Valve assembly of reciprocating compressor

A compressor and valve assembly technology, which is applied to engine components, variable displacement pump components, liquid variable displacement machinery, etc., can solve the problem of increased noise, reduced compression efficiency of compressors, and fracture of reed valve 61 and stopper 71 and other problems to achieve the effect of preventing leakage and improving compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

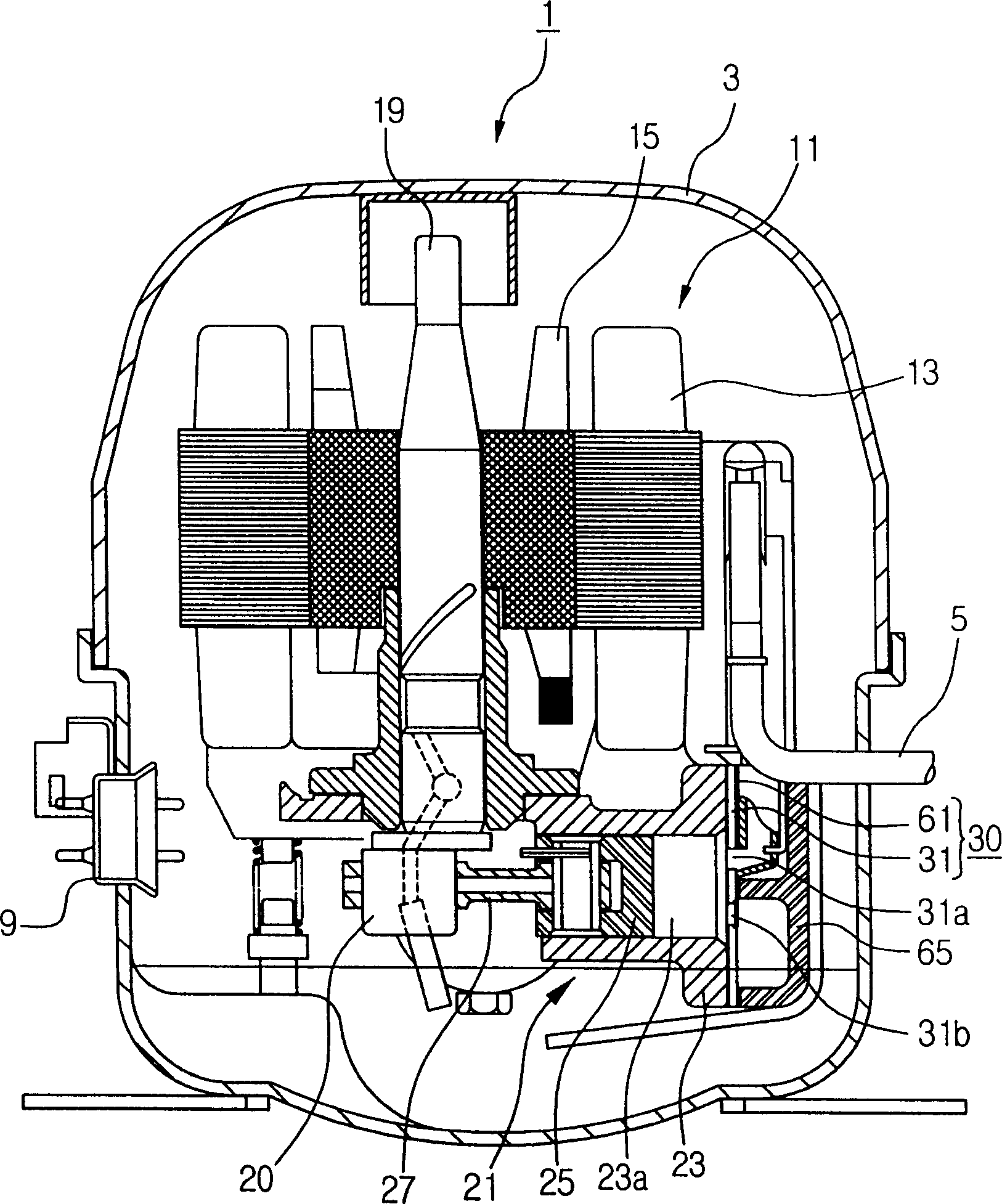

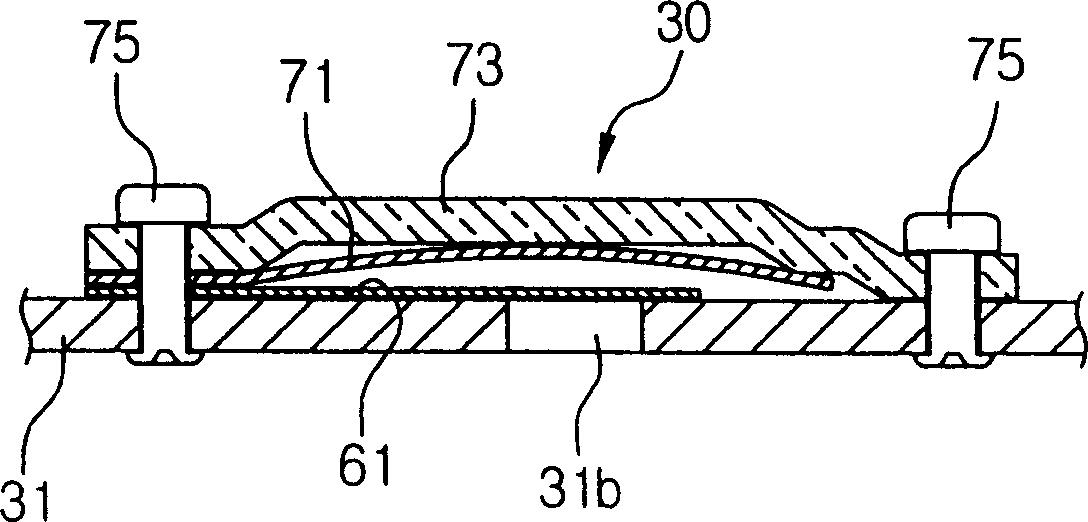

[0023] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. Throughout this specification, for figure 1 Components that are the same as those of the conventional compressor will be given the same reference numerals, and descriptions thereof will be omitted.

