Low-noise hydraulic planger pump with energy accumulator

A technology of hydraulic plunger pumps and accumulators, which is applied in the direction of pumps, multi-cylinder pumps, machines/engines, etc., and can solve problems such as poor adaptability and poor adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

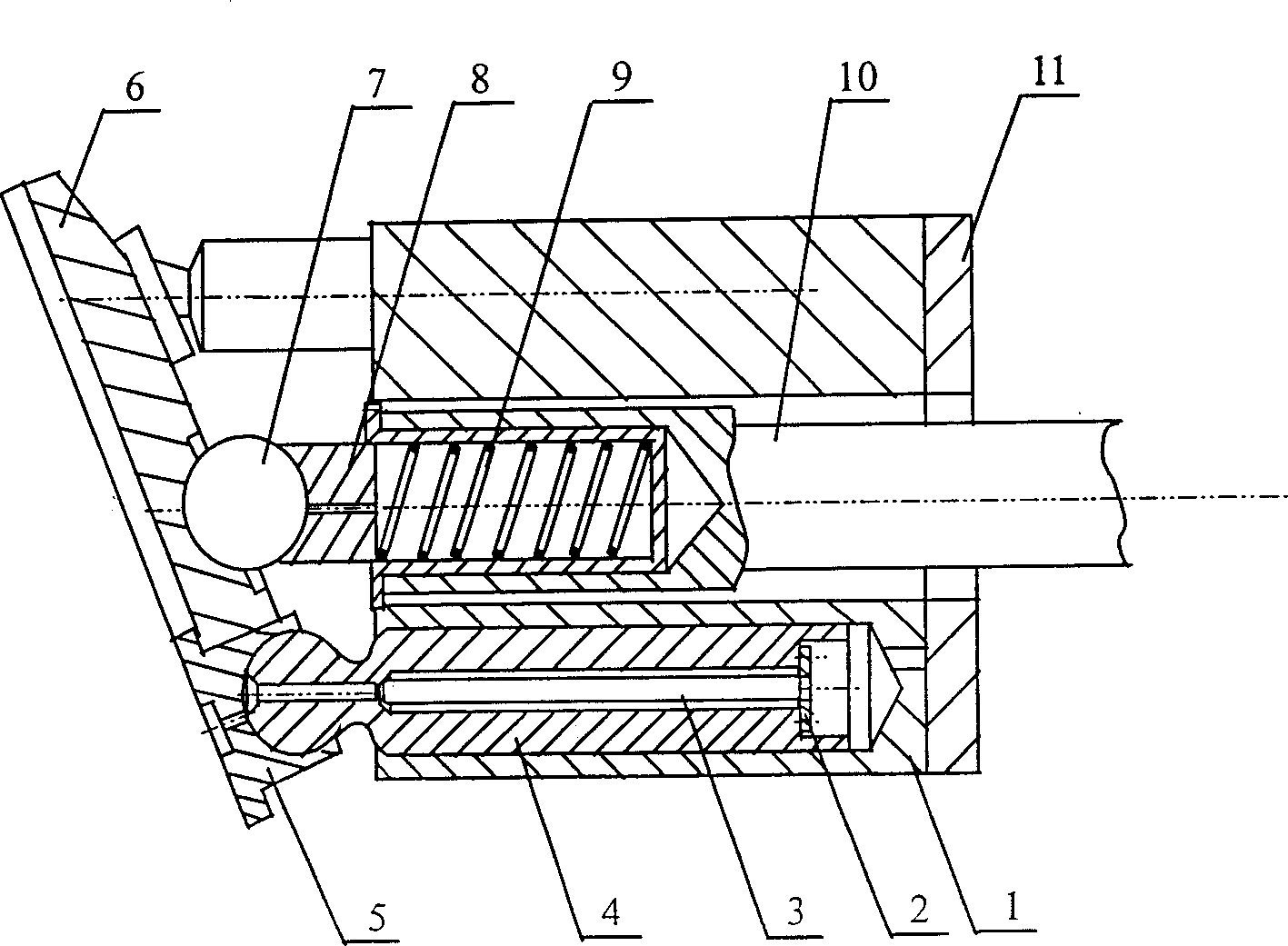

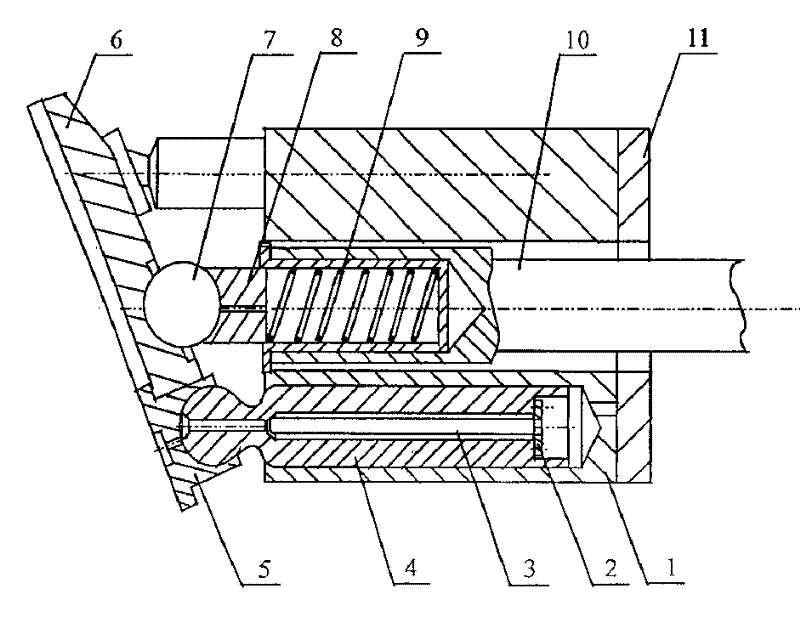

[0012] Such as figure 1 Shown is a schematic diagram of the structure of a low-noise hydraulic plunger pump with an accumulator. Including cylinder 1, flange 2, accumulator 3, plunger 4, sliding shoe 5, pressure plate 6, steel ball 7, inner sleeve 8, spring 9, main shaft 10, valve plate 11; accumulator 3 is installed on In the central small through hole of the plunger 4, a flange 2 with several small through holes in the axial direction is installed on the inner end surface of the large central hole of the plunger near the end of the valve plate.

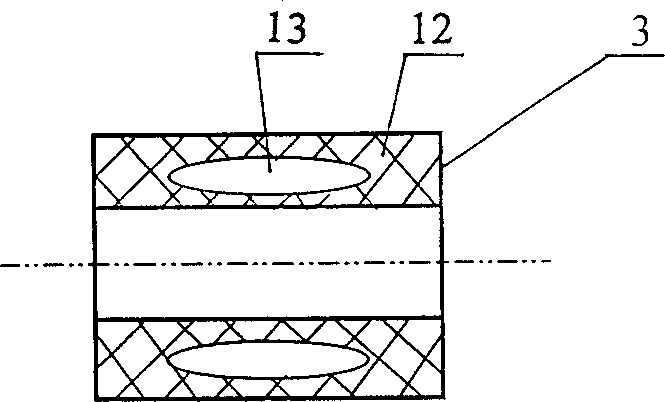

[0013] Such as figure 2 A schematic diagram of the structure of the accumulator is shown. The accumulator 3 is made of non-metallic material, and the non-metallic material 12 contains a little high-pressure gas 13 to play the role of energy storage and energy release.

[0014] When the plunger cavity transitions from the oil suction area to the oil discharge area, the plunger cavity filled with low-pressure oil suddenly connects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com