Preparation of dihydroxy-benzene

A technology for dihydroxybenzene and diisopropylbenzene oxidation, which is applied in the field of preparation of dihydroxybenzene and can solve problems such as insufficient purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

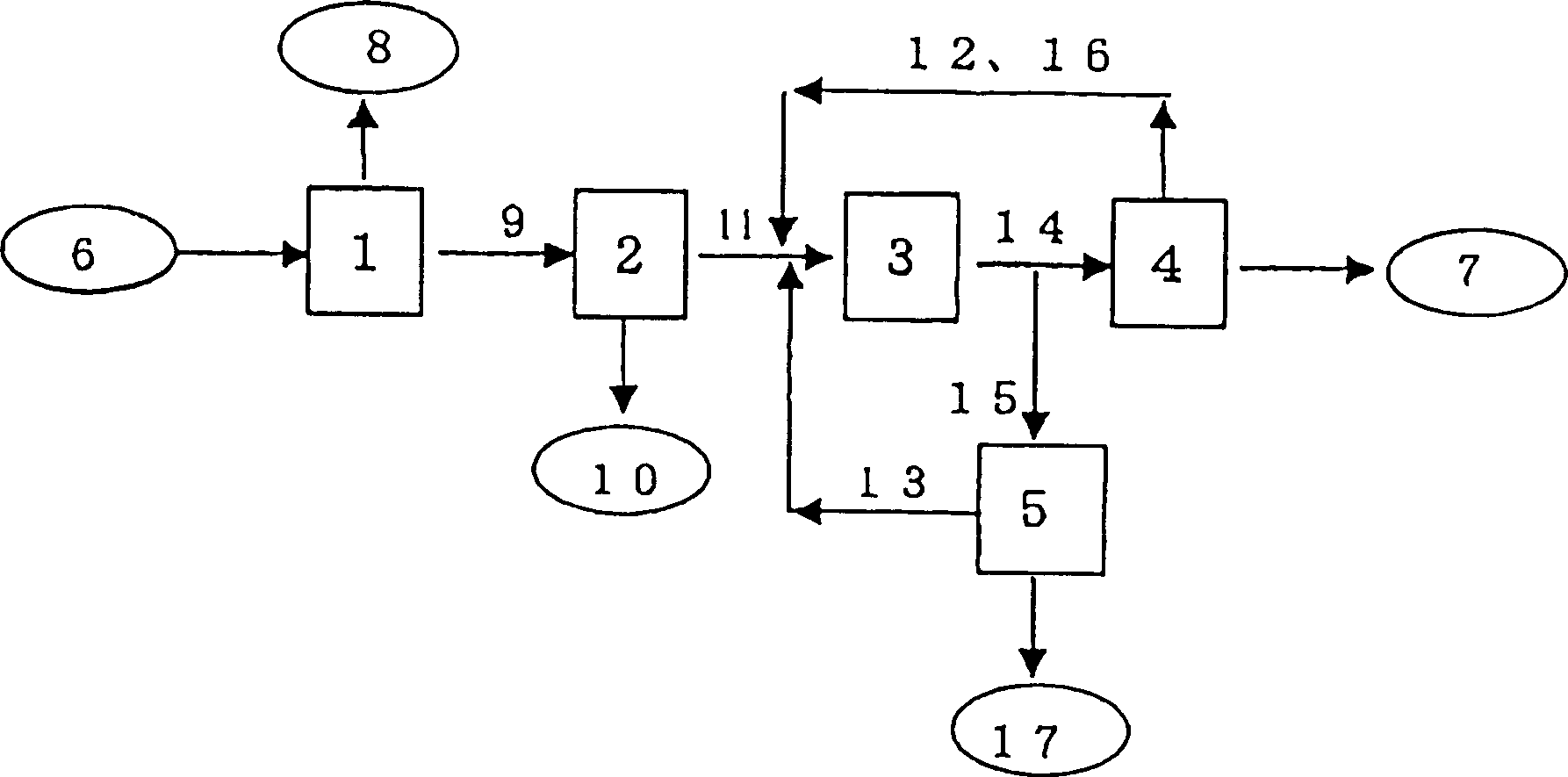

Method used

Image

Examples

Embodiment Embodiment 1

[0023] The m-diisopropylbenzene is oxidized to obtain a reaction mixture containing m-bis(2-hydroperoxy-2-propyl)benzene (step (1)); the m-di(2-hydroperoxy) in the reaction mixture is decomposed Oxy-2-propyl)benzene to obtain a mixture containing crude resorcinol (step 2). It was determined that the mixture containing crude resorcinol contained 10% by weight of resorcinol, 10% by weight of acetone, 0.5% by weight of m-isopropenylphenol, and 70% by weight of methyl isobutyl ketone.

[0024] Using a distillation column, under the condition of -91-0KpaG, distilling 23 parts by weight of the mixture containing crude resorcinol to obtain 20 parts by weight of a fraction containing 11% by weight of acetone from the low boiling point portion, And 2.5 parts by weight of the fraction from the high boiling point portion containing 92% by weight of resorcinol, 1-5% by weight of m-isopropenylphenol, and 6% by weight of a heavy substance (step (3)).

[0025] Using a rectification tower, under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com