Control system for indirectly heated cathode ion source

An indirect heating and ion source technology, applied in the field of ion sources, can solve problems such as the difficulty of tuning large beam current transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

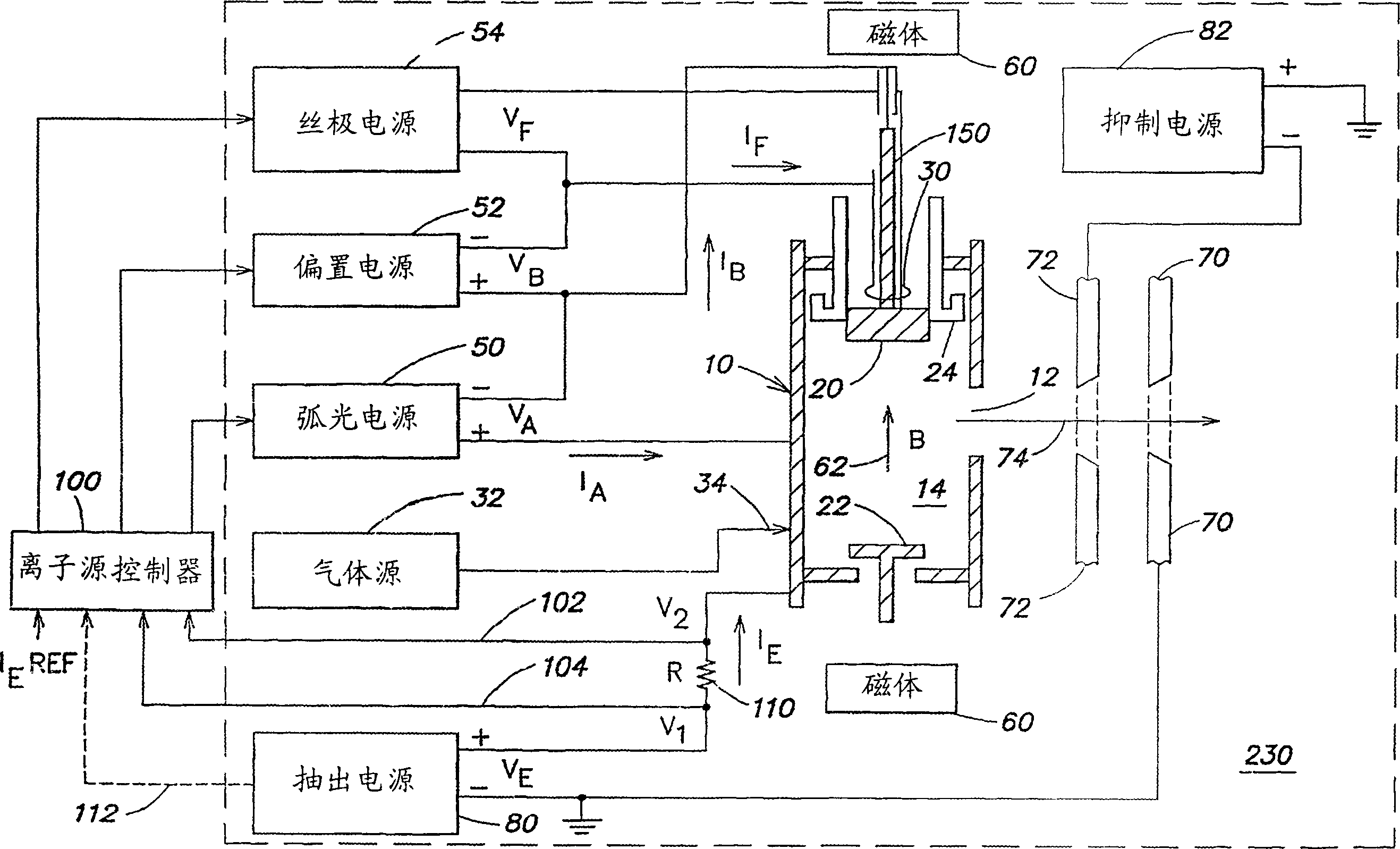

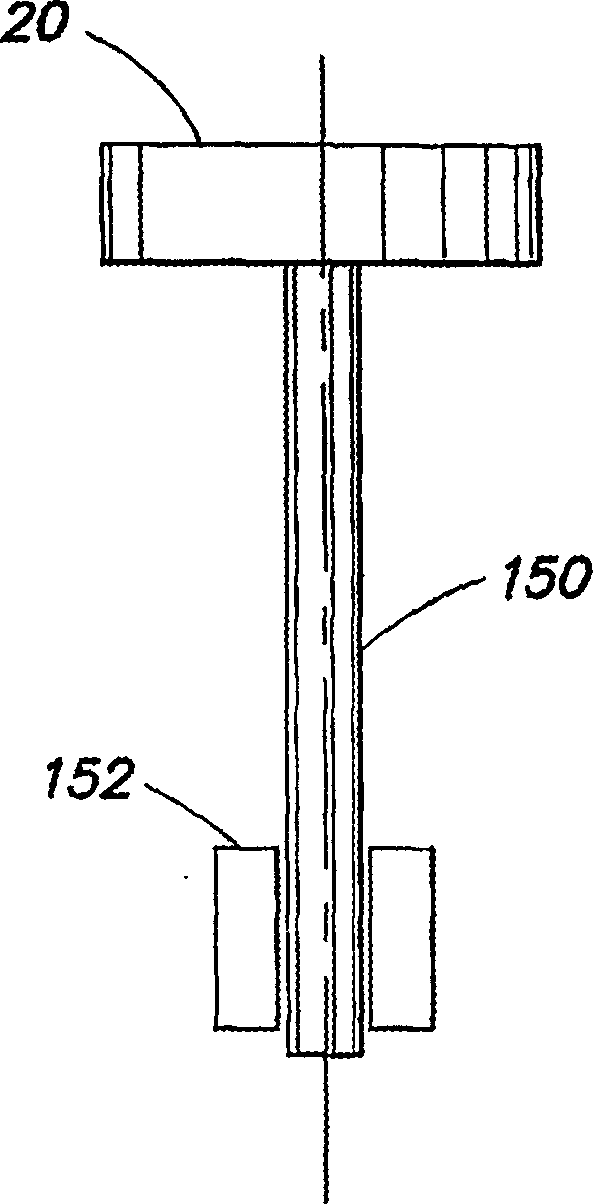

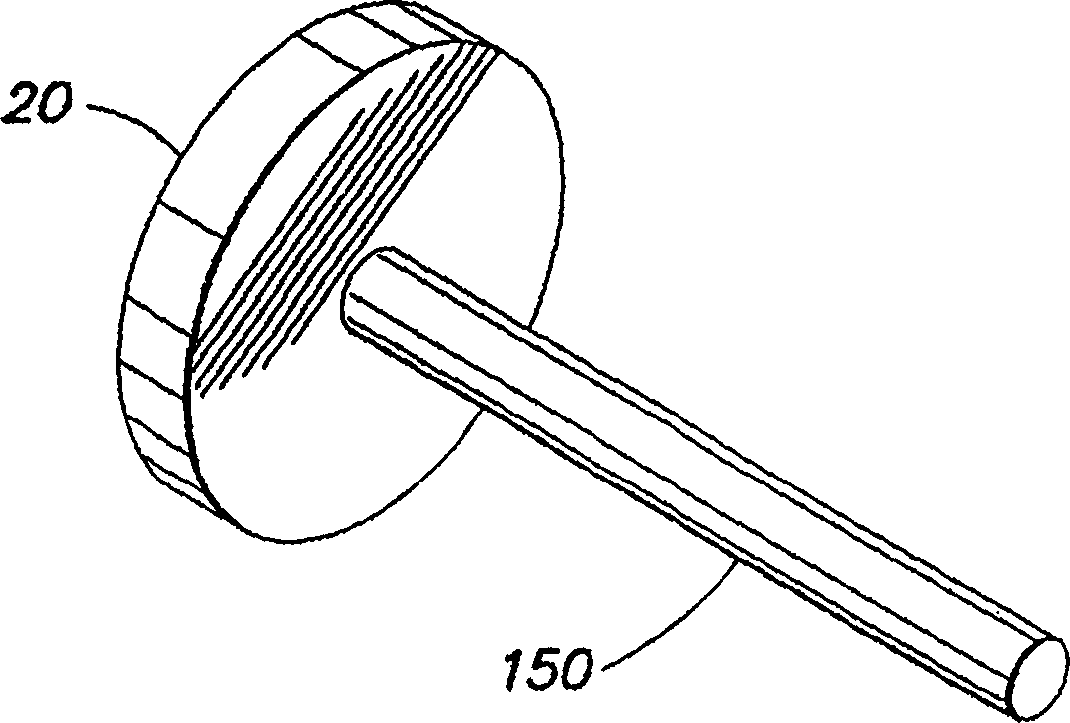

[0025] figure 1 An indirect heated ion source according to one embodiment of the invention is shown. An arc chamber housing 10 with an extraction opening 12 defines an arc chamber 14 . A cathode 20 and a reflective electrode 22 are mounted within the arc chamber 14 . The reflective electrode 22 is electrically insulating. A cathode isolation device 24 electrically and thermally insulates the cathode 20 from the arc chamber housing 10 . Cathode 20 and insulating device 24 are spaced apart to prevent heat conduction.

[0026] Cathode 20 is heated by a filament 30 mounted outside arc chamber 14 in close proximity to cathode 20 .

[0027] Ionized gas is introduced into the arc chamber 12 from the gas source 32 through a gas inlet 34 . In another configuration not shown, the arc chamber 14 may be combined with a vaporizer capable of vaporizing a substance ionizable within the arc chamber.

[0028] An arc power supply 50 includes a positive terminal coupled to the arc chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com