Thermosetting plastic extruding and pelletizing process

An extrusion granulation and thermosetting technology, which is applied in the extrusion granulation process of thermosetting plastics, can solve the problems of irreparable economic loss and system inoperability, and achieve the effects of easy control, improved environmental quality, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further illustrate the present invention below in conjunction with embodiment

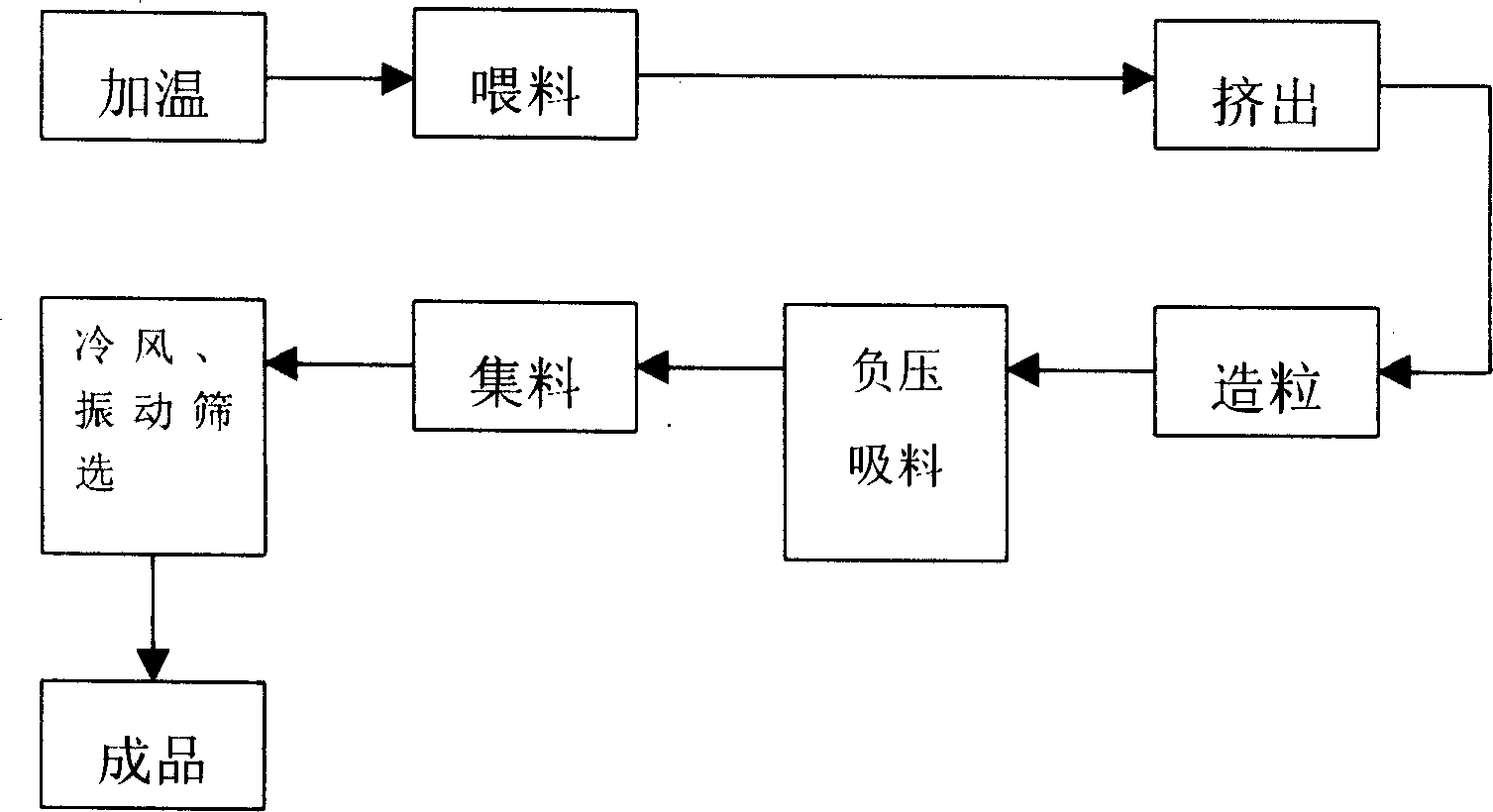

[0030] refer to figure 1 , The process of the present invention consists of the following processes, heating, feeding, extrusion, granulation, negative pressure suction, cyclone separation of aggregates, cold wind vibration screening, finished product packaging.

