A method and apparatus for processing a pulverulent or particulate material

A granular, equipment technology that can solve problems such as insufficiency in lighting and heating equipment, heating to dry solid materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

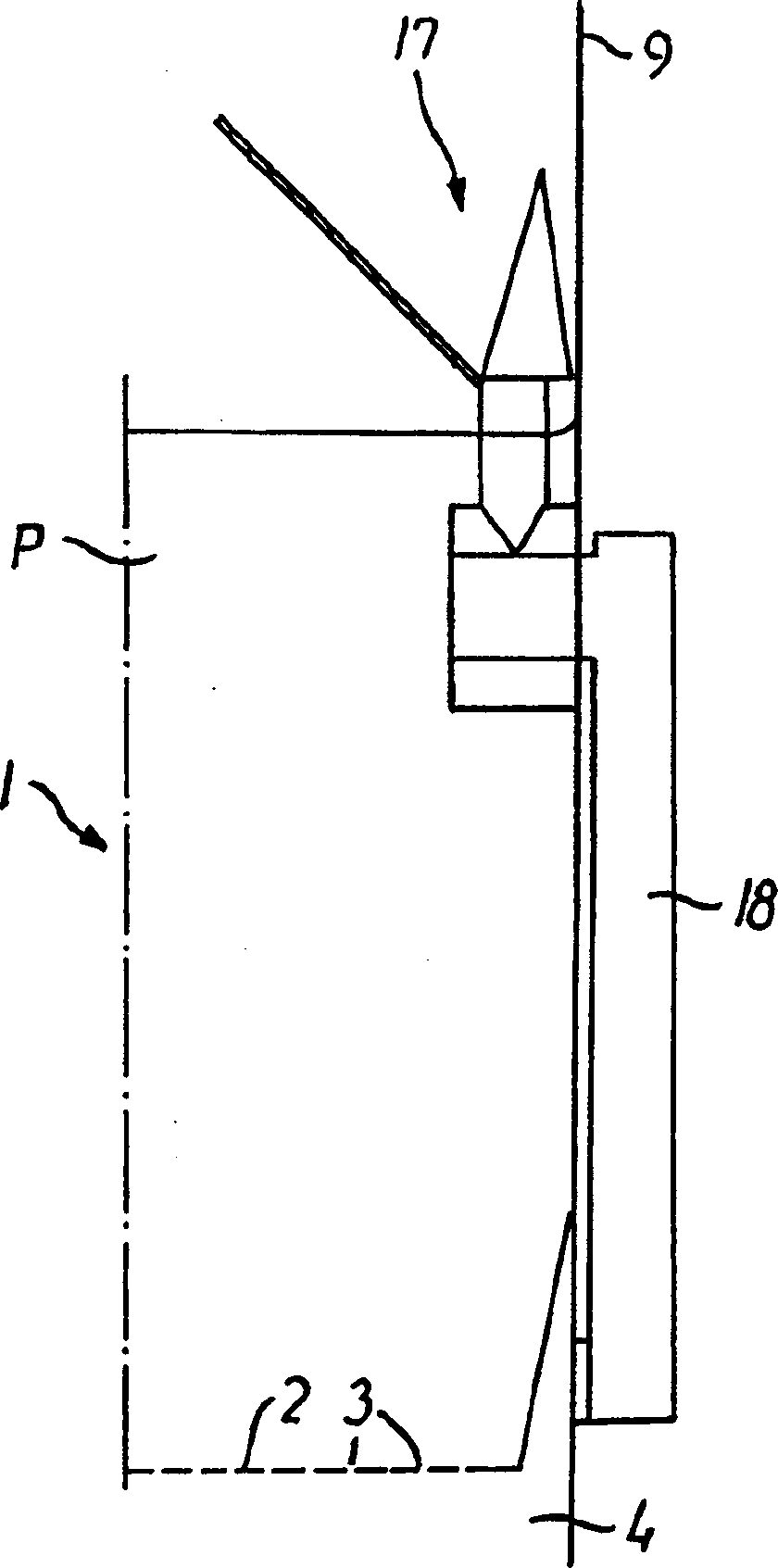

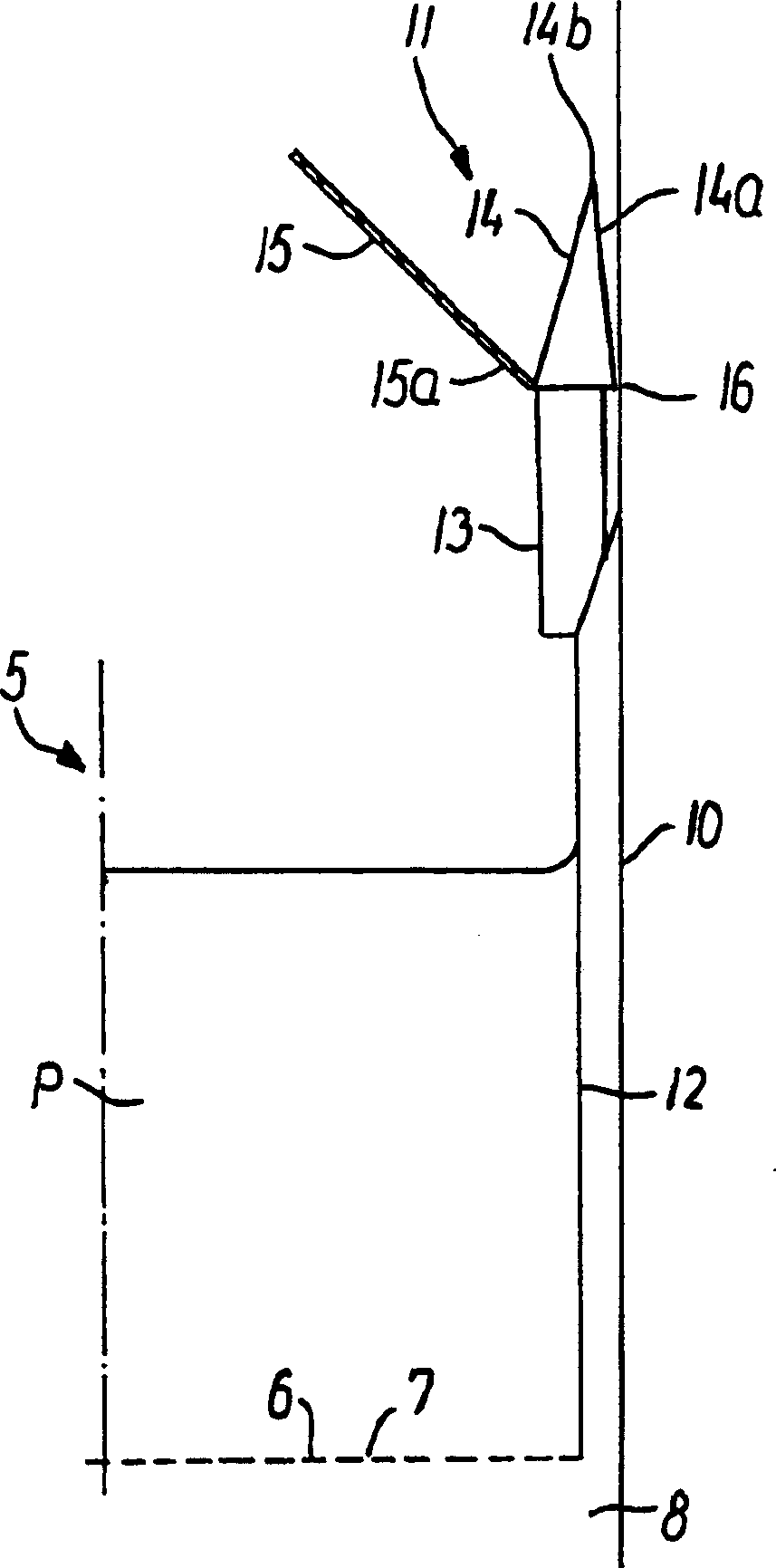

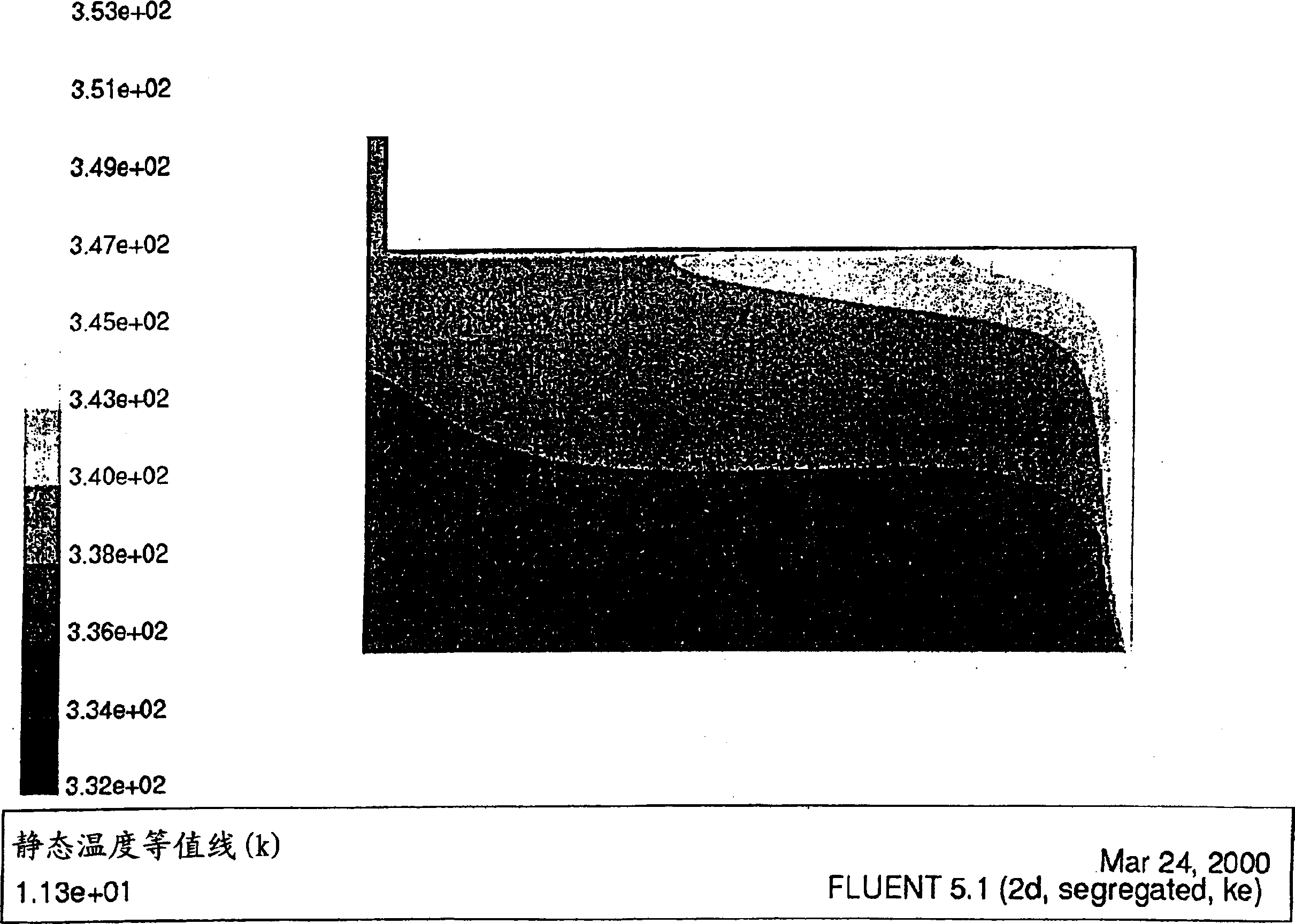

[0014] figure 1 and 2 A cut-away view of a first section 1 and a second section 5 of a fluidized bed apparatus for processing powdery or granular materials is shown respectively. Examples of such materials are milk products, ceramics, polymers, etc., which are dried, cooled or spray-granulated, for example in fluidized bed equipment. The method and device according to the invention are particularly advantageous for chlorine-containing materials, such as inorganic salts or polymers such as PVC.

[0015] The first section 1 of the apparatus is in the illustrated embodiment of the back-mixing type, in which powdered or granular material is supplied by distributor means (not shown) to a fluidized bed plate 2 on which the material forms a layer Material P. The height or thickness of the material depends on the type of material to be processed and can be adjusted with a suitable device such as a damper or overflow valve. The fluidizing gas is introduced from the plenum 4 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com