Method for eliminating smoke speed deviation of horizontal flue of corner-fired boiler by using warped separation screen

A technology of boiler horizontal flue and four-corner injection combustion, which is applied in the direction of combustion method, combustion product treatment, exhaust gas device, etc., and can solve problems that have not been solved

Inactive Publication Date: 2003-02-05

SHANGHAI UNIVERSITY OF ELECTRIC POWER

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the thermal deviation of the gas flow in the horizontal flue of the furnace outlet caused by the residual rotation of the furnace has not been solved in the engineering field

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

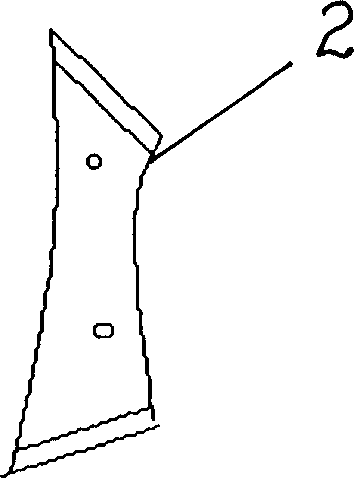

[0019] Twist a rectangular plate with a length of 1070mm, a width of 20mm, and a thickness of 4mm according to the above method, and after twisting, the two short sides are 45°. The partition screen is hung at the furnace outlet of the boiler, and compared with the partition screen without distortion, the speed deviation of the horizontal flue is reduced by about 50%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

