Connecting rod type rubber caterpillar

A rubber crawler and connecting rod technology, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of discontinuous runner tracks, poor cushioning, and walking vibration, and achieve improved walking stability without fatigue accumulation , the effect of preventing rubber cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

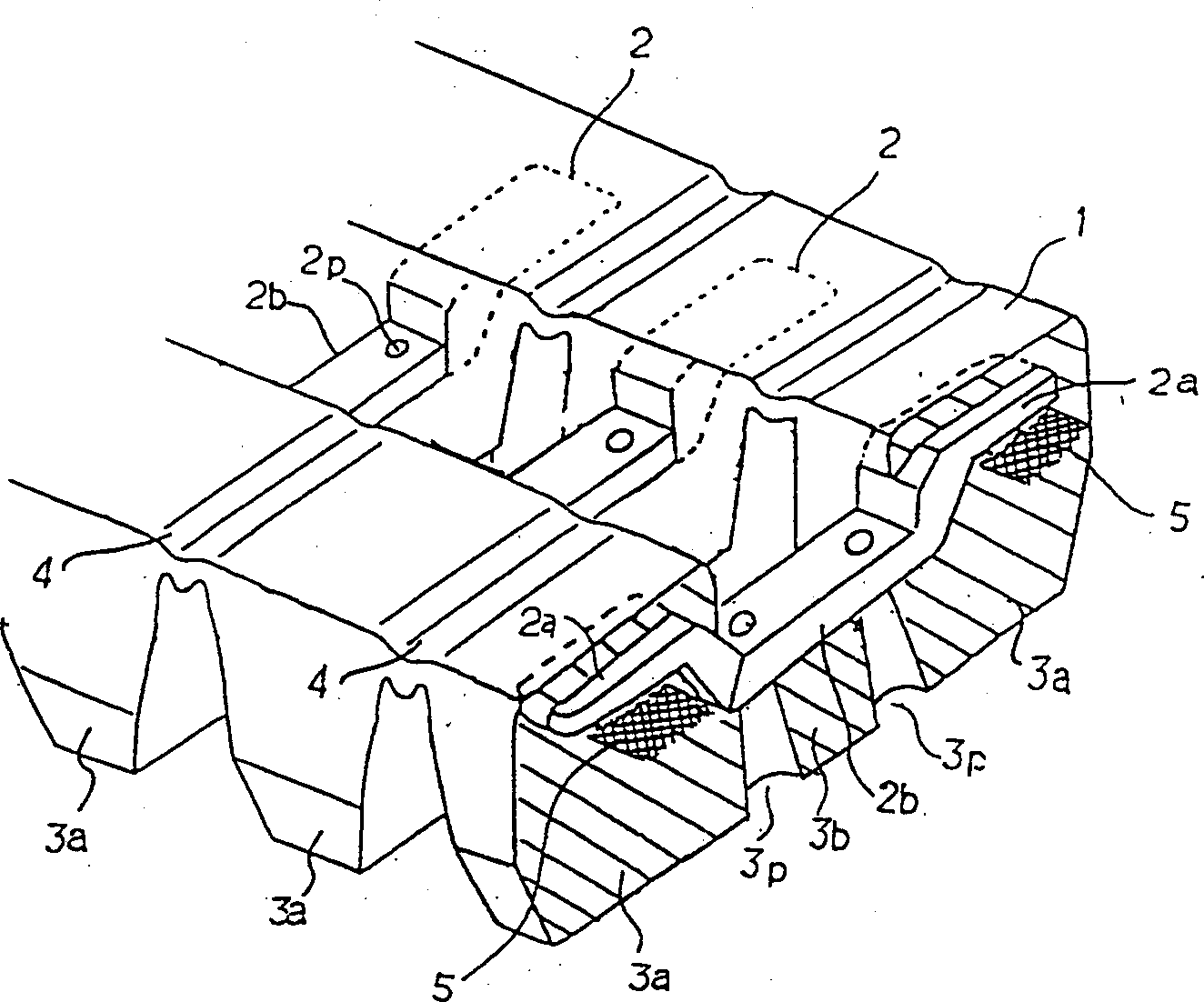

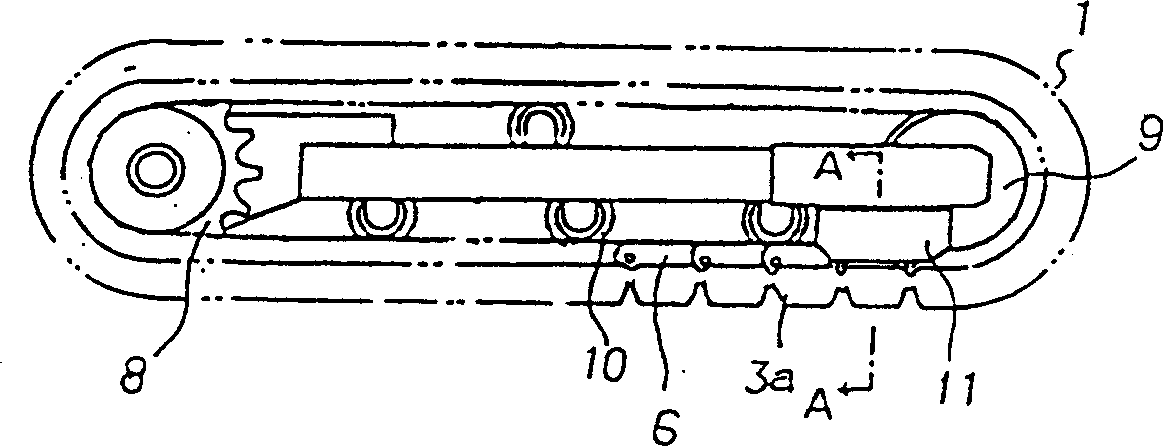

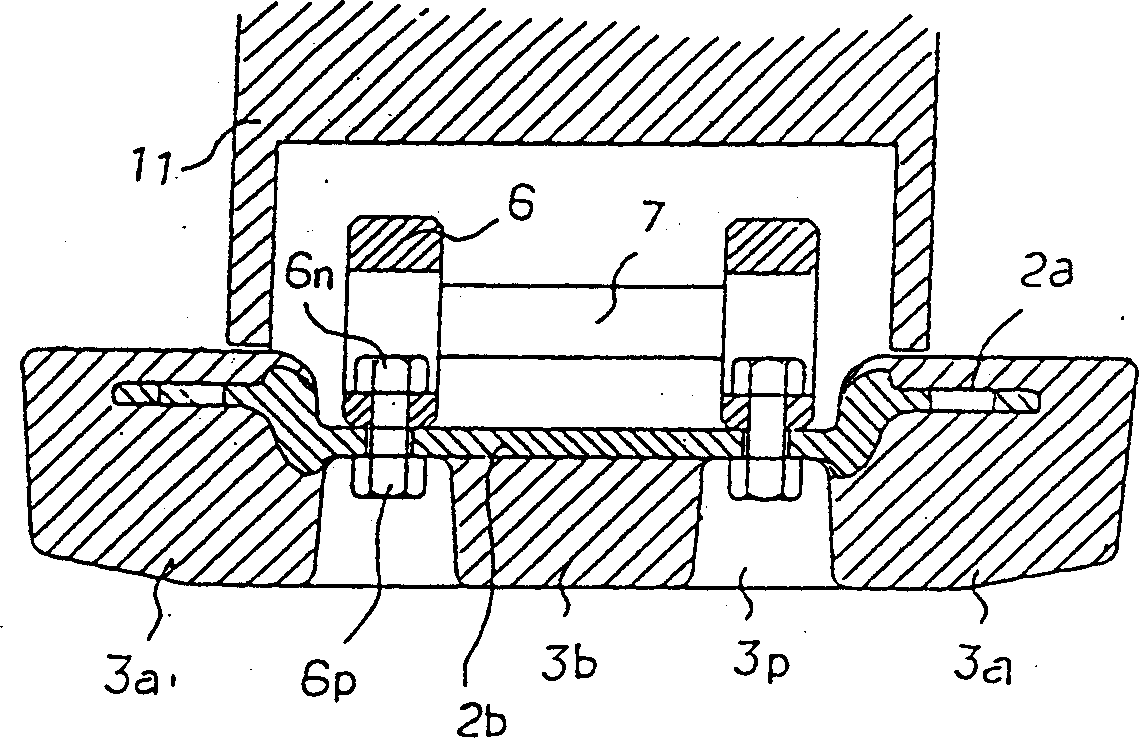

[0030] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 For representing the perspective view of the connecting rod type rubber track of the present invention, figure 2 In order to show the overall side view of the connecting rod type rubber crawler walking device installed, image 3 for along figure 2 The cross-sectional view of the width direction cut by the line A-A in Figure 4 for figure 2 Enlarged view of part of .

[0031] In the figure, 1 is a rubber crawler main body, and a mandrel 2 having wings 2a, 2a extending left and right and a concave central part 2b is buried in the rubber crawler main body 1 at predetermined intervals, and a central part 2b is formed on the central part 2b. The bolt hole 2p of the crawler link 6 is installed with a bolt 6p and a nut 6n. 3a is the wing protrusion corresponding to the mandrel wing 2a protruding toward the side where the rubber track contacts the ground, 3b is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com