Flushing and sand-removing device for ship flap rudder bearing

A flap rudder and bearing technology, which is applied to ship cleaning devices, ship hulls, ship construction, etc., can solve problems such as high cost and poor effect, and achieve the effects of simple operation, simple structure, and increased flushing speed and flushing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

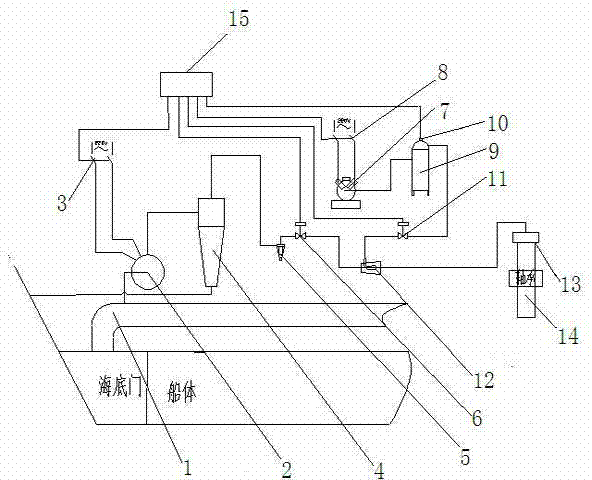

[0015] Such as figure 1 As shown, the present invention has a seawater main pipe 1, the bottom of the seawater main pipe 1 leads to the seabed door, the top of the seawater main pipe 1 is connected to the water inlet of the seawater pump 2, and the water outlet of the seawater pump 2 is connected to the top of the narrow cone type hydrocyclone 4. The water inlets are connected, the bottom of the narrow cone hydrocyclone 4 is a thin cone end, and the top of the narrow cone hydrocyclone 4 is connected to the ultrafine filter 5 through a pipeline, and the ultrafine filter 5 passes The clean seawater flushing electromagnetic valve 6 is connected with the venturi injector 12. In this way, the seawater with sediment is pumped into the narrow cone hydrocyclone 4 to carry out the cyclone separation of mud and water. Under the action of the centrifugal force of the cyclone, the sediment is discharged from the outlet of the narrow cone end at the bottom, and the clear water is discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com