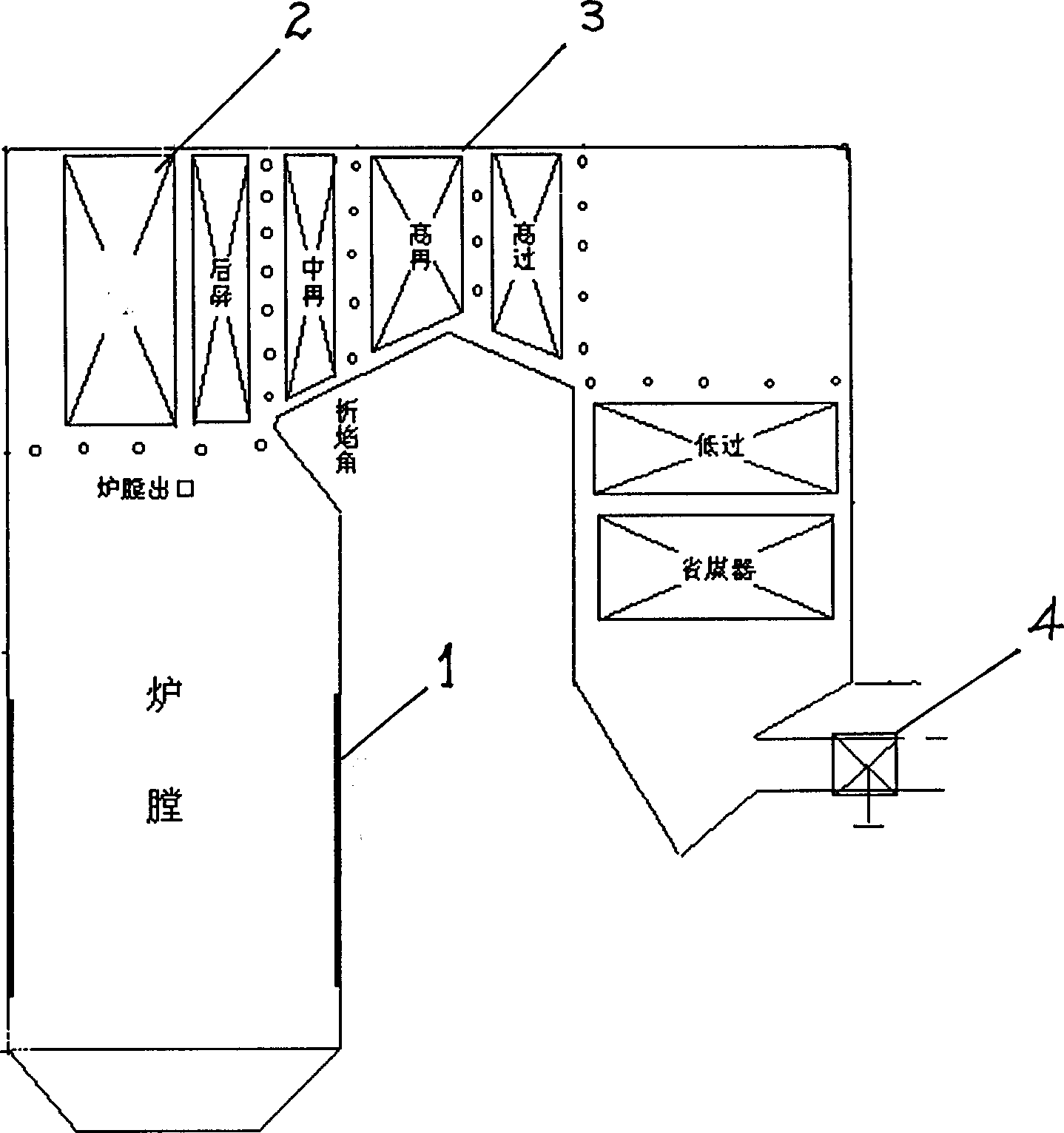

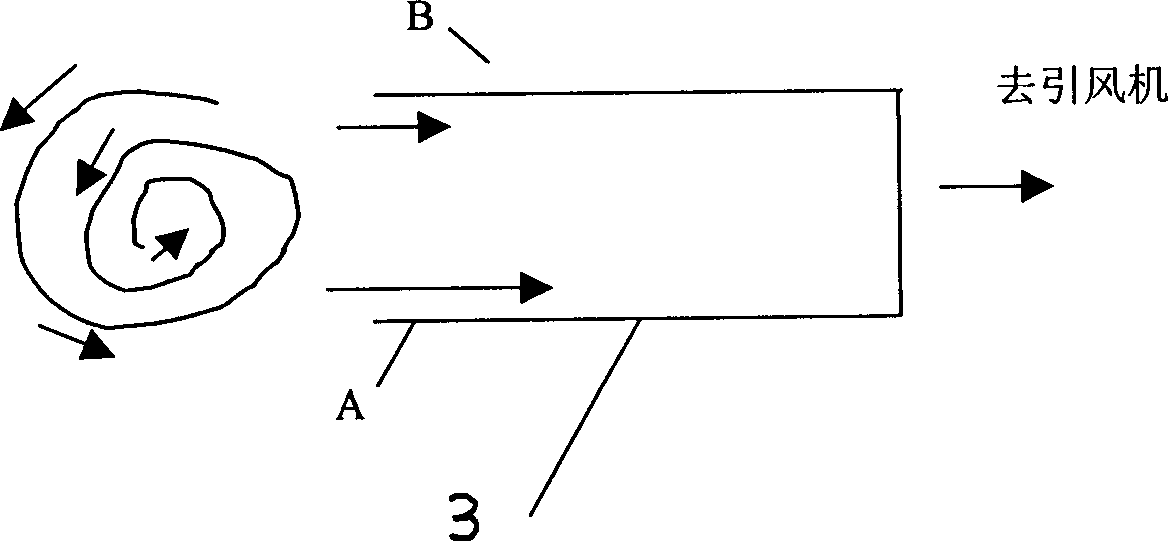

The present invention relates to a method for elimianting smoke speed deviation of horizontal flue of corner-fired boiler and is characterized by that at the outlet of furnace cavity of said boiler a rectangular warped separation screen, and the warped direction of said separation screen is opposite to the rotation direction of gas flow in the furnace. Said ivnention does not increase manufacture cost, does not change steam side flow path, and can retain advantages of corner combustion, and can greatly reduce smoke speed deviation and can make boiler more stable, safe and high-effective operate.

Description

technical field [0001] The invention belongs to the technical field of thermal power generation, and in particular relates to a method for eliminating the smoke velocity deviation of a horizontal flue of a four-corner injection-fired boiler. Background technique [0002] The pulverized coal suspension tangential combustion boiler with four-corner tangentially arranged burners (abbreviated as four-corner tangential combustion boiler, also known as injection-fired boiler) is a boiler commonly used in thermal power plants at present. This kind of boiler adopts chain ignition and rotary combustion, and its characteristic is that it can fully mix pulverized coal, oxygen and high-temperature flue gas in the low-pressure area in the center of the furnace. This kind of boiler has the advantages of strong turbulent mixing, high combustion efficiency, and wide adaptability to coal types. However, because the annular airflow in the furnace spirals up to the furnace outlet, there is re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F23J13/00

Inventor 李永光

Owner SHANGHAI UNIVERSITY OF ELECTRIC POWER

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com