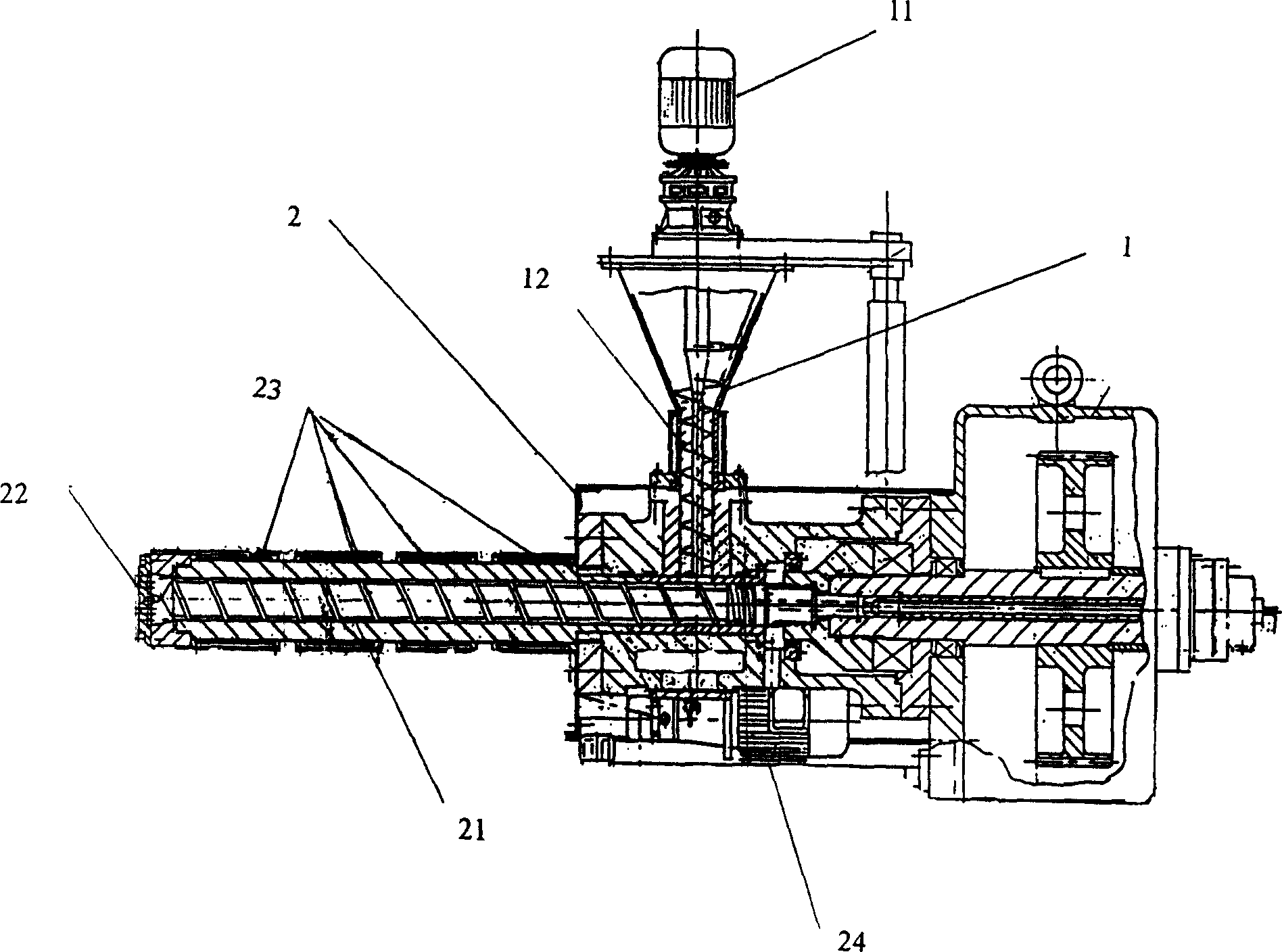

[0031] After driving, heat the electric heating mantle first, and then inject the plasticized thermosetting plastic (chopped glass fiber reinforced phenolic molding compound) into the extrusion device 2 from top to bottom through the forced feeding device 1. The forced feeding device 1 can be provided with a screw device 12, and the screw device 12 can rotate with the motor 11 at the upper end of the feed inlet, so that the raw materials can be mixed evenly before being injected into the extrusion device 2. After the raw material enters the extrusion device 2 , it advances helically toward the die 22 along with the screw 21 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com