End closure modules for multi-cell pressure vessels, and pressure vessels and vehicles containing same

A pressure vessel and capping technology, applied in the field of structure and construction of end capping assemblies, can solve problems such as expensive tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

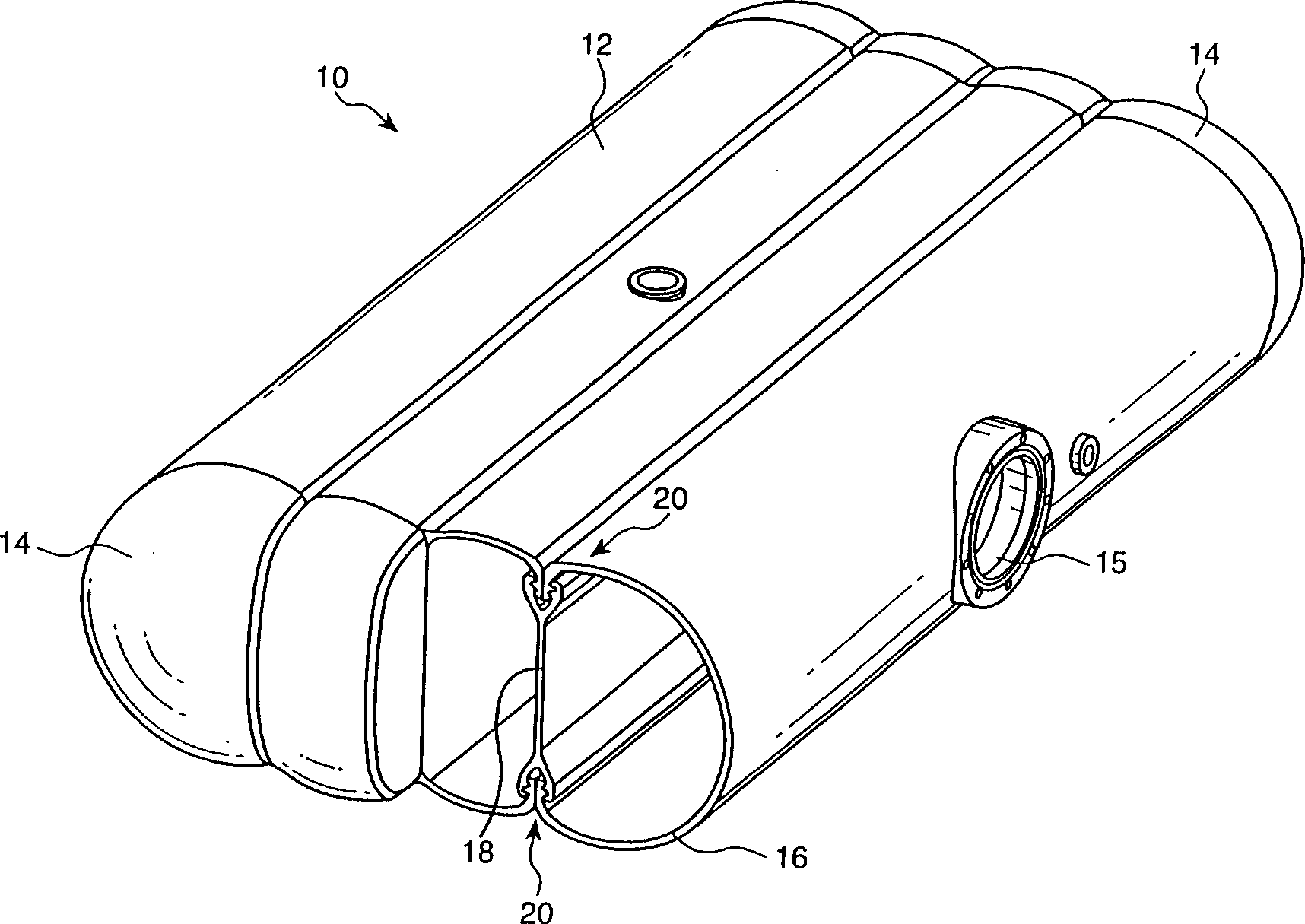

[0025] see now especially figure 1 , one embodiment of the multi-chamber pressure vessel of the present invention is generally indicated by numeral 10 in the drawings. The pressure vessel 10 includes a multi-chamber vessel body (or body portion) 12 and sets of closure assemblies 14 . The main body portion 12 preferably has a substantially uniform cross-section with an inlet 15 therein.

[0026] Body portion 12 may be configured according to any design known to those skilled in the art. According to a preferred embodiment of the present invention, the main body portion 12 generally includes several arcuate outer wall portions 16 . The outer wall portion 16 is connected to an inner web portion 18 . In the described embodiment, the several cavities are each formed from a combination of at least one inner web portion and at least one arched outer wall portion. As is known in the art, the inner web portion 18 may have channels (not shown) shaped to penetrate the inner web port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com