Disc drive, rigid disc drive and casing for rigid disc drive

A technology of hard disk drives and drive devices, which is applied in the direction of driving/moving recording heads, instruments, and planar recording carrier equipment, etc., to achieve the effects of reducing disk jitter, reducing disk jitter, and stabilizing turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described with reference to the drawings.

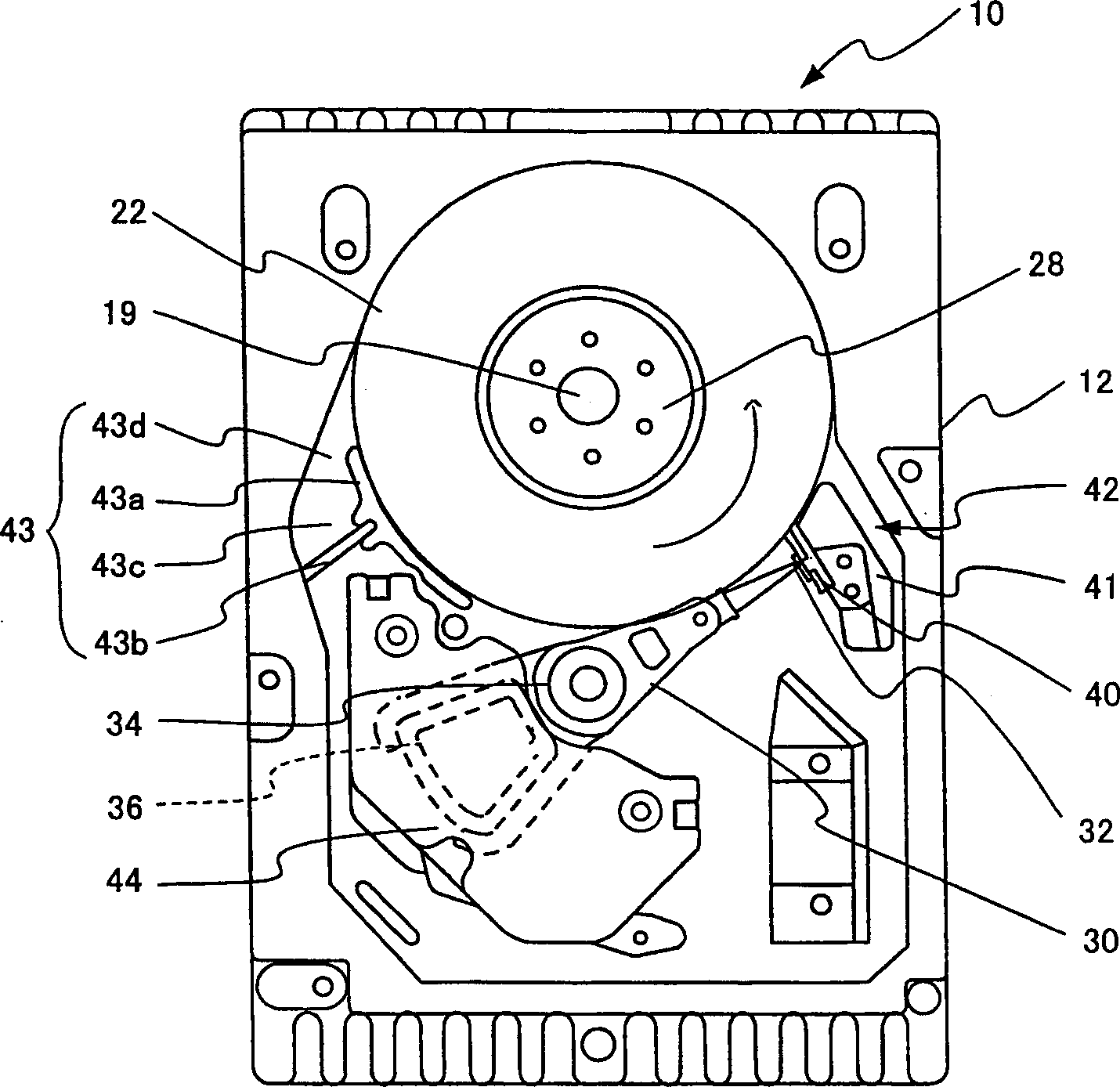

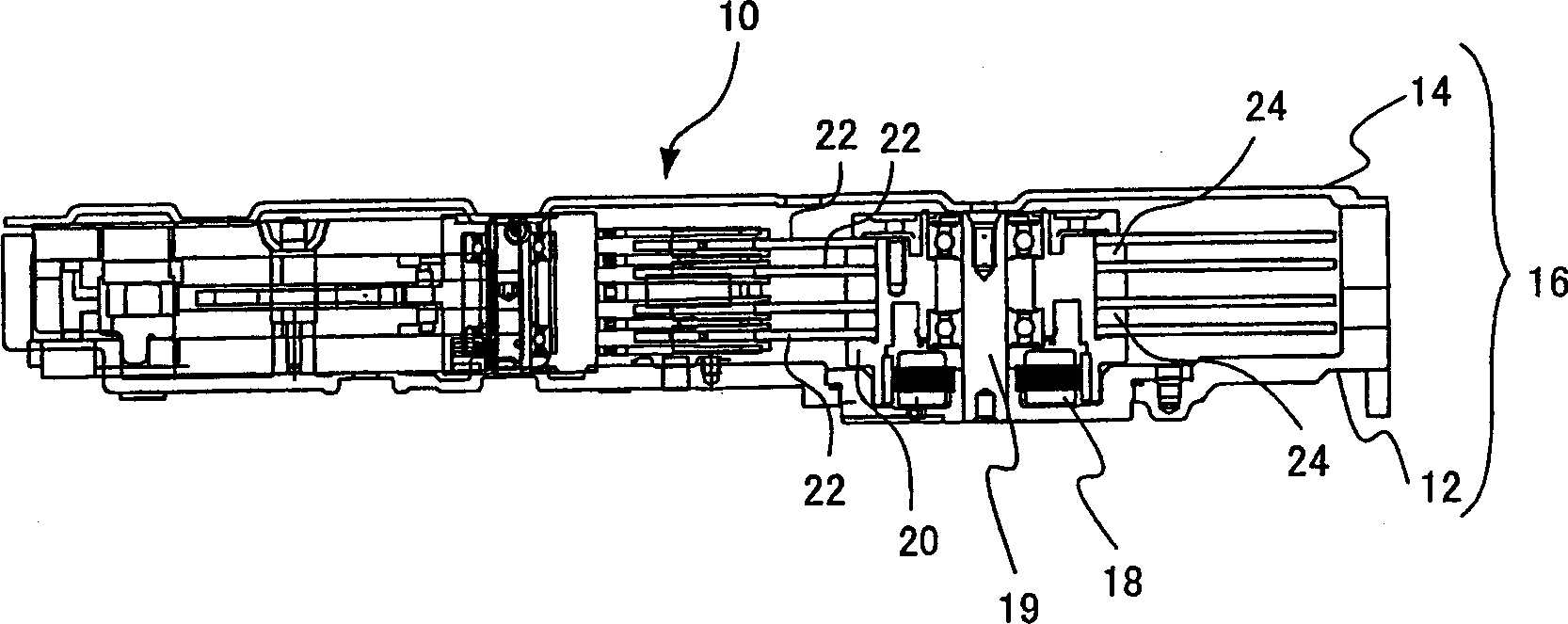

[0035] figure 1 is a plan view of a hard disk drive (HDD) 10 according to this embodiment of the present invention, and figure 2 yes figure 1 A side view of HDD 10 is shown. The HDD 10 is a head load / unload type HDD. In addition, the HDD 10 has a 3.5-inch form factor and is rated at 15,000 rpm to increase data read / write speed.

