Ceramic parquet board and its production process

A manufacturing process and patterned board technology, which is applied in the field of ceramic products and their manufacturing processes, can solve the problems of small bonding surface, easy injury to users, separation of parquet boards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

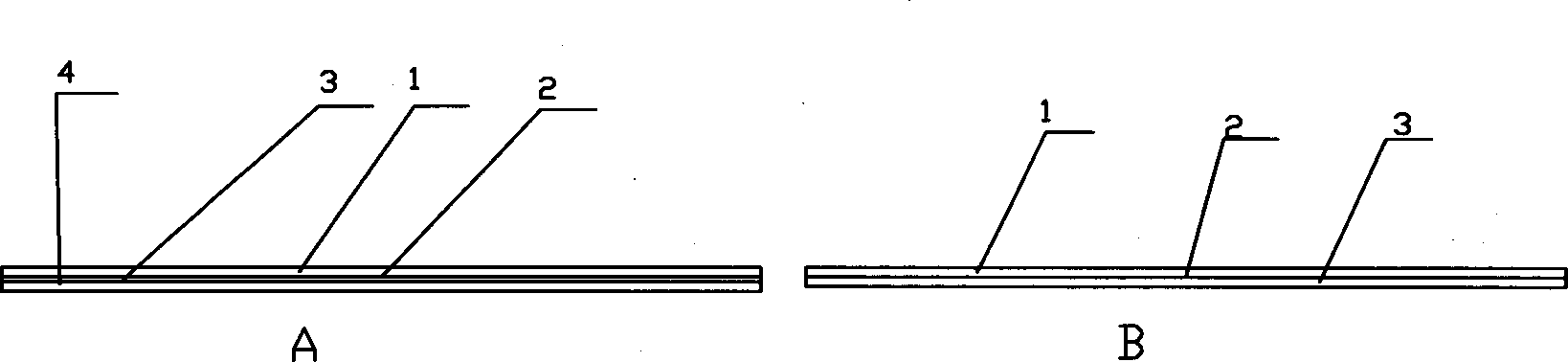

[0011] The manufacturing process of the novel ceramic mosaic board of the present invention is achieved in this way, including the manufacture of the mosaic components and the splicing of the mosaic components. The supporting board can be ceramic tiles, plastic plates, or wood, and then the surface of the ceramic mosaic board with the supporting layer is polished to make the polished ceramic mosaic board smooth. Such as figure 1 As shown in A, the new ceramic mosaic board produced includes a mosaic board surface 1, and its special feature is that a supporting plate 4 is fixed on the bottom surface 2 of the mosaic board surface 1 through an adhesive 3, and the supporting plate can be Ceramic tiles can also be plastic sheets or wood, and the surface of the mosaic board is polished to a smooth and flat shape.

Embodiment 2

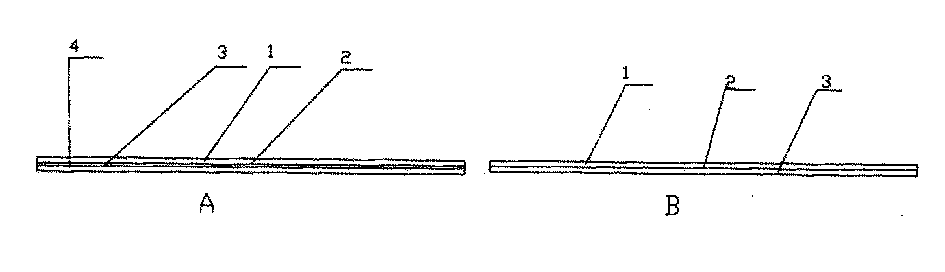

[0013] The manufacturing process of the novel ceramic parquet board of the present invention is to use a hard resin or a polymer composite material bonding layer as a supporting layer on the basis of Embodiment 1. The supporting layer can be a glass fiber reinforced plastic layer, and the process of bonding the glass fiber reinforced plastic layer is In this way, the polymer adhesive layer is first coated on the bottom surface of the spliced mosaic board surface, and then the glass fiber is laid on the adhesive layer. The polymer adhesive layer can be an epoxy resin composite adhesive layer, or It can be a polyamide resin composite adhesive layer or a polyester composite adhesive layer, and the glass fiber can be replaced by carbon fiber or chemical fiber. Such as figure 1 As shown in B, the new ceramic mosaic board made includes a mosaic board surface 1, which is special in that a glass fiber reinforced plastic layer 3 is fixed on the bottom surface 2 of the mosaic board su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com