Backflush filter, in particular for filtering lubricant oil

A countercurrent washing and filter technology, which is applied to the installation/connection of fixed filter element filters, membrane filters, lubricant purification devices, etc., and can solve the problem of large loss of filtrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

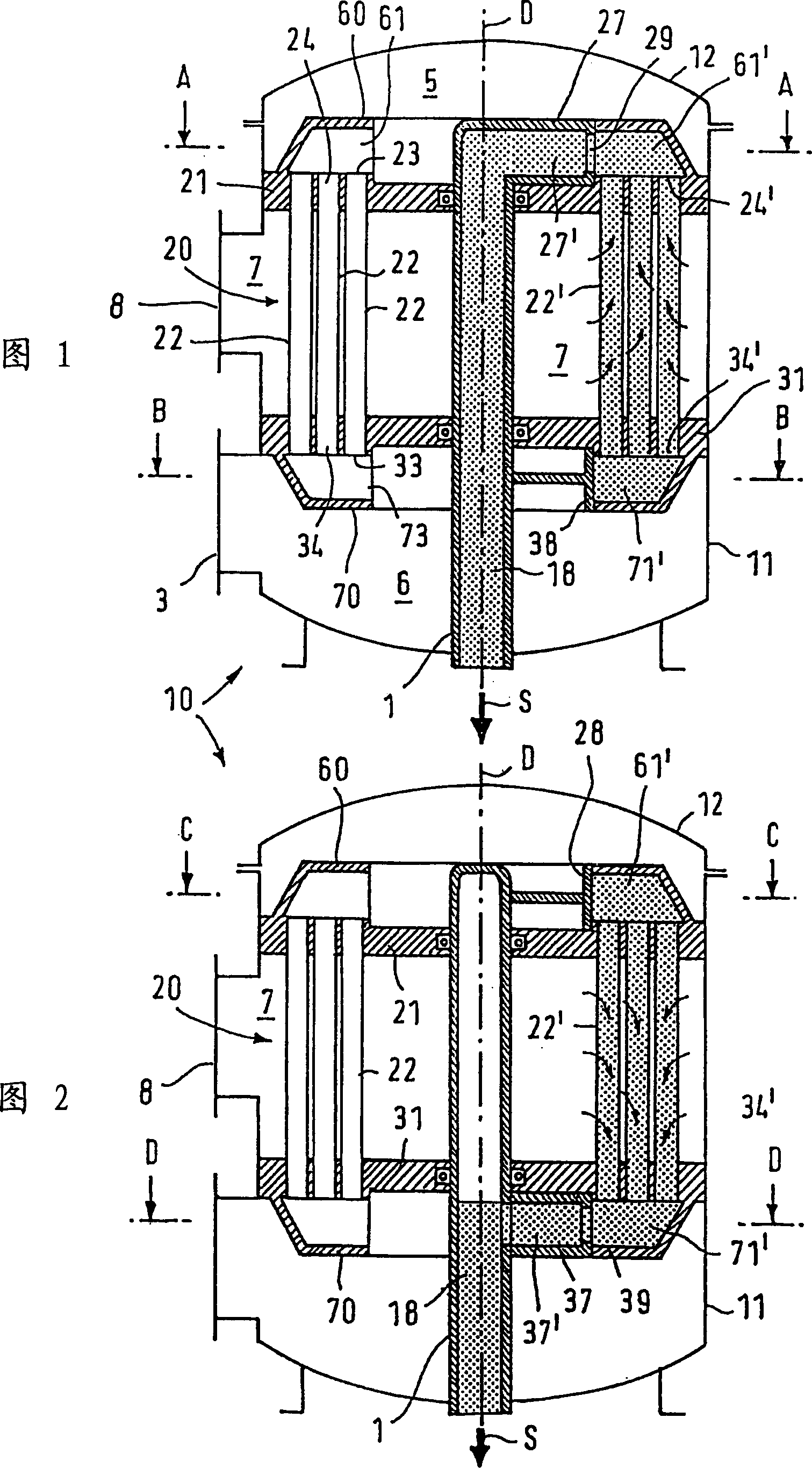

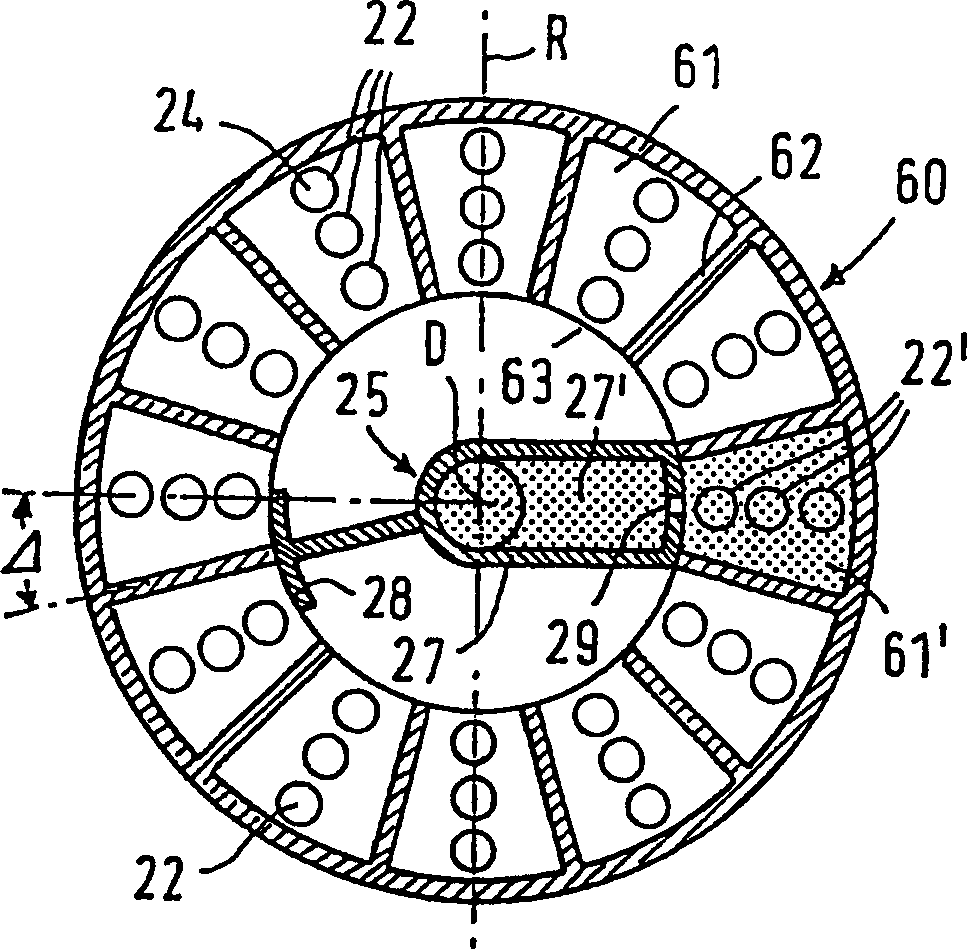

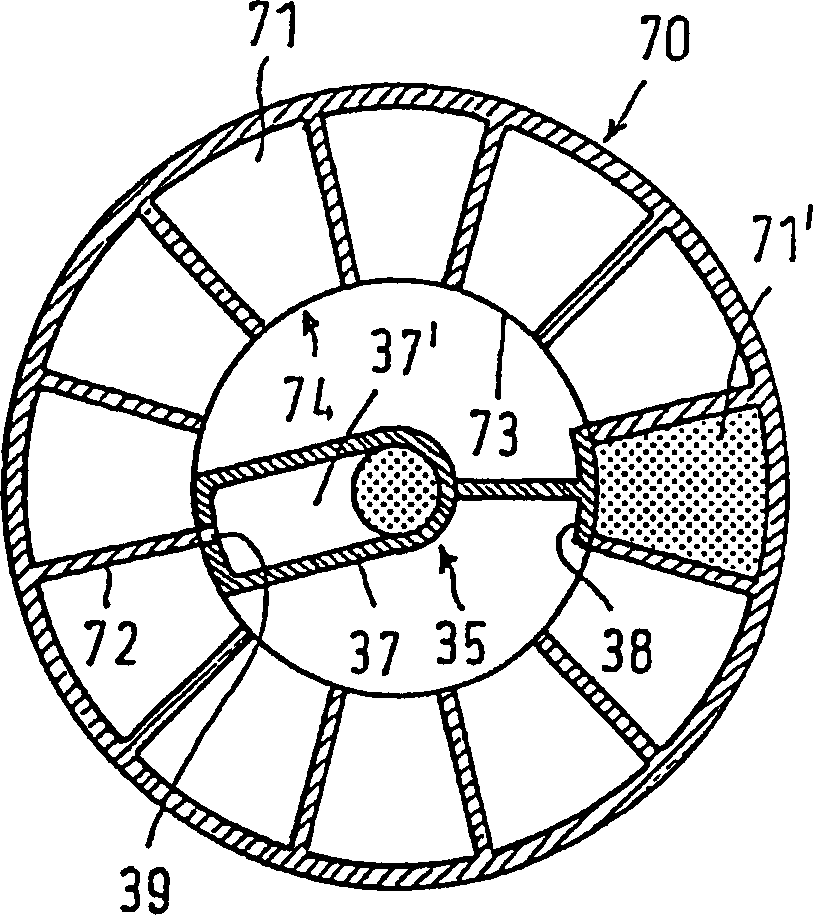

[0019] 1 and 2 are schematic diagrams of a backwash filter, which includes a filter housing 11 and a housing cover 12 . The filter insert 20 is arranged in the inner space of the filter housing 11 and the housing cover 12 and comprises a plurality of filter parts 22, 22' placed concentrically around the axis of rotation D of the filter. As will be explained below, the filter element 22 performs filtering and the filter element 22' performs backwashing. The filter parts 22, 22' are clamped between the upper perforated plate 21 and the lower perforated plate 31, so that during the filtering operation, the oil sludge to be filtered that enters the backwashing filter 10 through the filter inlet 3 flows into the filter element 22. In the upper inflow end 24 and the lower inflow end 34 . The sludge flows from the inside through the filter wall of the filter element 22 to the outside and enters the filter chamber 7 as filtrate. The filtrate comes out of the filter cavity and is sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com