LED module

A technology of LED module and collimator, which is applied in the direction of instruments, lighting and heating equipment, semiconductor devices of light-emitting components, etc., can solve the problem of limited maximum size of LED modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

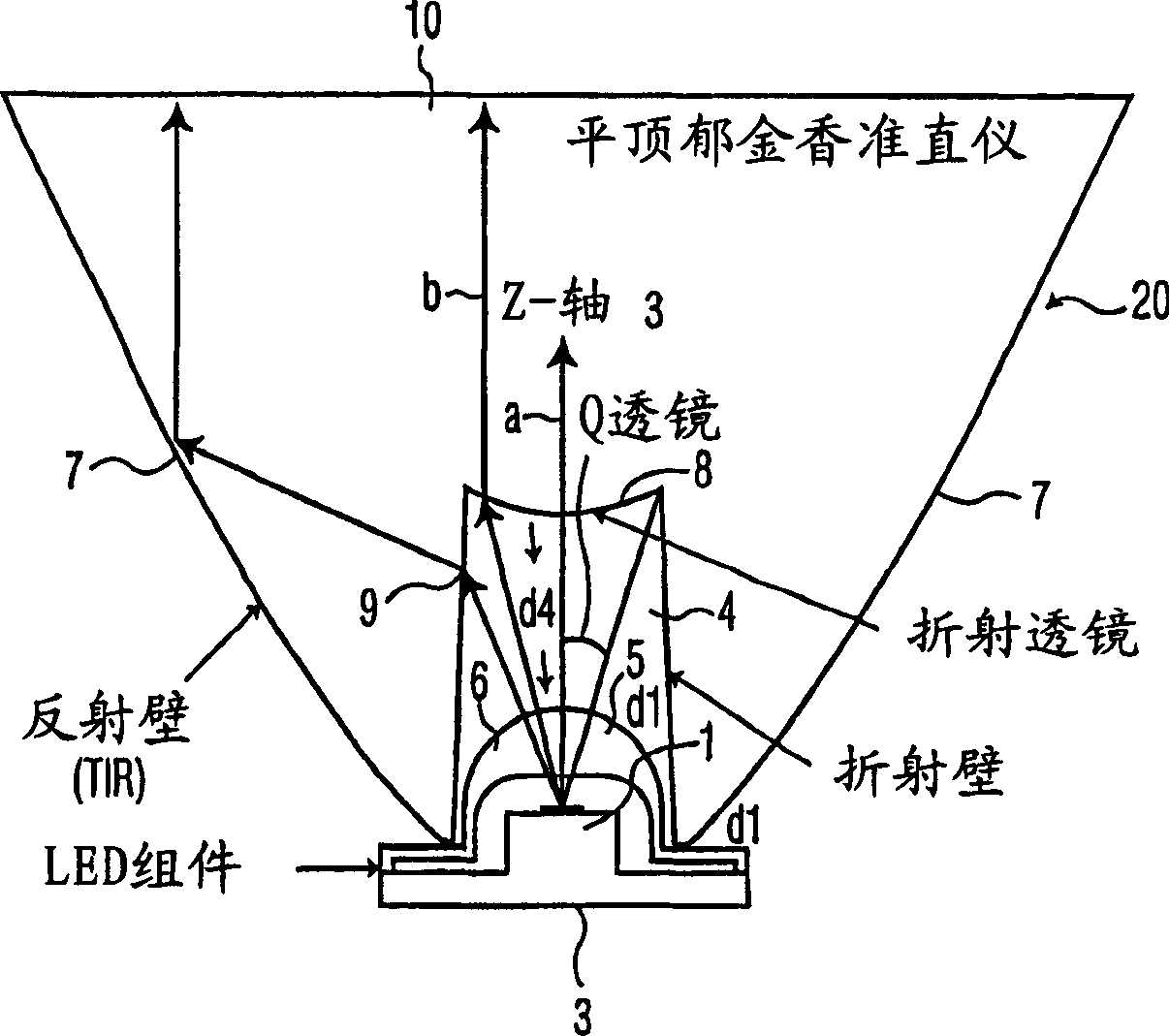

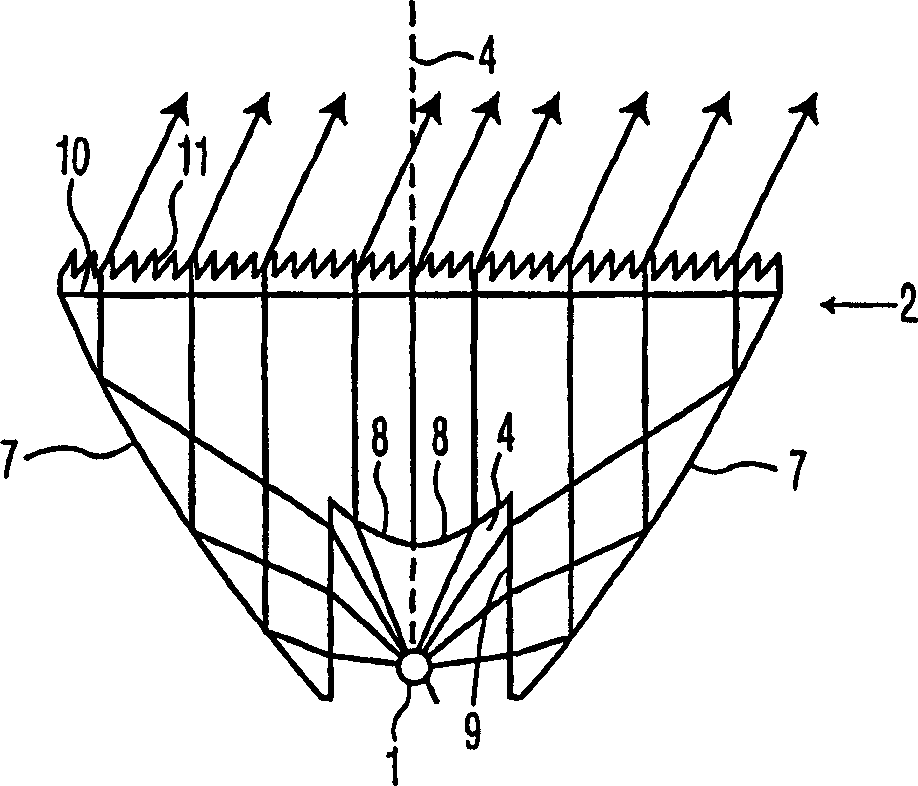

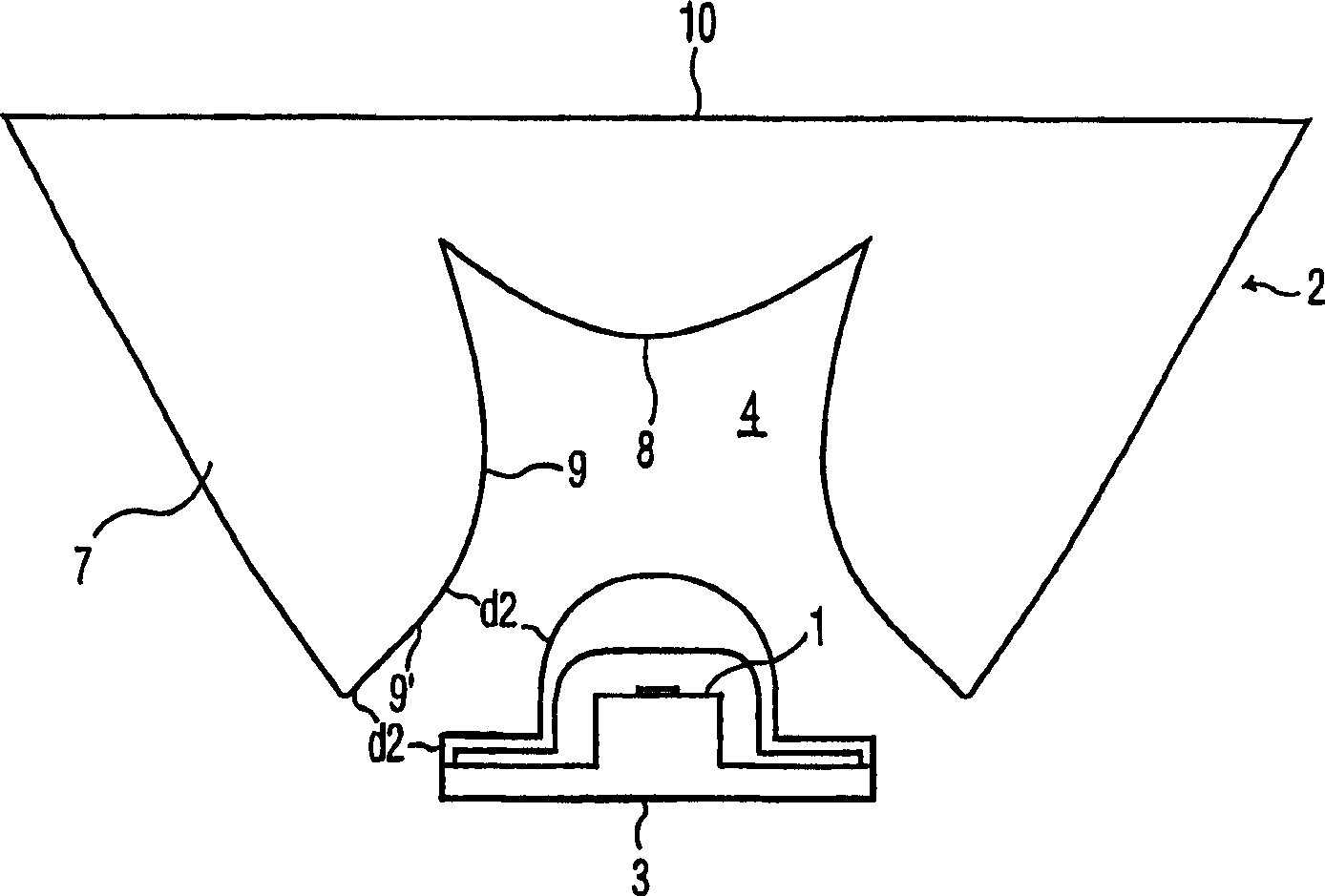

[0037] refer to Figure 1A with 1B , which respectively illustrate the prior art and the above-mentioned collimating element described in WO-A00 / 42,062, an LED light source or module 1 is associated with an embodiment of the collimating element 2 . The LED 1 is placed in the recess 4 of the bowl-shaped collimating element 2 . The collimating element 2 has an optical axis 3 and comprises an element body 4 for emitting light during operation. exist Figure 1A In the example shown, the body 5 of the LED 1 is provided with a light-transmitting housing 6, for example in the form of a lens. exist Figure 1B In the example, the LED is represented by a dot. The collimating element 2 has an optical axis 3 which coincides with the optical axis 3 of the LED 1 . The shape of the collimating element 2 is chosen such that the light emitted from the LED 1 is emitted by the optical system in a direction parallel to the optical axis 3 of the collimating element 2 . The shape of the curved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com