Internal and external fin tube and fin tube group

A technology of finned tubes and fins is applied in the field of gas-gas heat exchangers to achieve the effects of high heat transfer efficiency, reasonable structural design and saving of raw material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

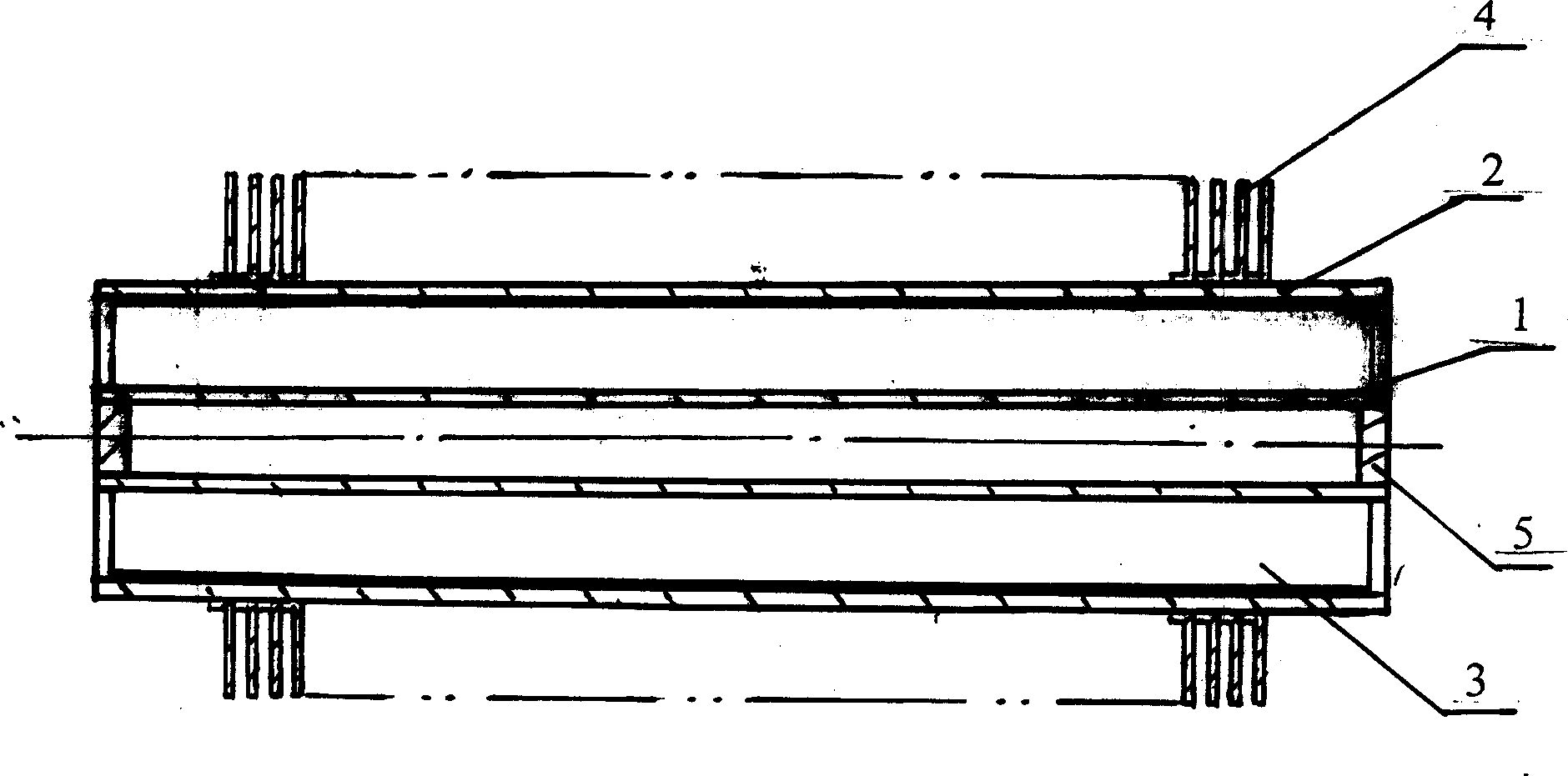

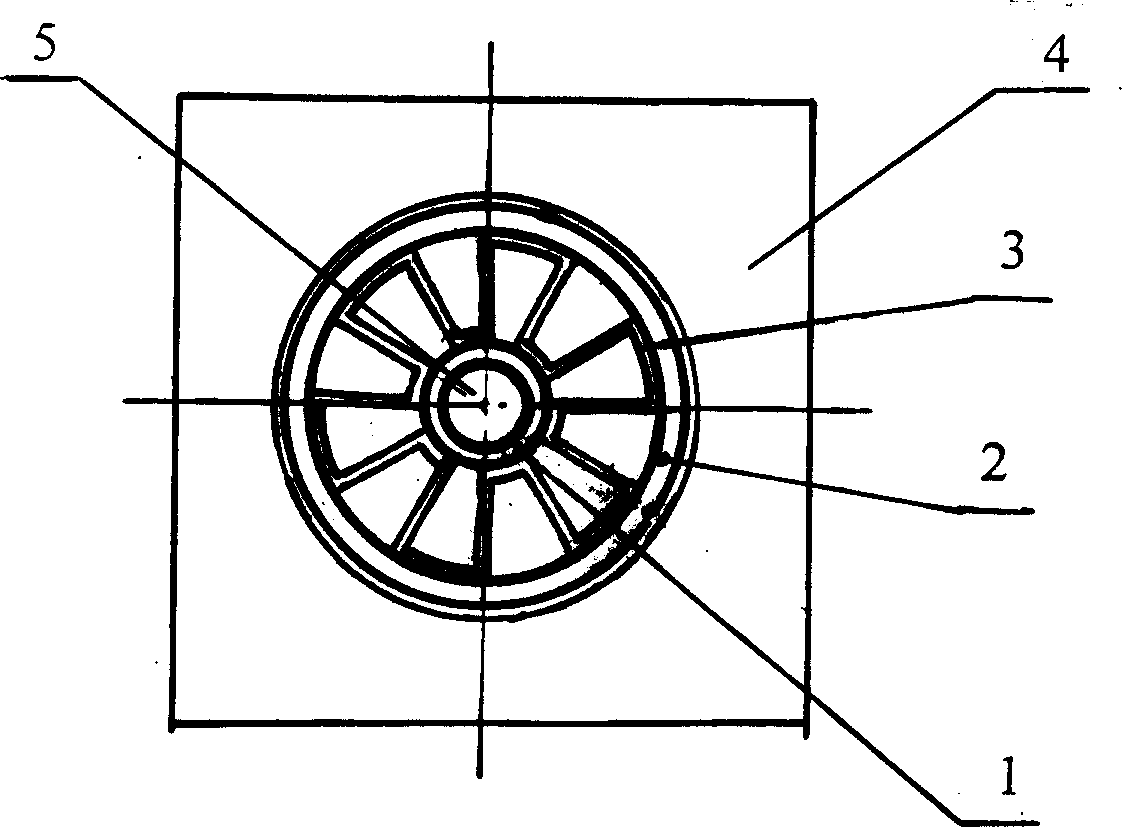

[0014] attached figure 1 , 2 Showing the sectional view of an embodiment of the inner and outer finned tubes of the present invention, the inner core 1 and the outer tube 2 are both smooth tubes, the outer tube 2 is provided with an inner core 1, and a straight tube is arranged between the inner core 1 and the outer tube 2. Shaped folded fins 3, square single-tube hole plate-shaped fins 4 are arranged on the outer wall of the outer tube 2, the inner core 1 is a round tube with an axial inner hole, and the two ends are sealed with plugs 5, forming the inner and outer fins of the present invention Tube.

