Internal cutter of electric rotary shaver and electric rotary shaver

An electric rotary, shaver technology, used in metal processing and other directions, can solve problems such as difficult hair removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

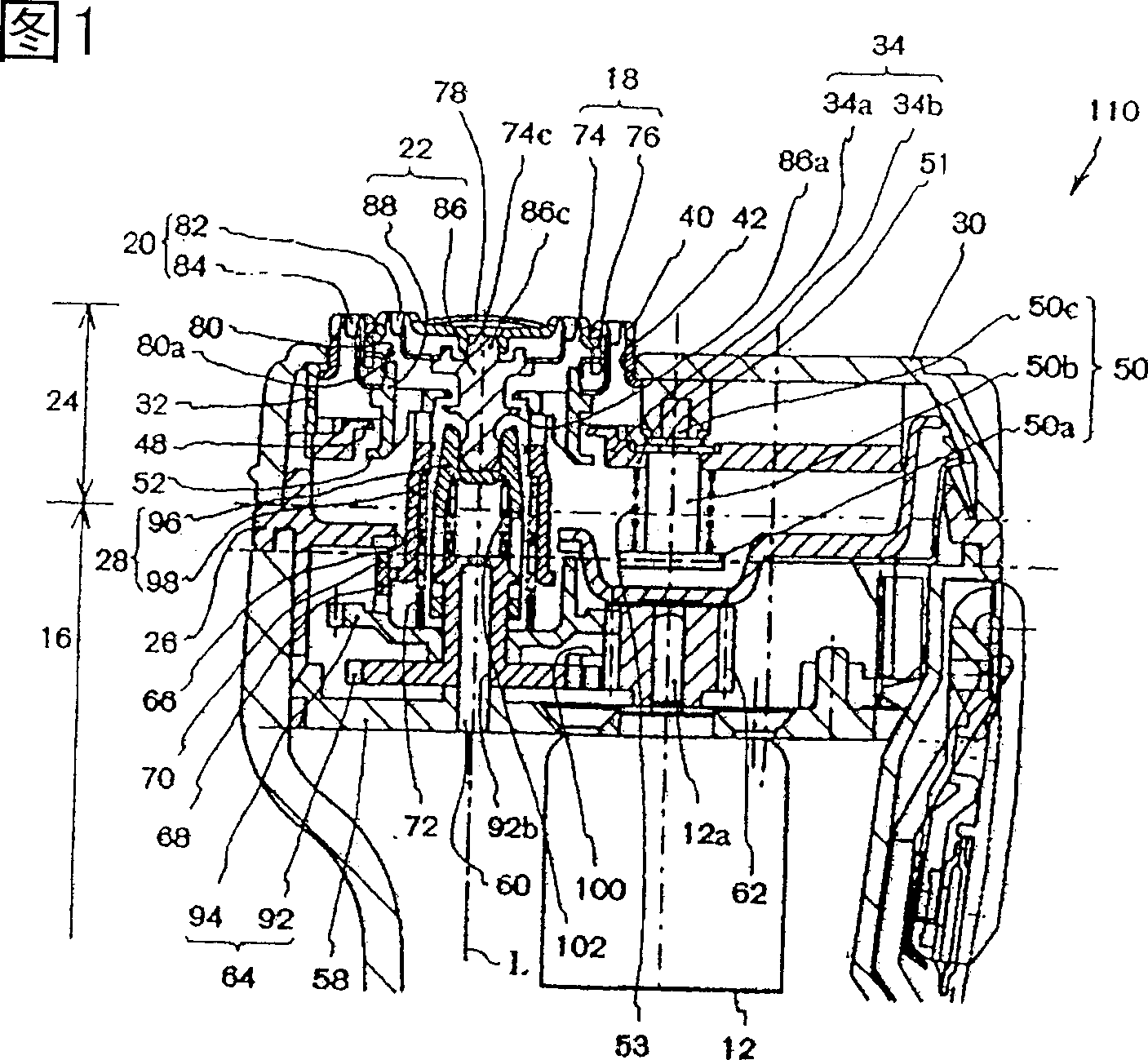

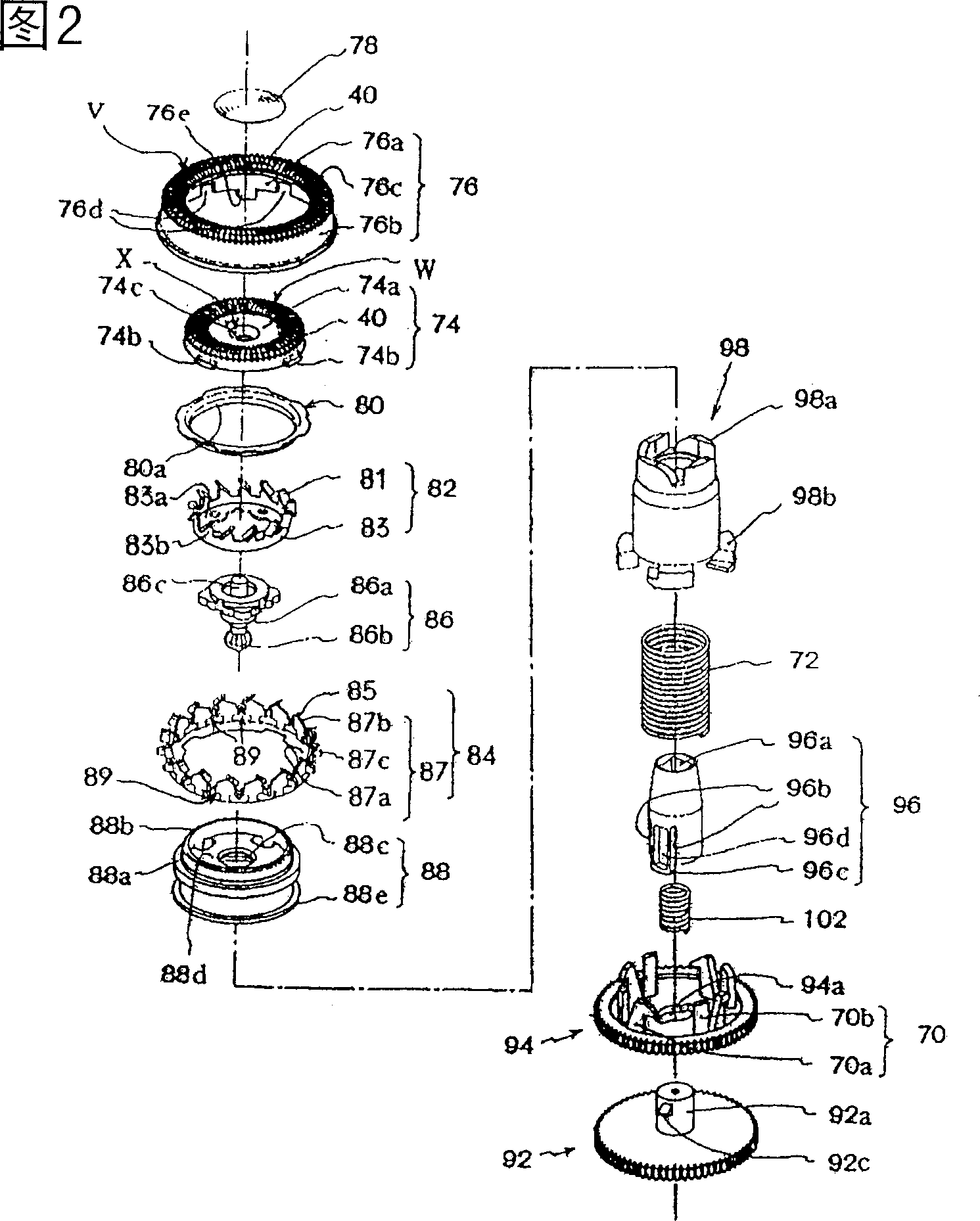

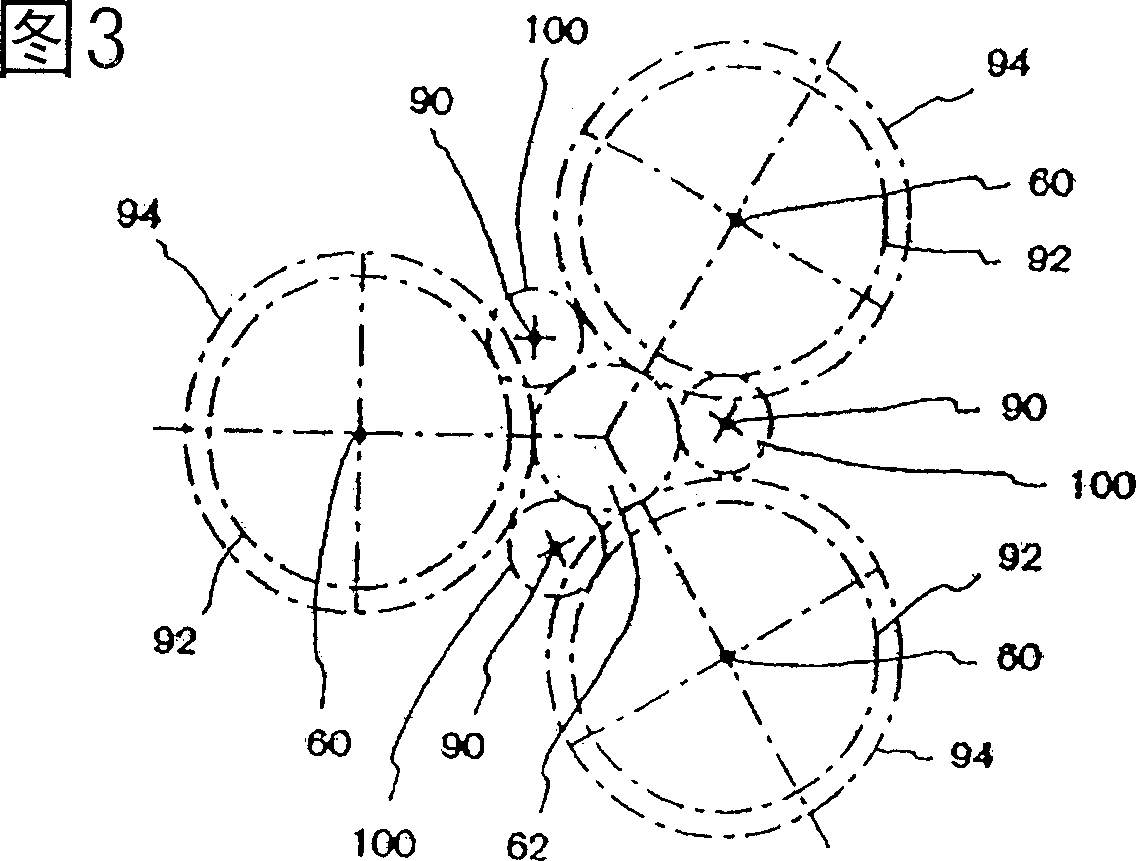

[0083] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The same structures as in the conventional electric rotary shaver 10 are denoted by the same reference numerals, and a detailed description of such structures is omitted.

[0084] First of all, the overall appearance of the electric rotary shaver in this embodiment is basically the same as Figure 7 Same as conventional electric rotary shavers shown. However, the internal structure of the razor of the present invention is different from conventional razors. Therefore, the electric rotary shaver of the present invention will be described with reference to conventional shaver Figure 7 and Figure 1 for description.

[0085] The electric shaver 10 is composed of a main body casing 16 and a cutter head section 24, the cutter head section is detachably mounted on the upper part of the main body casing 16 and accommodates the outer cutter 18, the inne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap