Metal surface treatment method

A treatment method and technology for metal surfaces, applied in the direction of metal material coating process, etc., can solve problems such as accumulation of sodium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0063] (preparation example 1 prepares zinc nitrite aqueous solution)

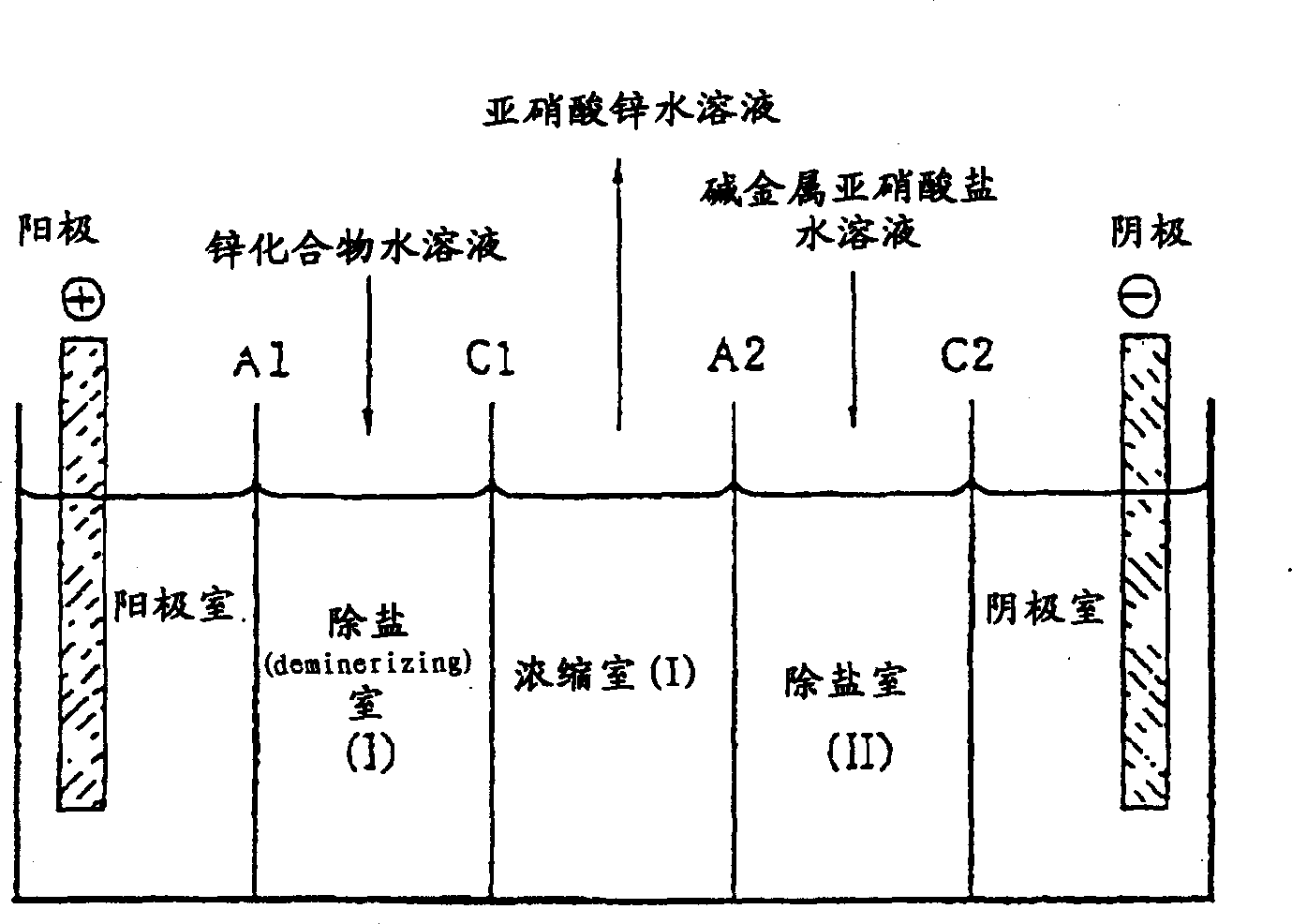

[0064] In the 5-compartment electrodialyzer using the ion-exchange membrane shown in Fig. 1, an anion-exchange membrane (product of Asahi Glass Co.; Selemion AMV) A1, a cation-exchange membrane (Asahi Glass Co. Co.'s product; Selemion CMV) C1, said anion exchange membrane A2 and said cation exchange membrane C2 to define an anode compartment, a desalination compartment (I), a concentration compartment (I), a desalination compartment (II) and a cathode compartment , and only make NO 2 and Zn ions selectively migrate through the anion-exchange membrane and cation-exchange membrane respectively to obtain an aqueous solution of zinc nitrite. The test protocol is as follows.

[0065] In this way, 575 g of zinc sulfate heptahydrate was dissolved in ion-exchanged water to prepare ZnSO with a concentration of 15%. 4 aqueous solution, which is fed into the desalination chamber (I). On the other hand, 600 g of s...

Embodiment 1

[0088] Example 1 Effect of sodium ion concentration in surface treatment bath In the surface treatment bath described above, the concentration of sodium ions was varied, and the results obtained with the following iron plates were evaluated. Iron sheet (size / type): 70mm×150mm / SPC (cold-rolled steel sheet) and GA (galvanized steel sheet) The results of SPC steel sheet are listed in Table 1, and the results of GA steel sheet are listed in Table 2.

[0089] Table 1

[0090] sodium concentration

3600ppm

5000ppm

7500ppm

10000ppm

Appearance, naked eye observation

it is good

it is good

it is good

Difference

Coating weight

2.12

2.37

2.28

2.72

Crystal size

uniform, good

uniform, good

uniform, good

uneven, large

[0091] Table 2

[0092] sodium concentration

reference example 1

[0093] Reference example 1 Determine Na ion-1 (NaNO 2 Aqueous solution) cumulative amount

[0094] The SPC substrate (70mm×150mm) was treated under the above conditions to supplement the components (phosphoric acid, zinc, etc.) consumed during coating formation.

[0095] Quantities of various liquids on conventional production lines

[0096] A: Capacity of chemical conversion tank: 120 tons

[0097] B: NaNO used 2 Aqueous solution (NO 2 The concentration of sodium ions is 27% by weight, and the concentration of sodium ions is 13% by weight) Quantity: 150mL / batch

[0098] C: Amount of zinc used / batch: 60g

[0099] D: Amount of chemical conversion bath carried / batch: 5L (amount carried / substrate: 2mL; 2500 treated plates)

[0100] The above steps were repeated 3 times (3 cycles) as 1 cycle, and a total of 7500 plates were processed. When the carrier liquid of the above-mentioned chemical conversion bath is not recovered, NaNO 2 NO in aqueous solution 2 The ion concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Free acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap