Process and apparatus for dispersing and surface modifying nano and micrometer particles by aerosol process

A micron particle and surface modification technology, which is applied to the surface coating liquid device, inorganic pigment treatment, special surface, etc., can solve the problem that the monodisperse system cannot be formed, the modifier cannot be coated, and the particle modification layer Difficult to control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

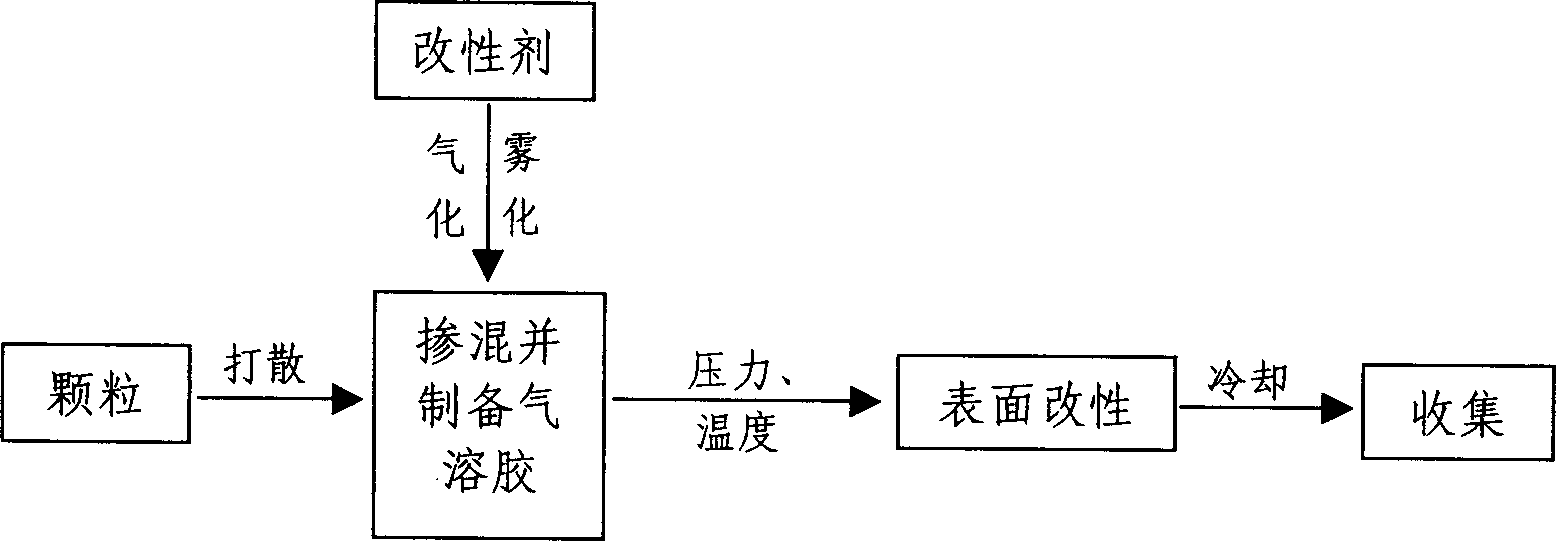

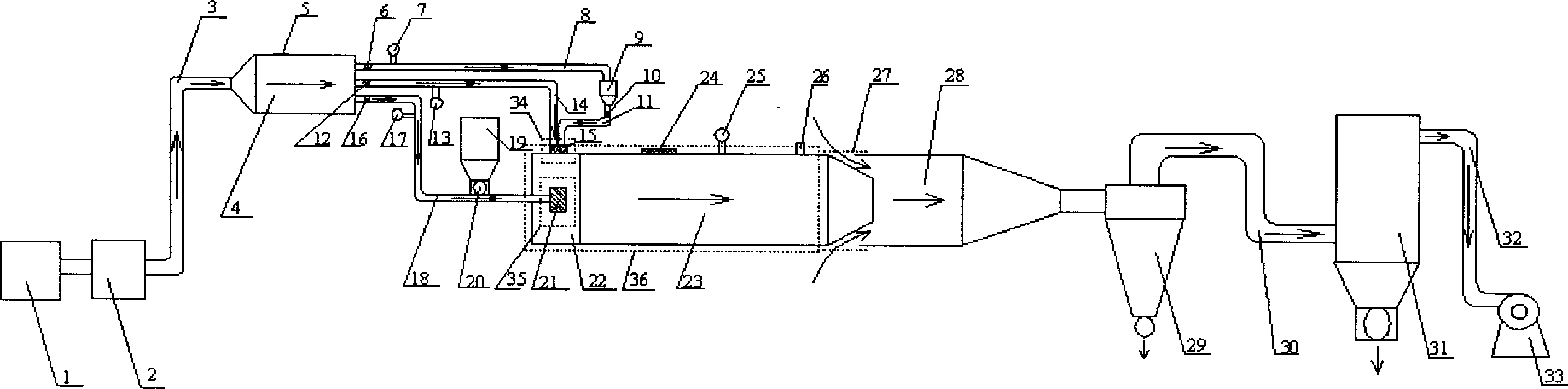

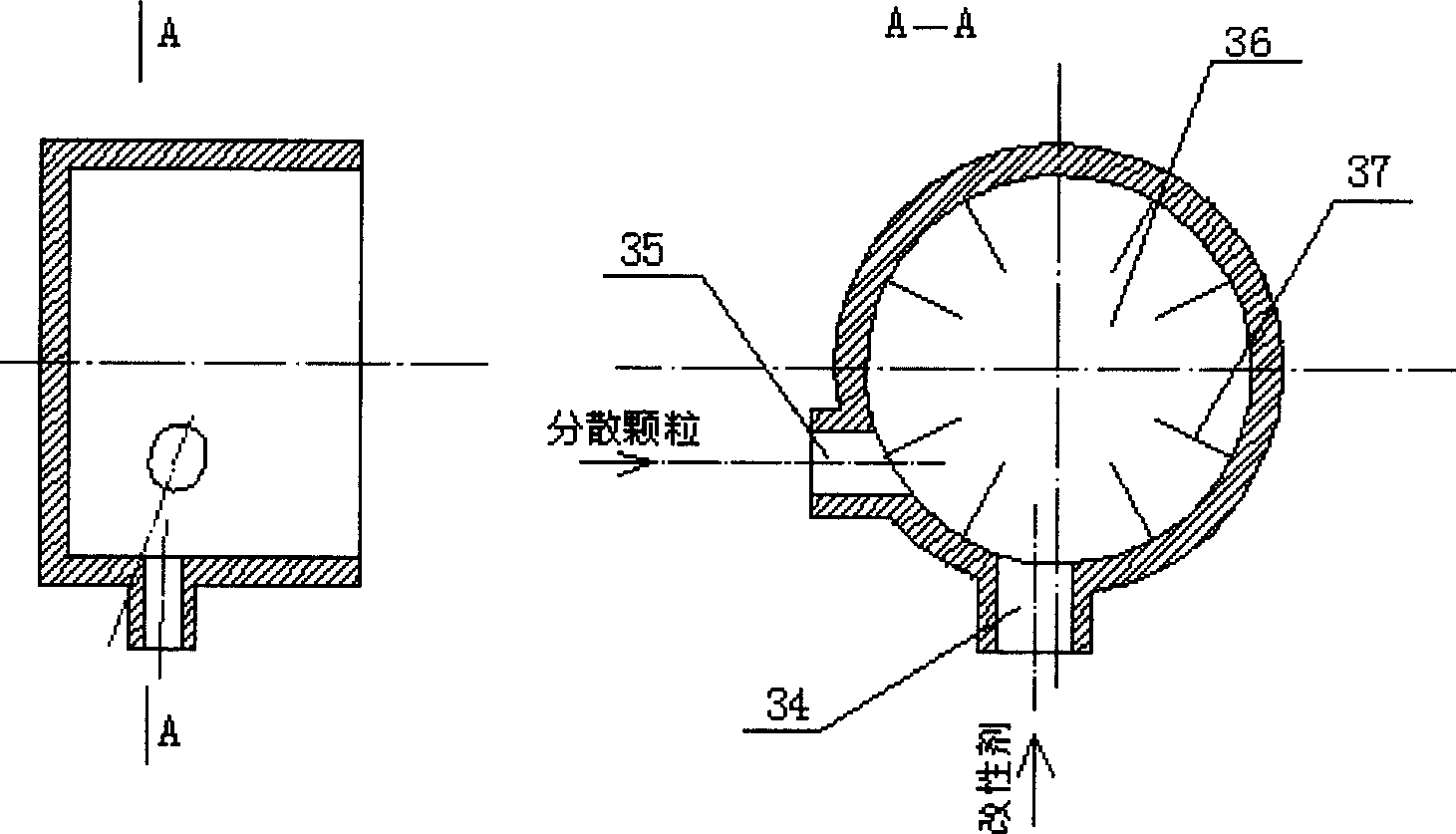

[0043] An aerosol nano or micro particle material dispersion and surface modification process such as figure 1 shown. The gas is pressed into the dryer by the compressor, and enters the heater to be heated; part of the heated high-temperature gas sends the particles in the particle silo into the particle dispersing device, and uses the strong turbulent flow field of the high-speed air flow to disperse the particles, and part of the modified The modifying agent in the agent container is input into the atomizer to atomize or vaporize the modifying agent; the atomized or gasified modifying agent is fully mixed with the dispersed particles to obtain an aerosol; control The temperature and pressure of the aerosol system are used to modify the surface of the particles; after a certain period of time, the aerosol is sprayed out from the nozzle, and the temperature is reduced to complete the surface modification of the particles; finally, the collection of the modified particles is co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap