Air conditioner and its liquid storage device and method for producing liquid storage device

A technology of liquid accumulator and container, applied in the field of oil return functional components, can solve the problems of large pressure loss, high production cost, no refrigeration capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

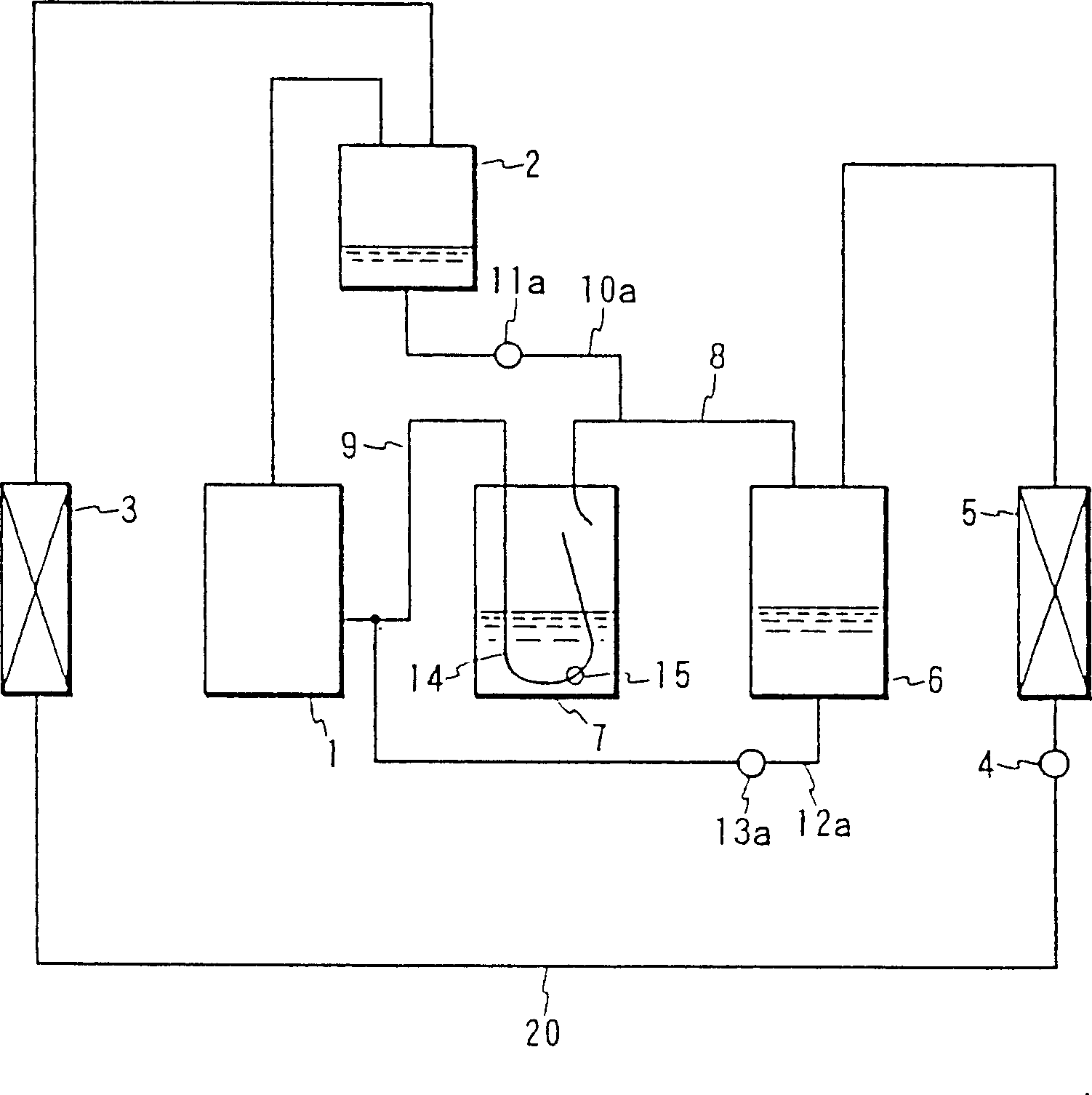

Embodiment 1

[0075] figure 1 It is the refrigerant circuit of the air conditioning system in the first embodiment of the present invention. In the drawing, numbers 1 to 9, 14 and 15 are associated with Figure 41 The refrigerant circuits shown are numbered for corresponding parts that are the same or similar and therefore will not be discussed here. The number 10a is the first oil return bypass connecting the oil separator 2 and the connecting pipe 8, and the number 11a is the first oil return device arranged at the midpoint of the pipeline of the first oil return bypass. The reference number 12a is the second oil return bypass connecting the bottom of the first liquid reservoir 6 and the connecting pipe 9, and the reference number 13a is the second oil return device arranged at the midpoint of the pipeline of the second oil return bypass 12a.

