Luminous display and its making method

A technology of light-emitting display and electrode device, which is applied in the direction of display device, lighting device, cold cathode manufacturing, etc., can solve the problems of multiple partition parts, limitation of shape and image outline, increase of material and device manufacturing cost, and cost of excess gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

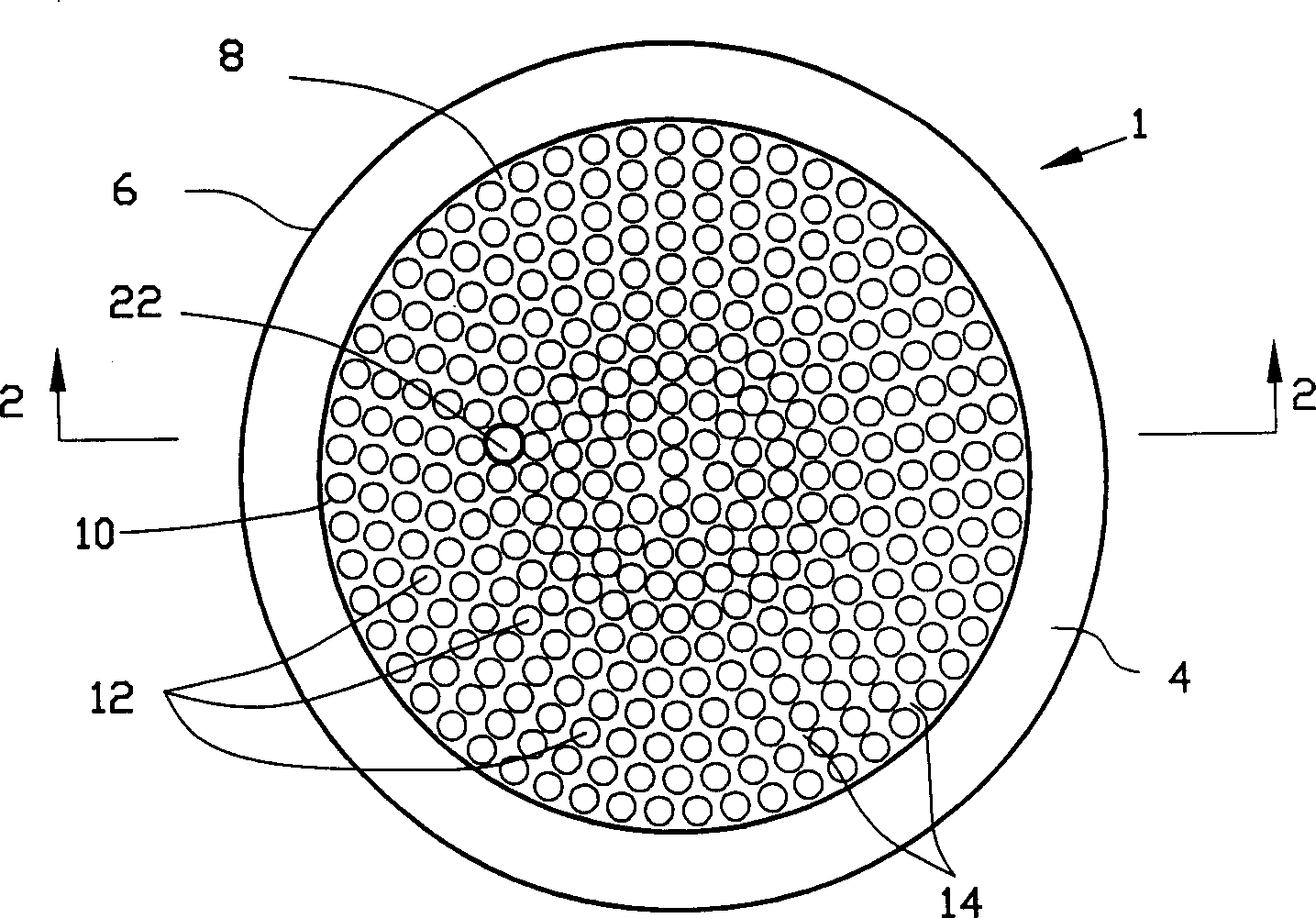

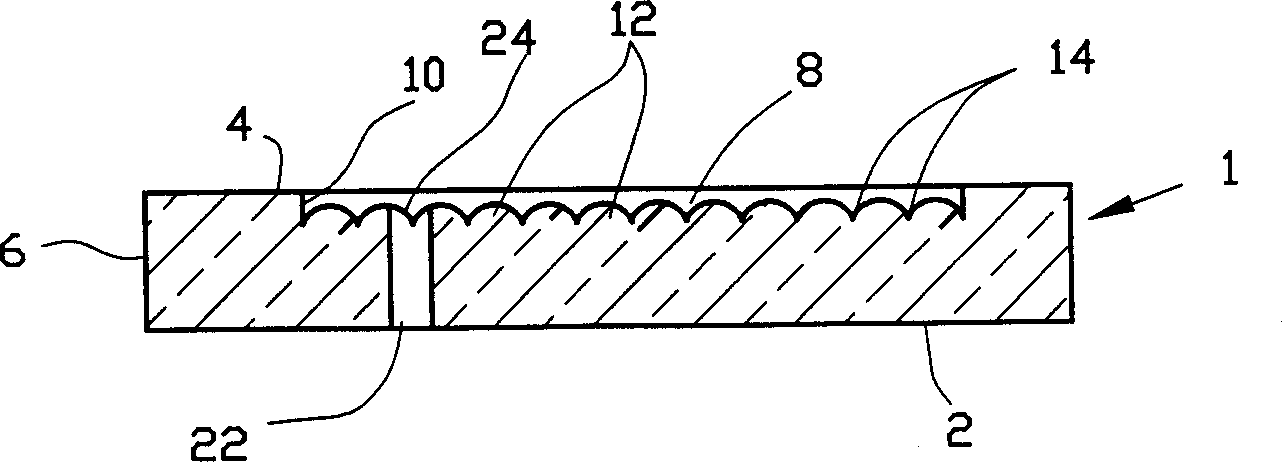

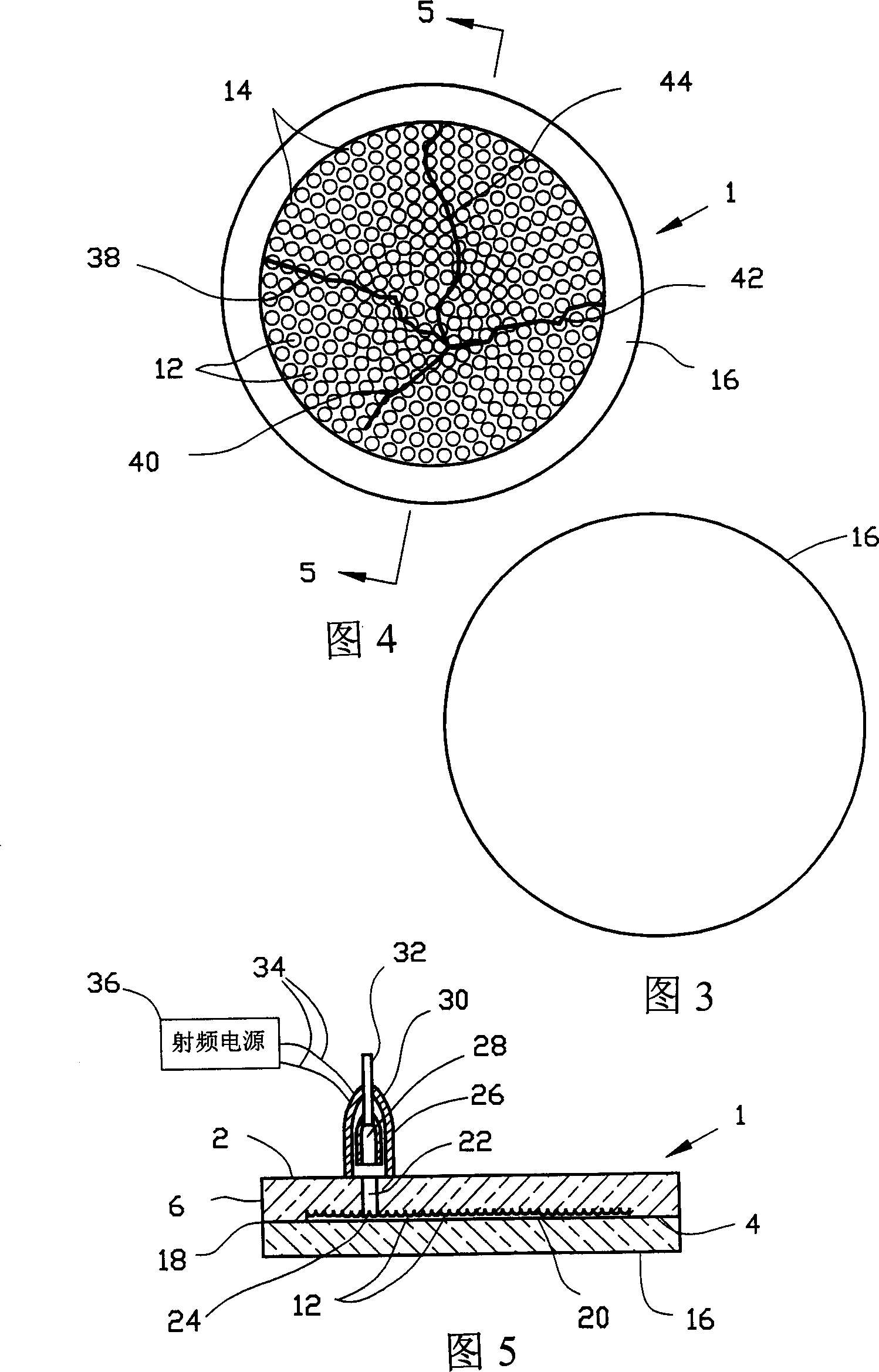

[0026] Such as figure 1 As shown in -5, in the first embodiment of the present invention, the rear glass 1 is preferably molded into a circular body with a suitable mold (not shown), for example, about 300 mm in diameter, and has a rear surface 2, A front surface 4 and an outer peripheral surface 6. A circular recess or cavity 8 is formed in the front surface 4 and has a peripheral radial outer surface 10 extending into the depth or bottom of the cavity. A number of almost semicircular elements or projections 12 extend upwardly from the bottom of the cavity, as figure 2 As shown, the height is lower than that of the peripheral surface 10, the reason for which will be further clarified later in the description. This configuration provides intersticial channels 14 between adjacent elements 12 of the array of elements 12, as figure 1 The array of elements 12 covers the bottom of cavity 8 as shown. Elements 12 may be tapered, conical, or prismatic to provide interstitial chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com