Acoustic device for track

A technology for sound-absorbing devices and rails, which is applied in the direction of rails, noise-absorbing devices, roads, etc., can solve problems such as difficulties, and achieve the effects of increasing maintainability and durability, reducing noise, and high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

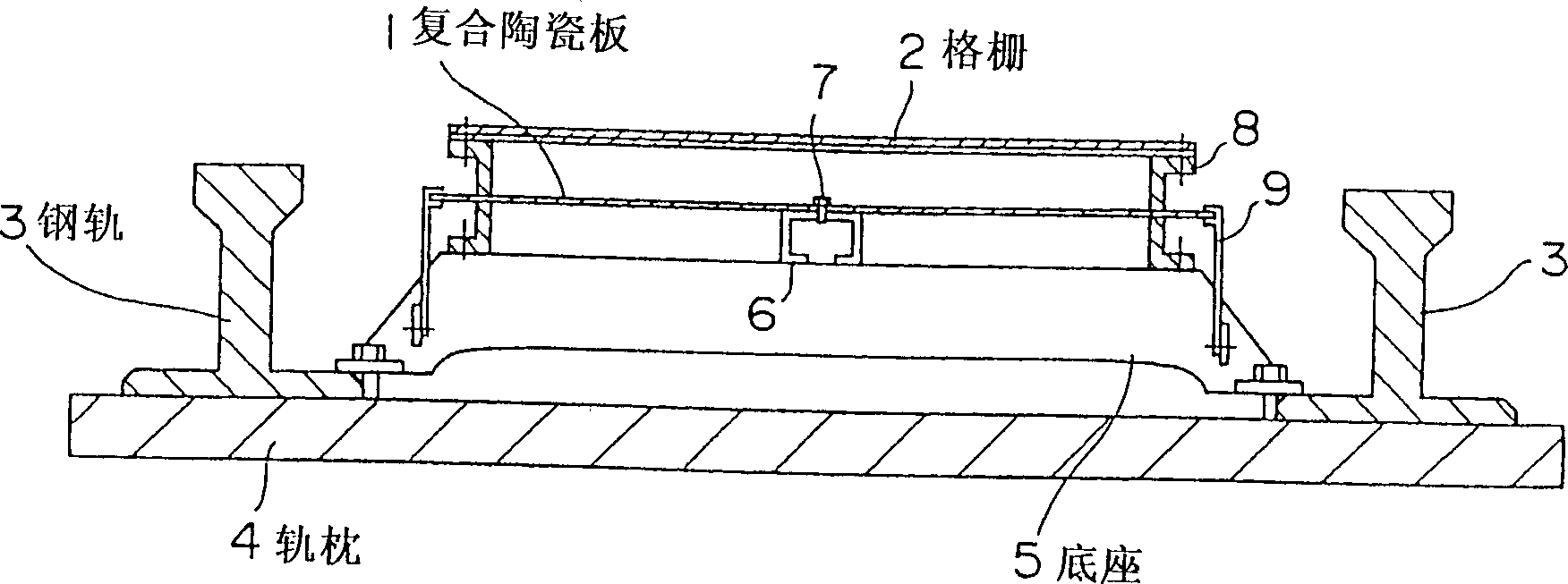

[0023] figure 1 is a side view of a sound absorbing device for rails according to one embodiment. A composite ceramic sound-absorbing panel is used as the sound-absorbing panel in which an aluminum-based ceramic material and an aluminum expanded metal are bonded to each other.

