Charging equipment fo r non-contact power transmission, power absorbing equipment and charging system

A technology for charging equipment and power transmission, applied in electromagnetic wave systems, battery circuit devices, circuits, etc., can solve the problems of magnetic coupling reduction, magnetic core energy loss, magnetic core saturation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

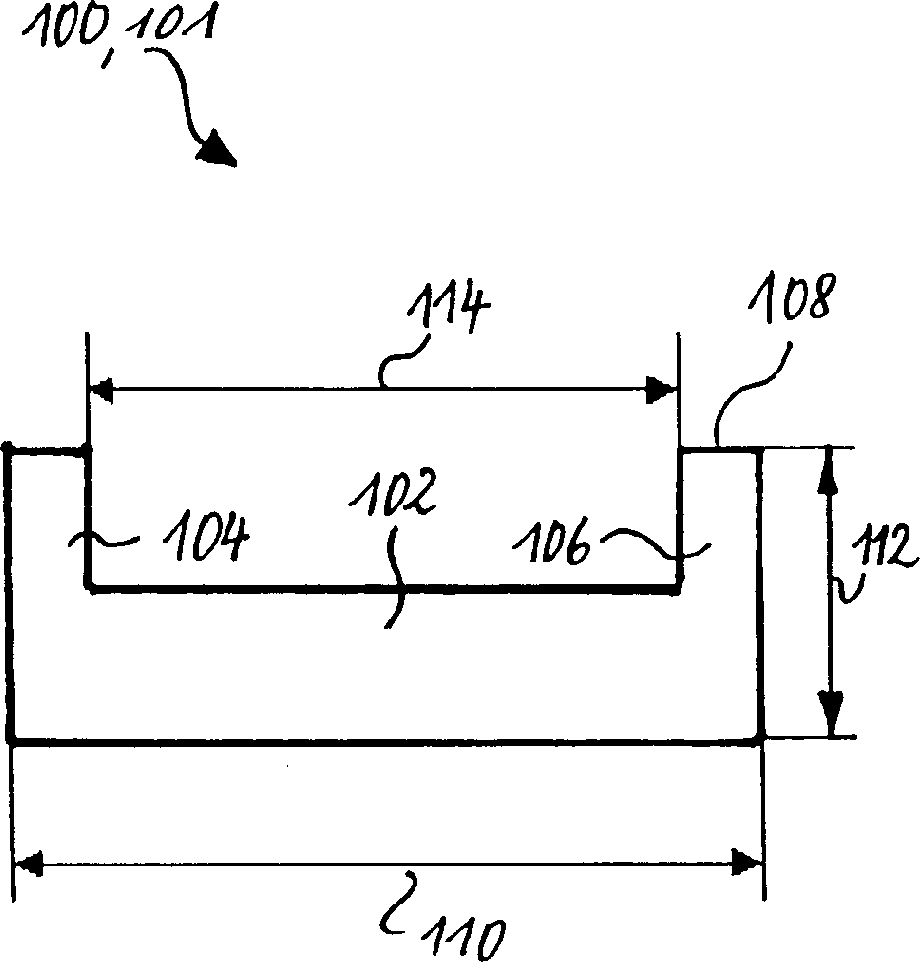

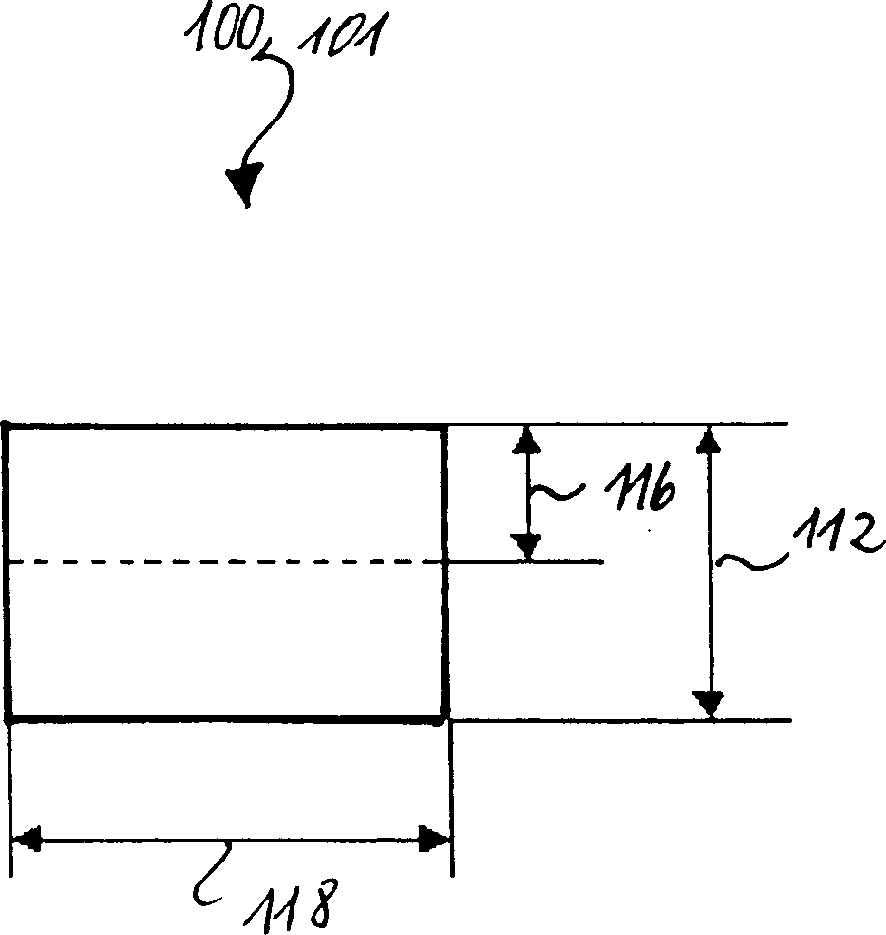

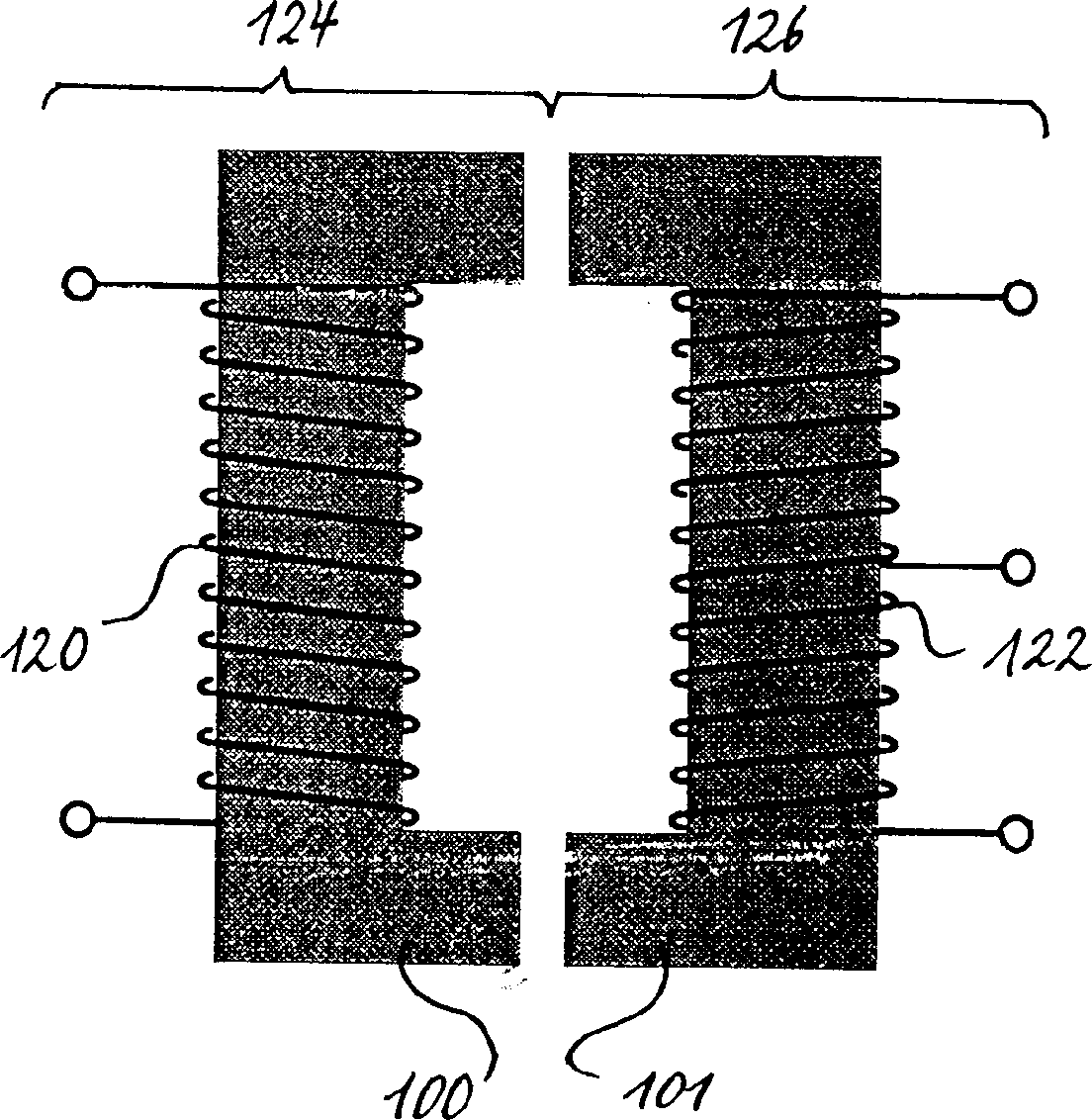

[0014] figure 1 and figure 2 is a side view of a ferrite core 100, which theoretically can be used for both the primary side and the secondary side according to the present invention. The ferrite core 100 is substantially U-shaped because this shape allows for the greatest possible coupling between the primary and secondary sides. The ferrite core 100 includes a base region 102 and two arm regions 104 , 106 each having a pole face 108 . According to the present invention, winding coils (only in image 3 shown in ) is disposed on the base region 102 of the U-shaped ferrite core. In order to keep the magnetic coupling between the two pairs of pole faces of the ferrite core 100 small, it is important that the ferrite core 100 is flat relative to its length. From figure 1 It can be seen that the length 110 of the base region is 2 to 3 times the projecting length 112 of the arm regions 104, 106, and the ratio of the inner length 114 of the base region 102 to the inner length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com