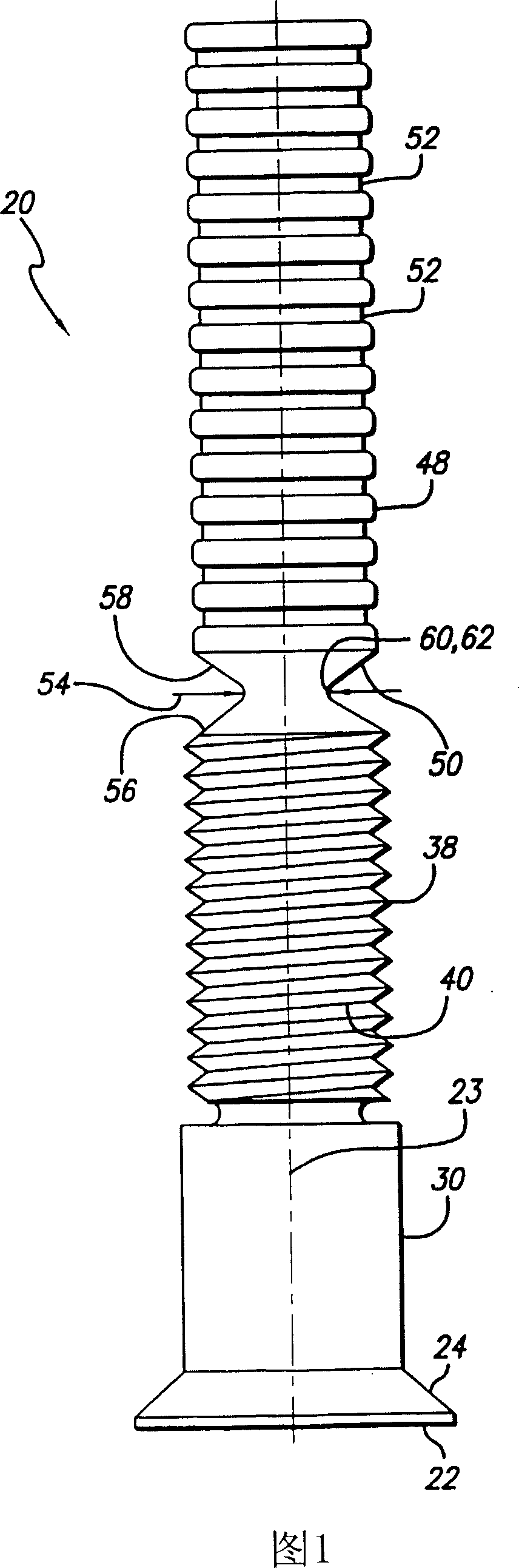

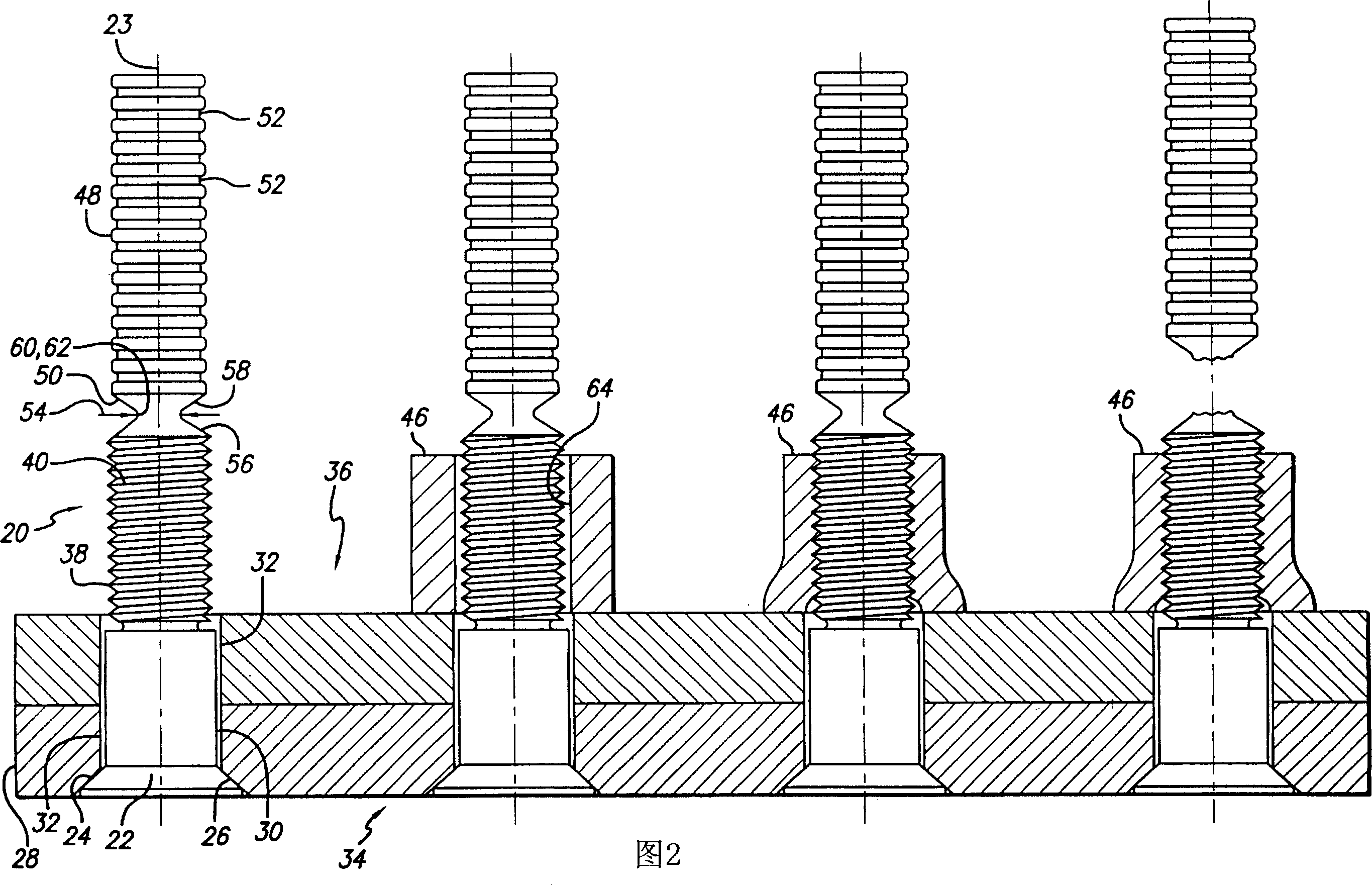

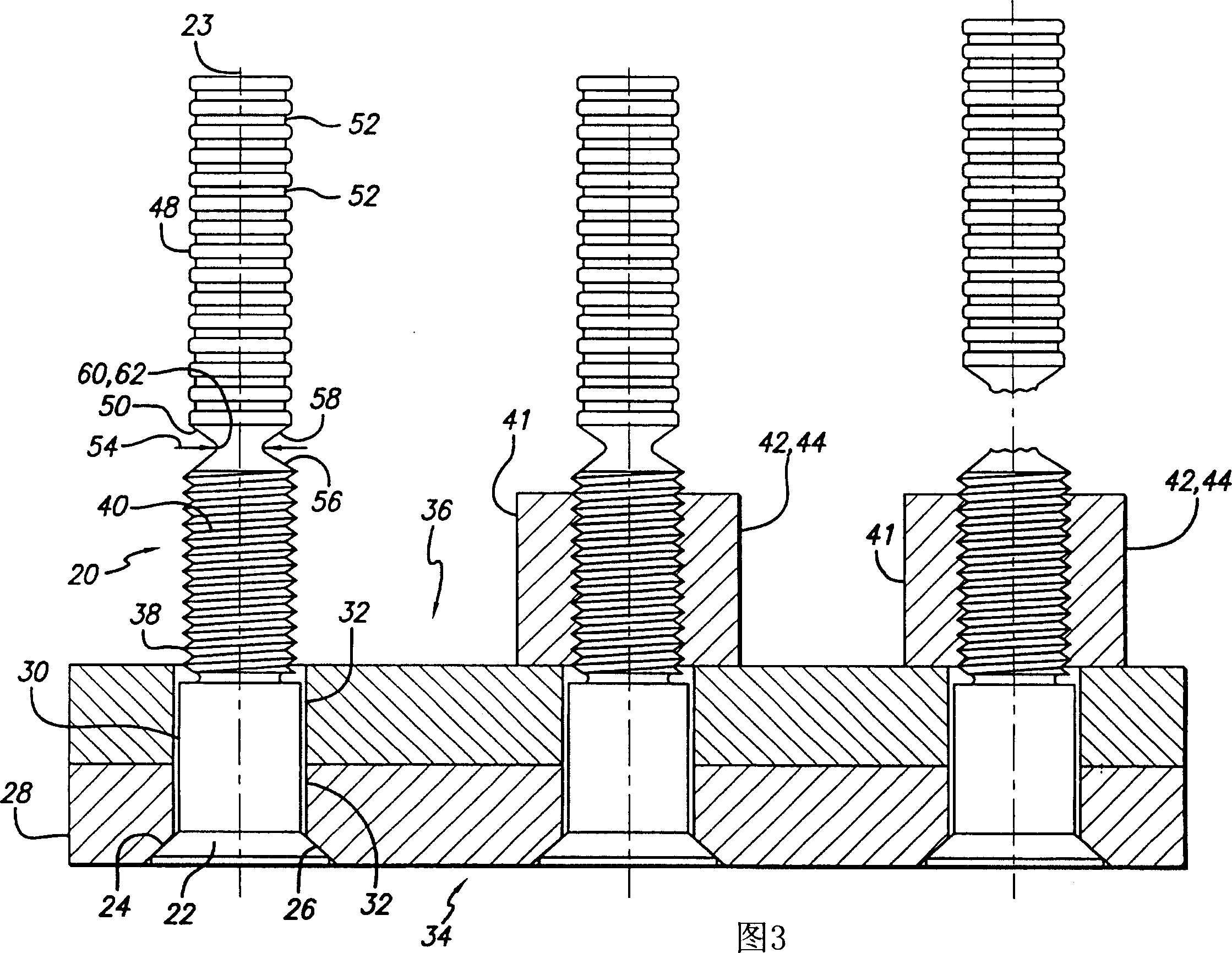

[0027] As shown in the drawings for illustrative purposes, the invention is implemented as a fastener having a threaded shaft portion and a tie rod portion. The fastener may be mounted to at least one workpiece by swaging a collar onto the threaded shaft portion or by threading an internally threaded device such as a nut or threaded collar onto the threaded shaft portion. Referring to the drawings, wherein like reference numerals are used to designate like or corresponding elements throughout the several views, FIG. 1 depicts a tie rod fastener 20 of the present invention. Fastener 20 includes an enlarged protruding head substantially concentric with longitudinal axis 23 of the fastener and located at the proximal end of the fastener. The head may include a distal face 24 adapted to contact a surface 26 of a workpiece 28 (FIG. 2). Although the head 22 is depicted in FIG. 1 as having a flat head configuration, the present invention is not limited to such configurations but may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com