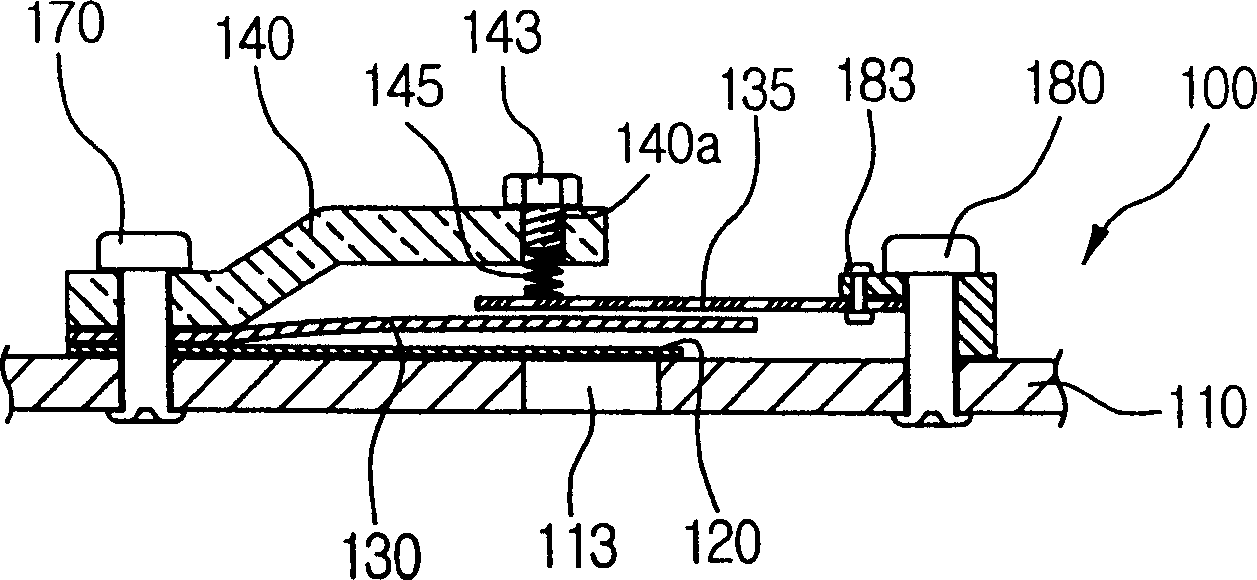

[0024] image 3 is an enlarged cross-sectional view of a valve assembly according to the present invention. The valve assembly 100 according to the present invention includes: a valve plate 110 with a suction hole (not shown) and a discharge hole 113; a positioning member 140 fixed on the valve plate 110 by a fastening bolt 170; The reed valve 120 between the pieces 140; and the first and second stoppers 130 and 135 for resisting the deformation force of the reed valve 120.

[0025] The reed valve 120 opens and closes the discharge hole 113 . During the movement of the piston 25 from the top dead center to the bottom dead center, the cylinder device 21 suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com