Switch over improving method between power source and frequency converter

A frequency converter, variable technology, applied in the direction of electrical components, transportation and packaging, AC motor control, etc., to achieve the effect of smooth transition and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

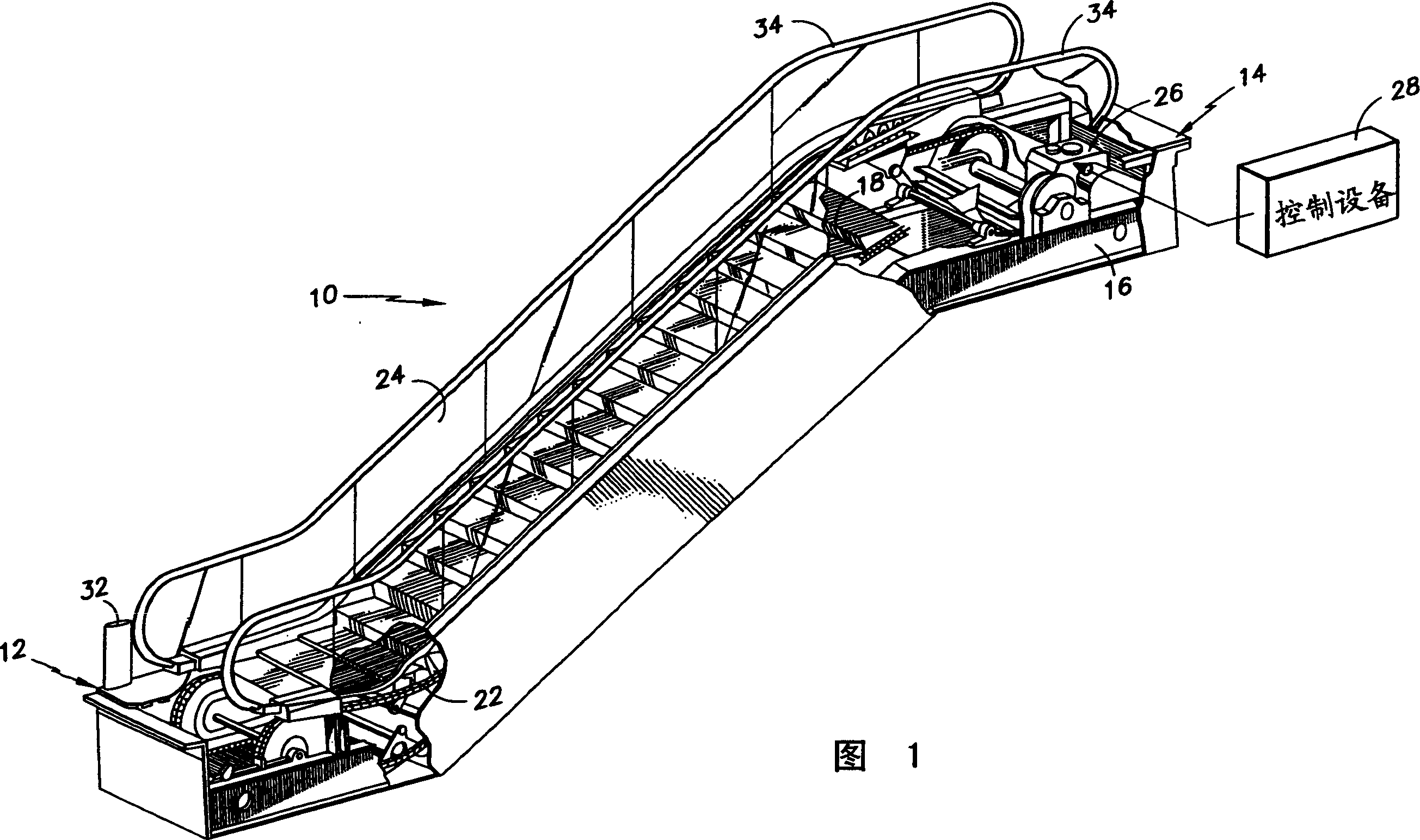

[0030] An escalator, shown in partial section and in perspective view in Figure 1, will be described as an example of a conveyor system according to the present invention.

[0031] As shown in Figure 1, the escalator 10 comprises a landing 12, an upper landing 14, a support frame 16, many step plates 18 which are connected successively to form a continuous band, a dragging device for driving the step plates 18. Dynamic chain 22, a pair of railings 24 extending on both sides of the connected step plate 18, a driving motor 26 coupled with the drag zipper 22 in the form of a driving device, a control that acts simultaneously with the driving motor 26 Device 28, and a device 32 for signaling the need to deliver in the form of a passenger sensor, which may be, for example, an on / off photocell control device but may also consist of a step mat, or a hand switch, or a foot switch . The step plate 18 forms a platform for conveying passengers between the two landings 12 and 14 . Each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com