[0024] This embodiment provides a sound-absorbing device, in which a grid 2 is processed, and the thickness of the air layer between the base 5 and the composite ceramic sound-absorbing panel 1 can be controlled. A composite ceramic sound-absorbing panel 1 is installed between the two rails 3 and is supported by a support member 9 and a C-shaped channel steel 6 . The support 9 and the C-shaped channel steel 6 are supported by the base 5 machined below these elements, while the base 5 itself is fixed by different means. For example, the base 5 can be fixed to the sleeper 4 by screwing in nails, or it can also be fixed in the concrete state by anchors in the holes. Of course, it can also be figure 1 ...

no. 2 example

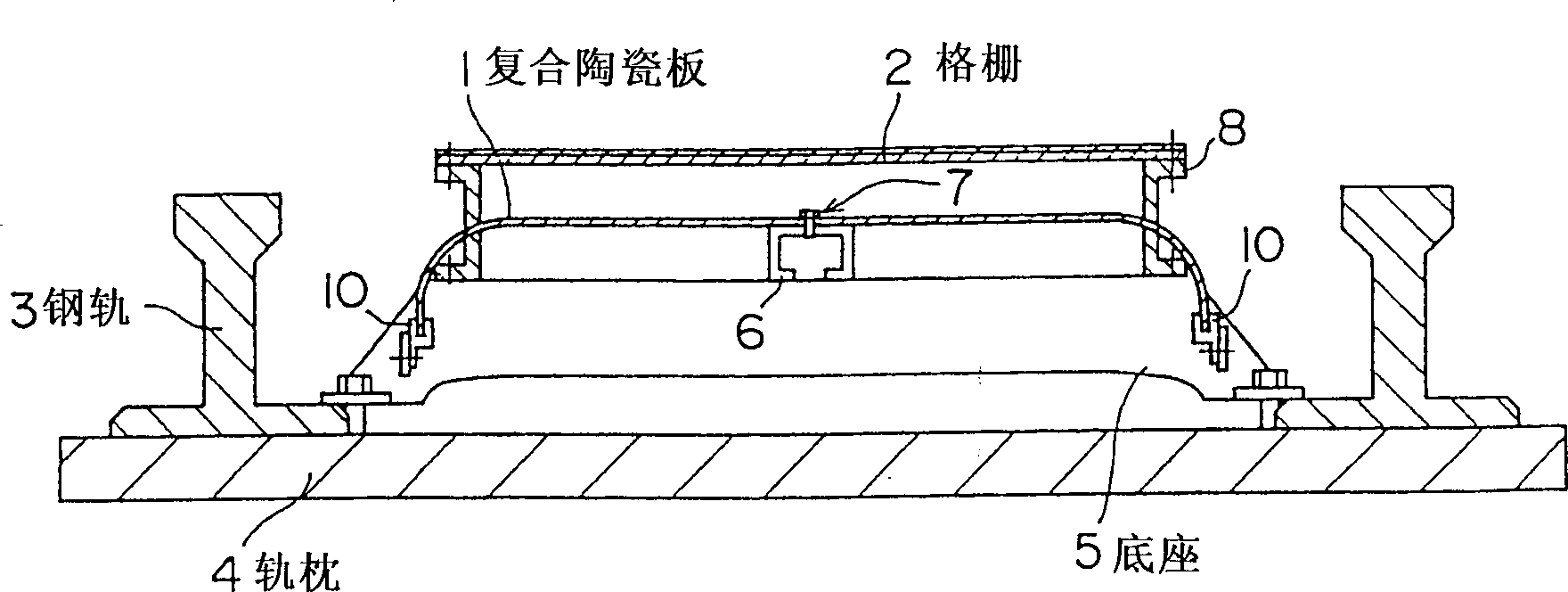

[0030] figure 2 is a sectional view of the sound absorbing device for rails according to the second embodiment. In addition to the structure shown in the first embodiment, this embodiment provides a sound-absorbing device in which both ends of the composite ceramic sound-absorbing panel 1 near the two steel rails 3 are bent at approximately 90 degrees until they are aligned with the The top surfaces of the two rails are perpendicular, thereby forming a curved portion. Since the composite ceramic sound-absorbing panel 1 adopted in the present invention has proper elasticity, it can be bent and used. In this embodiment, by utilizing most of the above-mentioned characteristics of the panel 1 , the composite ceramic sound-absorbing panel 1 is supported by the sound-absorbing panel support 10 , while the middle part of the panel 1 is fixed by the C-shaped channel steel 6 and the bolt 7 .

