In-line measuring-controlling device for water content in mixing moulding sand and its operating method

A measurement and control device, moisture technology, applied in the field of casting sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

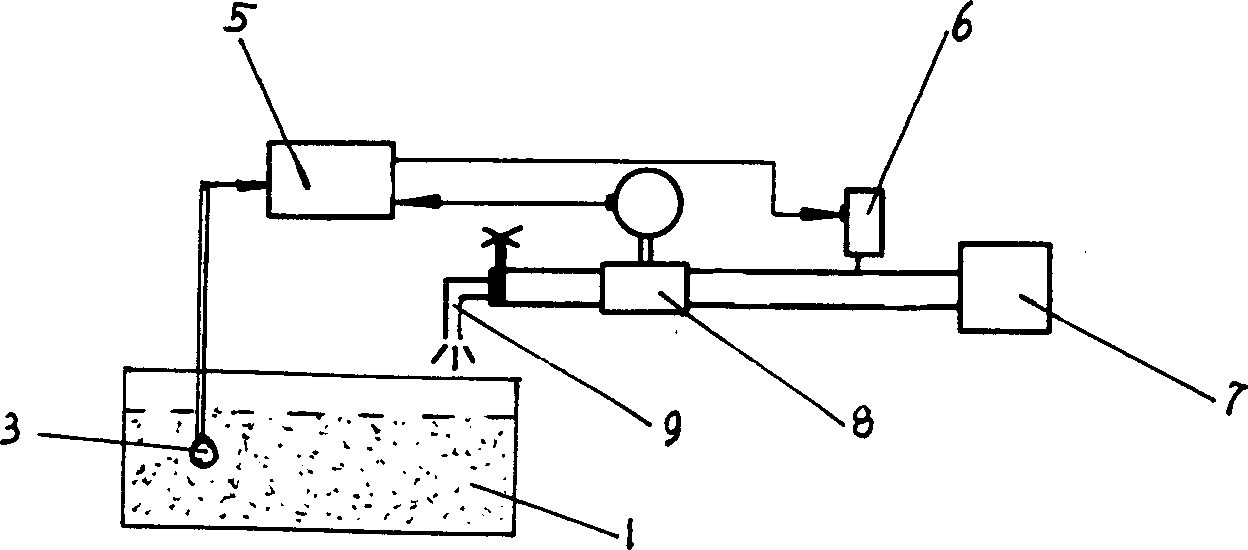

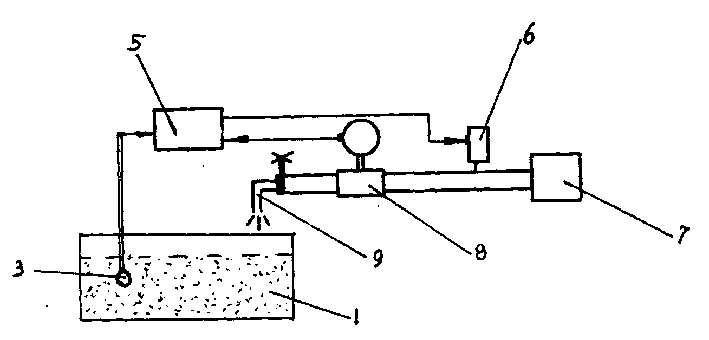

[0019] see figure 1 , figure 1 It is a structural block diagram of Embodiment 1 of the moisture on-line measurement and control device for the molding sand mixing process of the present invention. With a special structure, an external bracket can be used to fix the moisture sensor 3 in the sand mixer 1. After the sand mixer 1 is running, a relative movement is formed between the moisture sensor 3 and the chassis of the sand mixer, and the lead wire of the moisture sensor 3 There will be no problem of entanglement. Depend on figure 1 Visible, the present invention has the simplest structure, is made of electromagnetic valve 6 and water flowmeter 8, computer 5 installed on the pipeline 9 of moisture sensor 3, water source 7 in sand mixer 1, and said computer 5 also can be used single-chip microcomputer to replace.

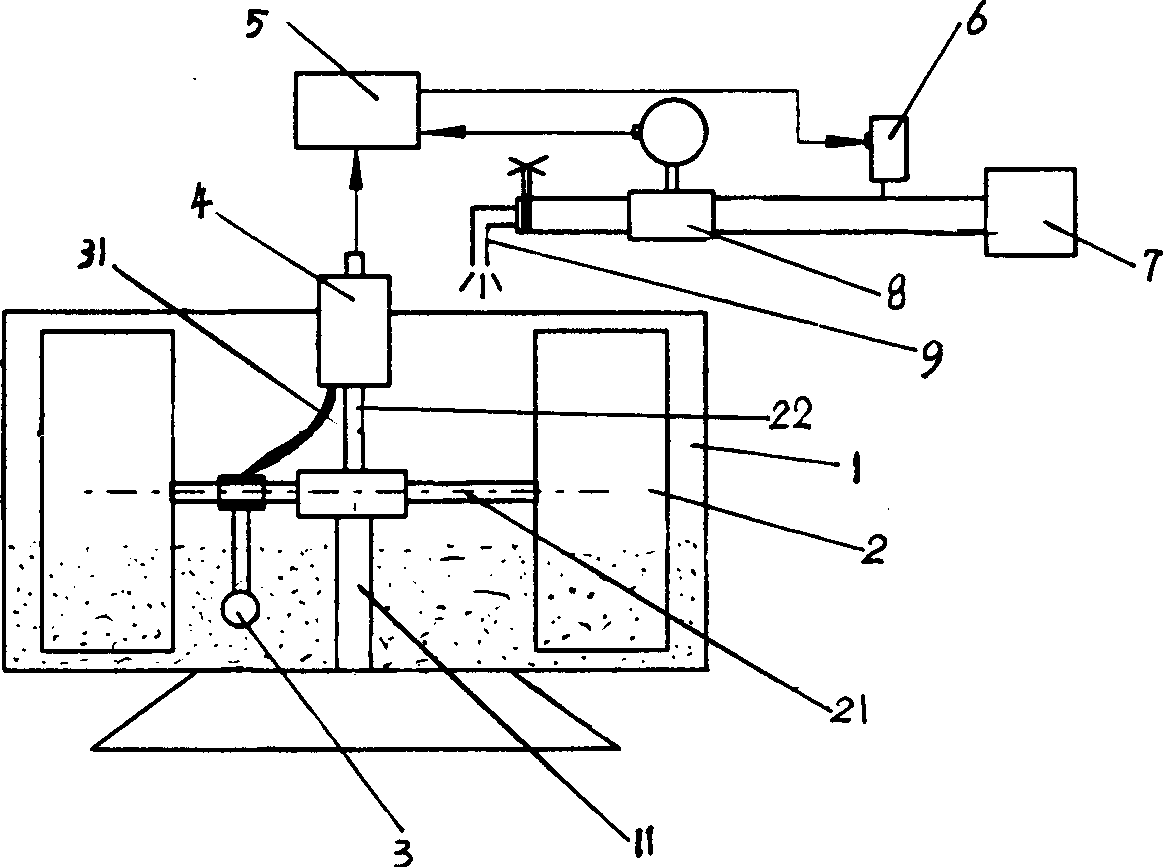

[0020] figure 2 It is a structural block diagram of Embodiment 2 of the present invention, which is designed to solve the problem that the installation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com