Support disc base unit for supporting end open spinning rotor

A technology of spinning at the beginning and supporting discs, which is applied in the field of supporting disc bases, can solve problems such as unbalanced and inaccurate supporting discs, achieve the effects of improving adhesion, improving contact area, and reducing development costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

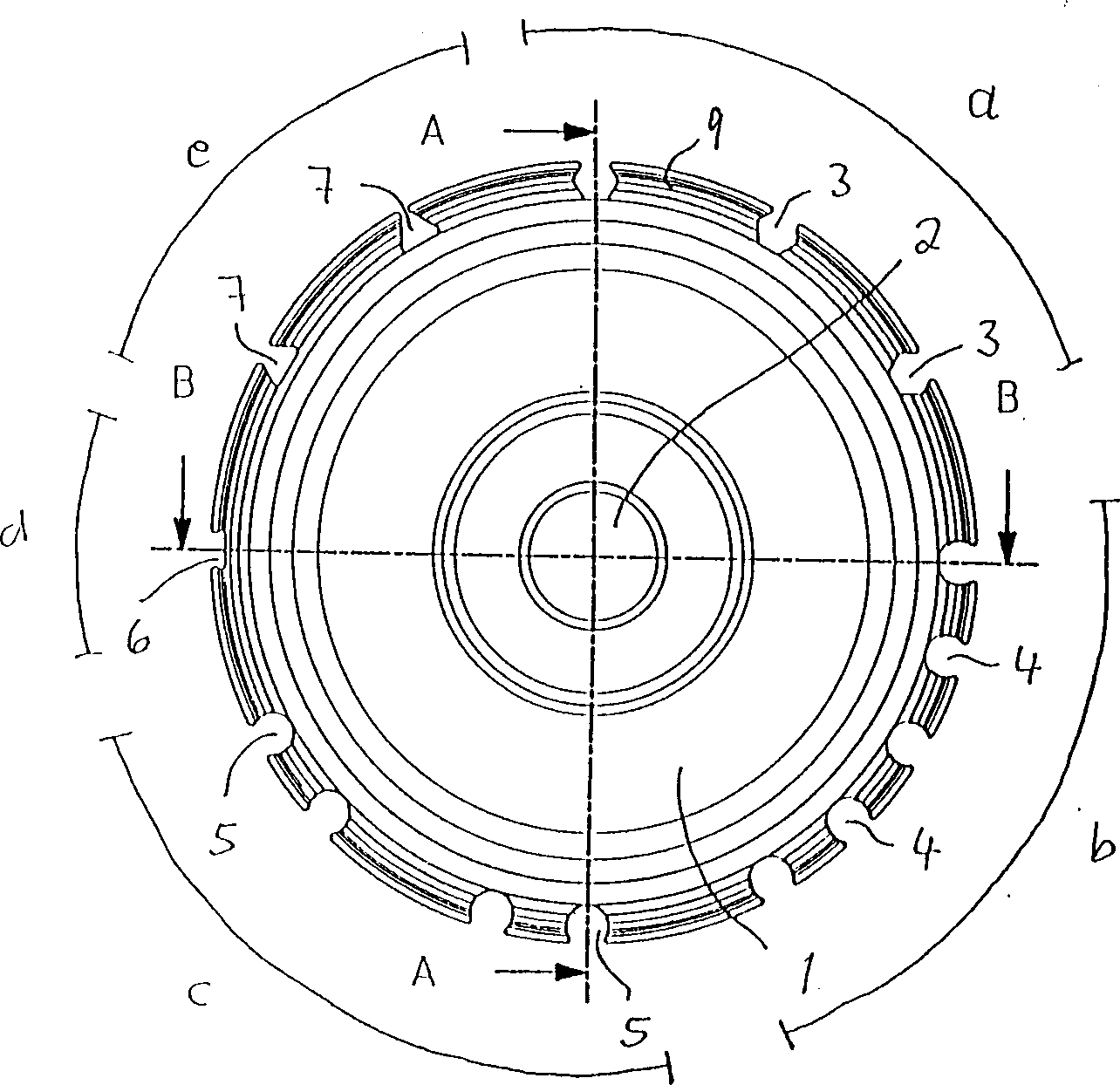

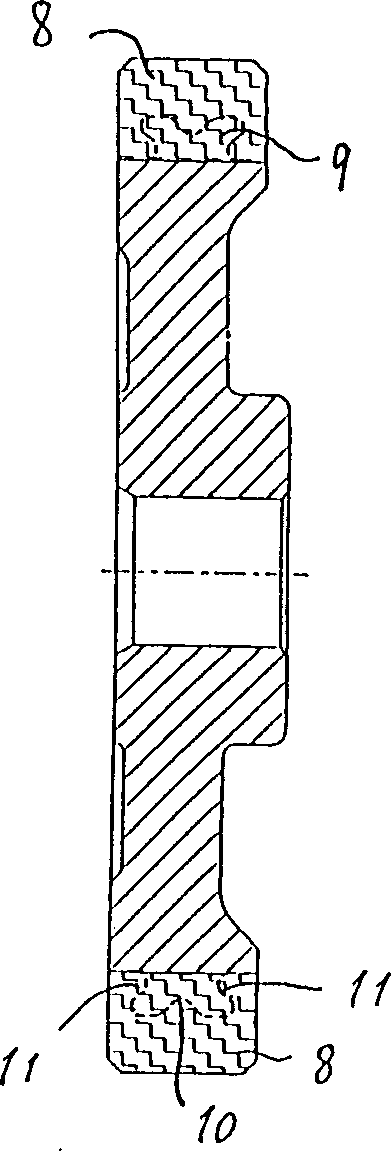

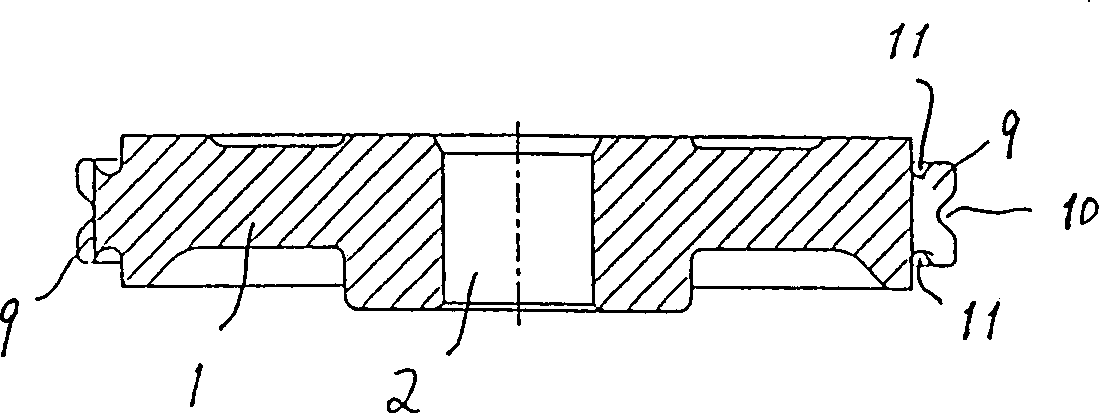

[0050] Figure 1A is a side view of the support disk base 1 . Its inner area forms a hub shape, while the base body 1 with the hole 2 can be pushed or pressed onto the shaft. Grooves 3 , 4 , 5 , 6 , 7 are formed in the axial direction on the outer circumference of the base body 1 . The grooves 3 , 4 , 5 , 6 , 7 shown on the base body 1 represent the actual axial grooves of various embodiments as best examples here, these grooves have different cross-sectional shapes and in the circumferential direction There are different spacings. like in Figure 1B Shown in section, a support ring 8 is mounted on the outer circumference of the base body 1, after which the shaft of the spinning rotor of the spinning machine is spread out in a known manner.

[0051] exist Figure 1A Among them, the outer circumferential section of the base body 1 indicated by a is provided with an axial groove 3 with a hexagonal cross section. The sides of the hexagon are open towards the outer circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com