[0031] The composite ceramic sound-absorbing panel 1 has different sound-absorbing effects...

no. 3 example

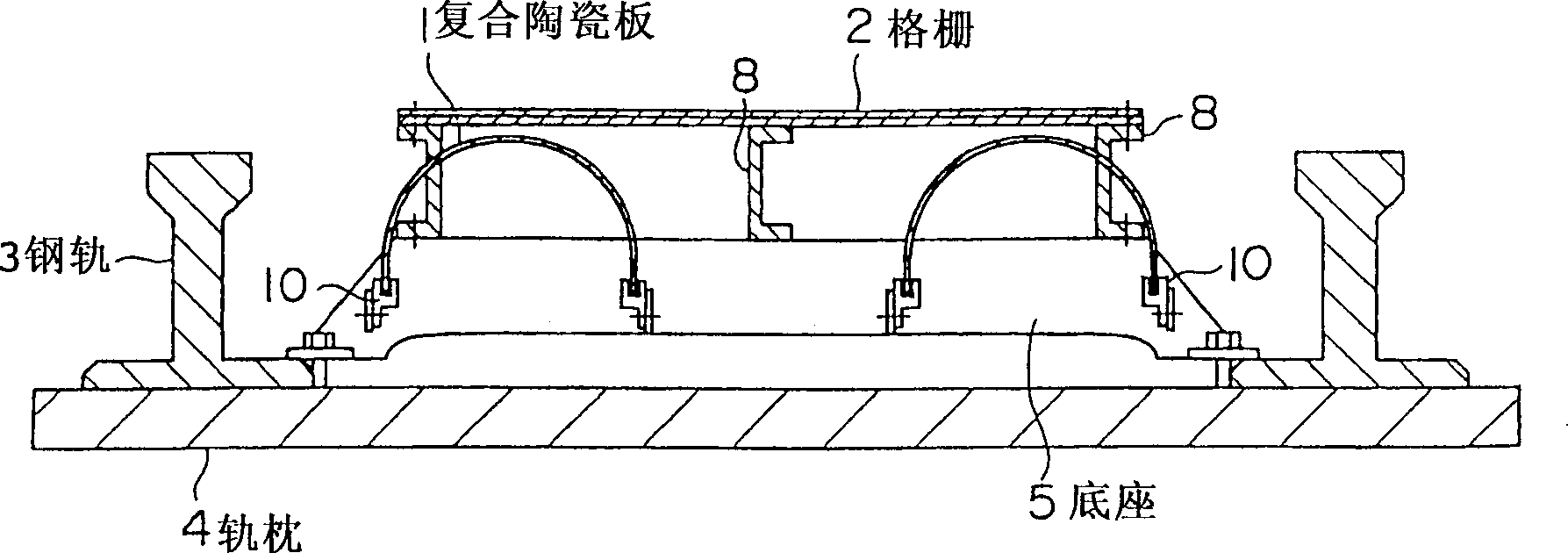

[0033] image 3 is a sectional view of the sound absorbing device for rails according to the third embodiment. In addition to the structure shown in the first embodiment, this embodiment provides a sound absorbing device in which two composite ceramic sound absorbing panels 1 are arranged in parallel so as to be perpendicular to the echo from the bottom of the vehicle. Specifically, in this sound-absorbing device, the two ends of each of the two composite ceramic sound-absorbing panels installed close to each of the two steel rails 3 are bent at approximately 90 degrees until they are aligned with the rails. The top surface is perpendicular to have a curved portion.

[0034] In this embodiment, the two ends of each composite ceramic sound-absorbing panel 1 are fixed by the sound-absorbing panel support 10, and the middle part thereof is not supported. Therefore, each acoustic panel has a bow shape across its entire width. Although in this embodiment two composite ceramic so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com