[0076] The flow process of refrigerant and lubricating oil is the same as that of the refrigerant circuit of a conventional air-conditioning sys...

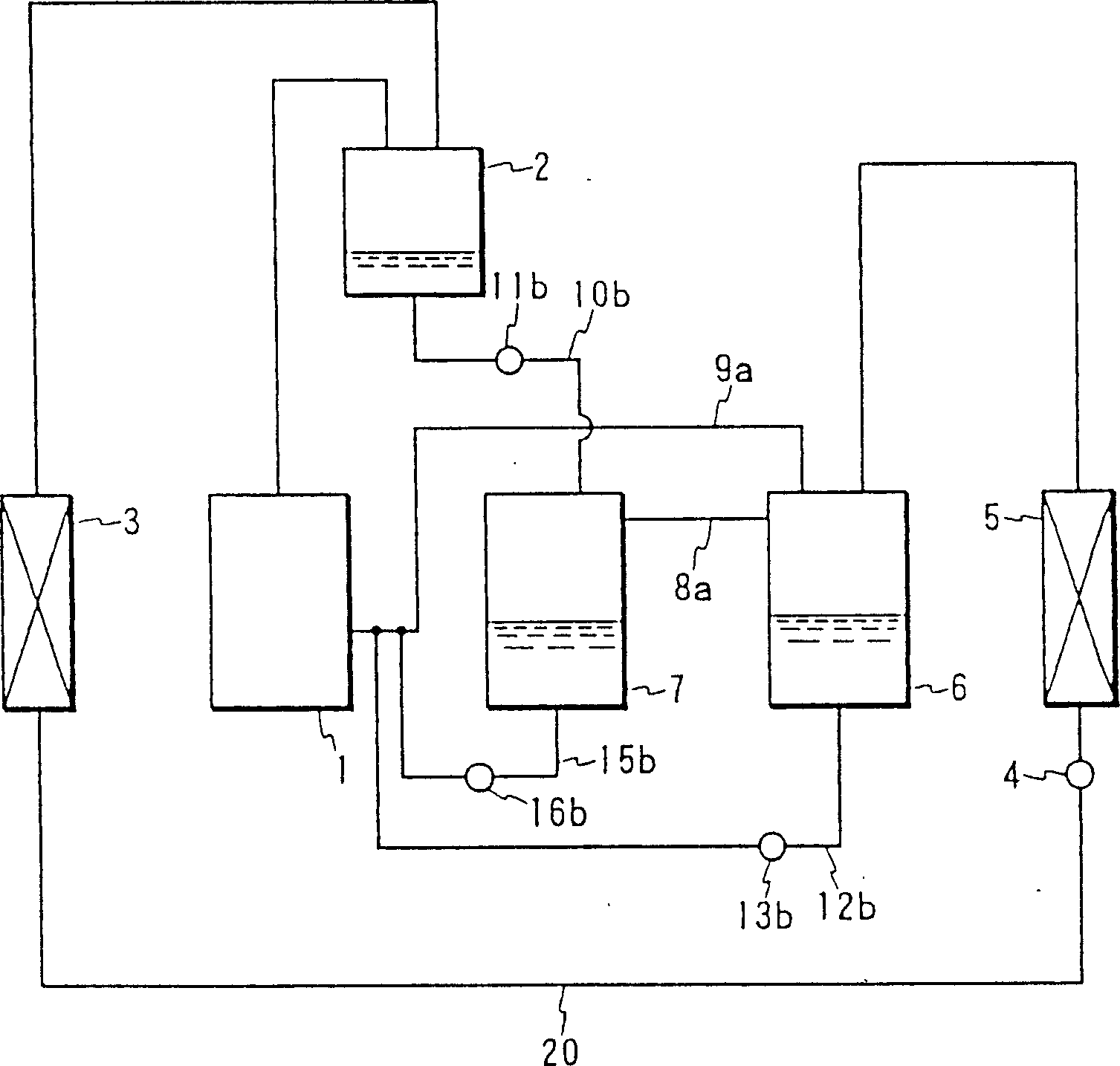

Embodiment 2

[0083] figure 2 It is the refrigerant circuit flow diagram of the air conditioning system according to the second embodiment of the present invention. In this figure, numbers 1 through 7 are associated with figure 1 The parts corresponding to the reference numerals of the refrigerant circuit of the air-conditioning system in the first embodiment shown are the same or similar, so no further discussion will be made here. The symbol 8a is a connecting pipe connecting the side top of the first liquid reservoir 6 and the side top of the second liquid reservoir 7, the symbol 9a is a connecting pipe connecting the first liquid reservoir 6 and the compressor 1, and the symbol 10b is The third oil return bypass connecting the oil separator 2 and the second liquid reservoir 7, the symbol 11b is the third oil return device arranged at the midpoint of the pipeline of the third oil return bypass 10b, and the symbol 15b is connected to the second oil return bypass. The bottom of the liqui...