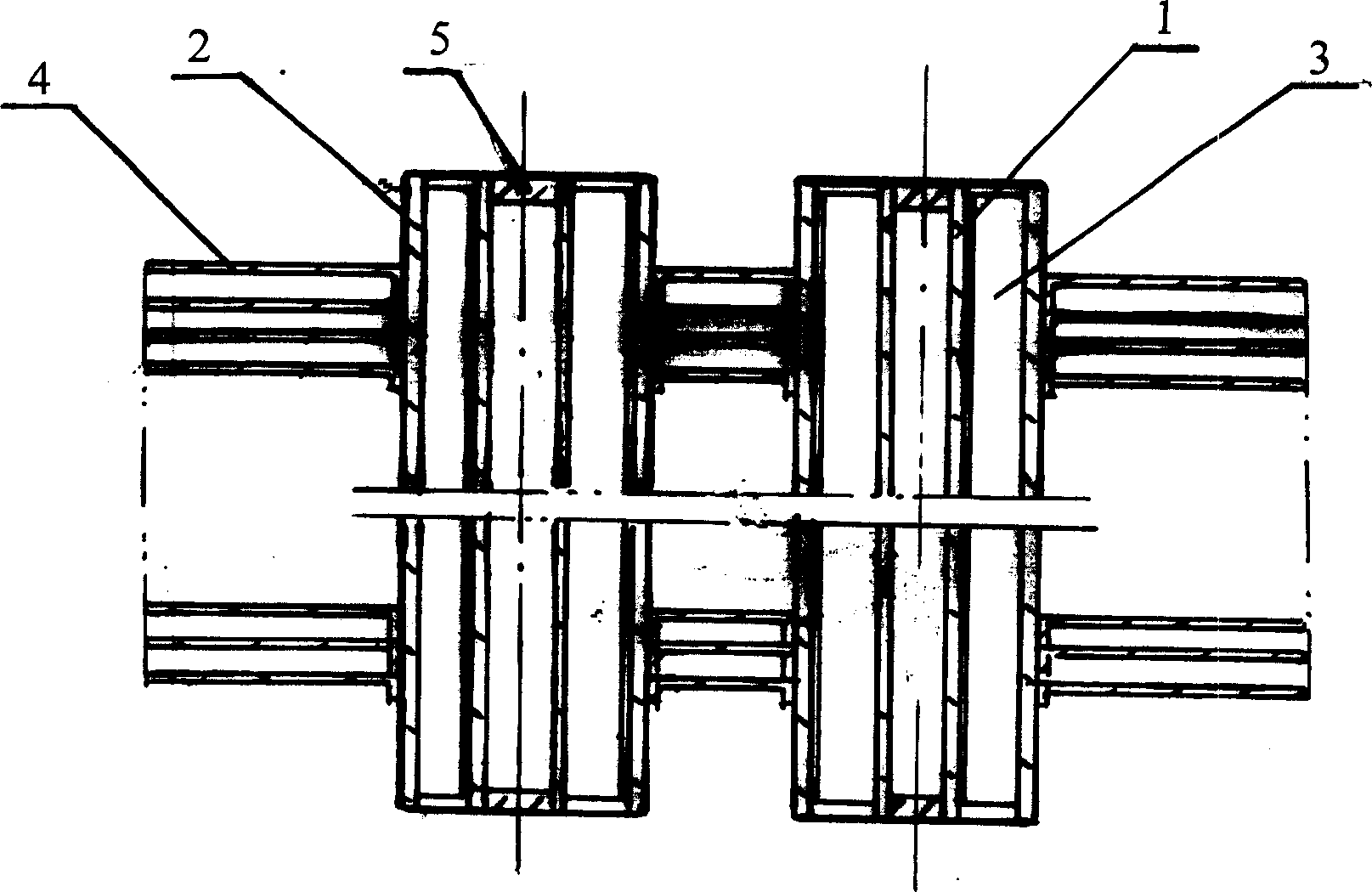

[0015] attached image 3 , 4 Show the structural diagram of the inner and outer finned tube clusters of the present invention, the inner core 1 and the outer tube 2 are all smooth tubes, the fins 3 are flat folded fins, the fins 4 are flat plate fins with multi-tube holes, and the outer tube 2. There is an inner core 1 inside. Straight folded fins 3 are arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com