Fiber anticounterfeit paper and manufacture method thereof

An anti-counterfeiting paper and fiber technology is applied in the field of anti-counterfeiting paper to achieve the effect of improving the anti-counterfeiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

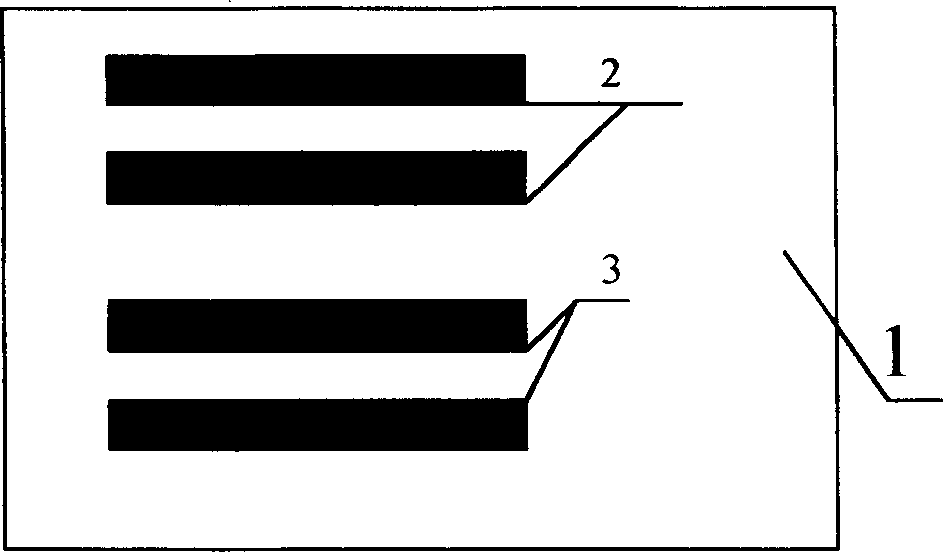

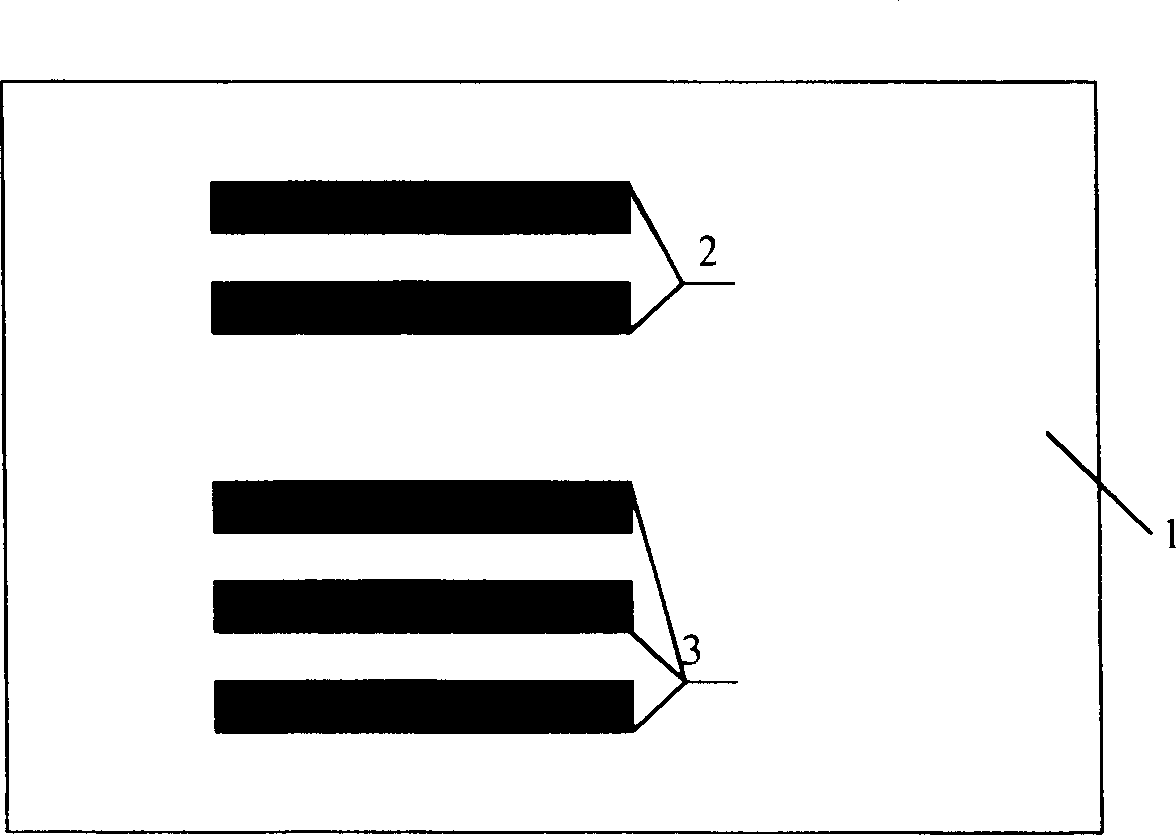

[0020] Example 1: see figure 1 , figure 1 Two black infrared fibers 2 and two black magnetic fibers 3 are mixed on the middle anti-counterfeiting paper 1, and the shapes and lengths are similar. Black infrared fiber refers to the chemical fiber that transmits in the near-infrared band of 700-1100nm, is non-magnetic and can be combined with paper; black magnetic fiber refers to the chemical fiber that absorbs in the near-infrared band of 700-1100nm and has magnetic characteristics. Chemical fibers that can be combined with paper. Under the infrared detector (manufactured by Yunnan Zhihai Optoelectronics Technology Co., Ltd.), the black magnetic fiber 3 can be observed, while the black infrared fiber 2 disappears. The magnetic signal of the magnetic fiber 3 can be detected by a magnetic reader.

Embodiment 2

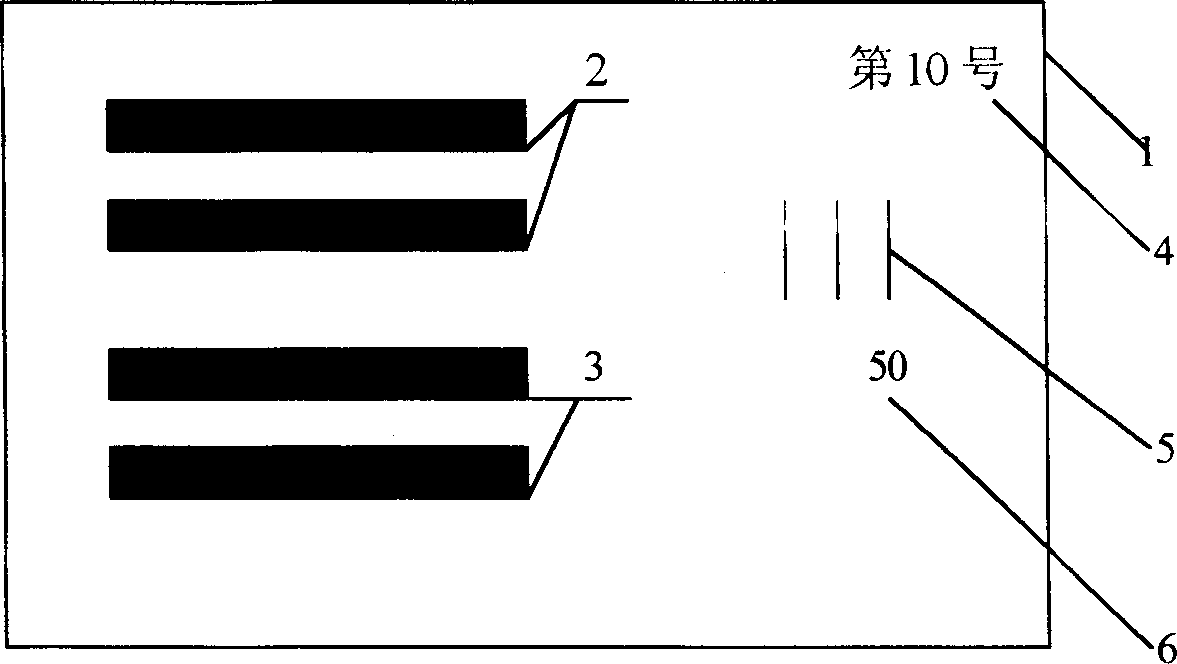

[0021] Example 2: see figure 2 , figure 2 In addition to being mixed with two black infrared fibers 2 and two black magnetic fibers 3, the middle anti-counterfeiting paper 1 is also printed with number 4, barcode 5 and serial number 6 information uniquely corresponding to the characteristics of the two fibers, forming comprehensive information. In the process of making the anti-counterfeit paper, the above-mentioned comprehensive information can be set as an anti-counterfeit information database and stored in the inspection device, so that the anti-counterfeiting of digital information can be realized, and the anti-counterfeiting effect can be further improved. The specific identification process is as follows: use infrared fiber and magnetic fiber sensors to read out the corresponding magnetic information and infrared information; correspond to the printed number to form associated information, and compare the unique features in the inspection device according to the unique...

Embodiment 3

[0022] Embodiment 3: the manufacture method of embodiment 1 fiber anti-counterfeiting paper, comprises the following steps: 1), utilize known methods such as dyeing method, wet spinning, dry spinning, black infrared through material (for example trichromatic pigment The mixture) is combined in the chemical fiber to prepare black infrared fiber, and its near-infrared region passes through: 2), using known methods such as dyeing, wet spinning, dry spinning, etc., black magnetic materials (such as oxidized Iron black) is combined in the chemical fiber, prepares the magnetic fiber identical with described infrared fiber outward appearance color, and it has magnetism, and near-infrared region absorbs; 3) in the process of producing safety paper, join in paper in the same proportion A paper with infrared fibers and magnetic fibers doped with similar hues is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com