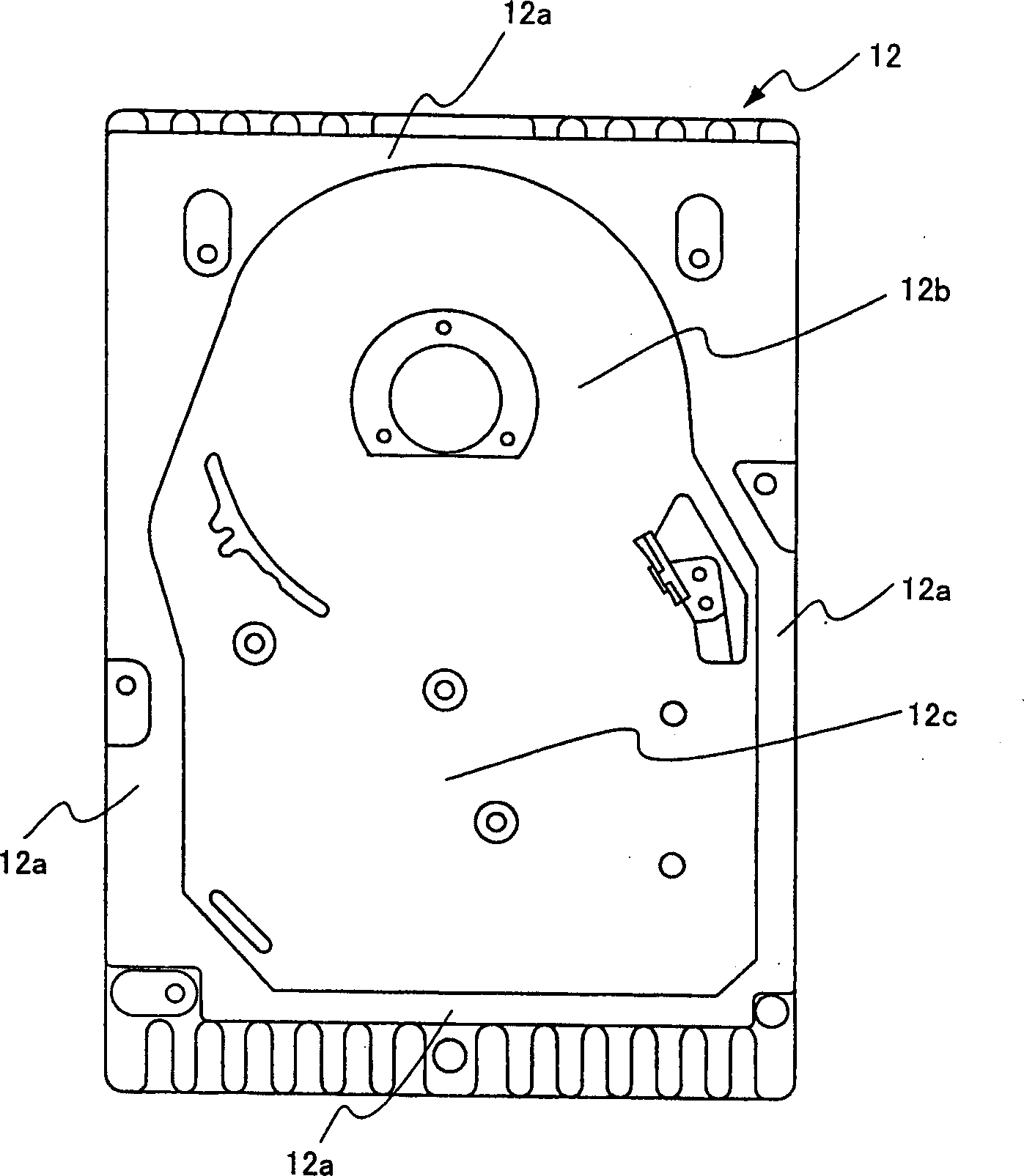

[0036] Such as figure 1 As shown, the HDD 10 forms a disk case 16 by sealing the upper portion of the opening of the shallow box-shaped aluminum alloy base 12 with a top cover 14 (not shown in this figure).

[0037] The top cover 14 is screwed to the base 12 through a rectangular frame-shaped sealing member (not shown) by which the inside of the disk case 16 is made airtight.

[0038] Inside the disk housing 16 , a spindle motor 18 with a built-in bushing structure is arranged at the center of the base 12 . On the top surface of the shaft sleeve 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com