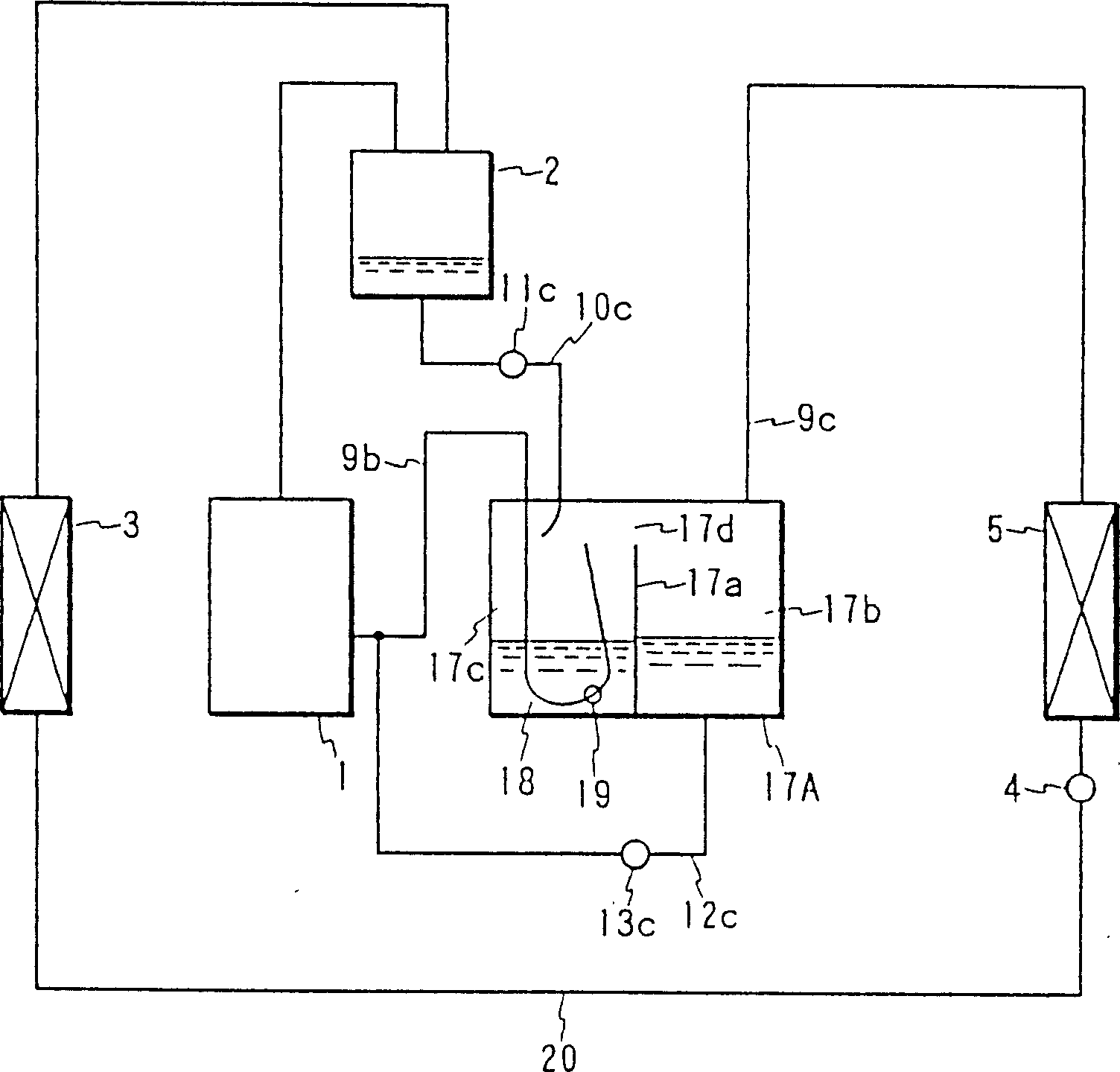

Embodiment 3

[0089] image 3 It is the refrigerant circuit flow diagram of the air conditioning system according to the third embodiment of the present invention. In this figure, numbers 1 to 5 are associated with figure 1 The parts corresponding to the reference numerals of the refrigerant circuit of the air-conditioning system in the first embodiment shown are the same or similar, so no further discussion will be made here. Symbol 17A is a liquid reservoir, symbol 9b is a connecting pipe that flows out of the liquid reservoir 17A and flows into the compressor 1, symbol 9c is an inflow pipe that flows from the indoor heat exchanger 5 into the liquid reservoir 17A, and symbol 17a is used to transfer the reservoir The interior of the liquid container 17A is divided into two cavities by a partition, the symbol 17b is the first chamber of the liquid reservoir 17A separated by the partition 17a; the label 17c is the second cavity of the liquid reservoir 17A separated by the partition 17a , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com