Molded resin gear, moded resin rotaor and molded article

A technology of injection molding and resin, which is applied to gears, components with teeth, belts/chains/gears, etc. It can solve the problems of negative impact on tooth profile accuracy, impact on gear strength, easy eccentricity of shaft hole 55, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

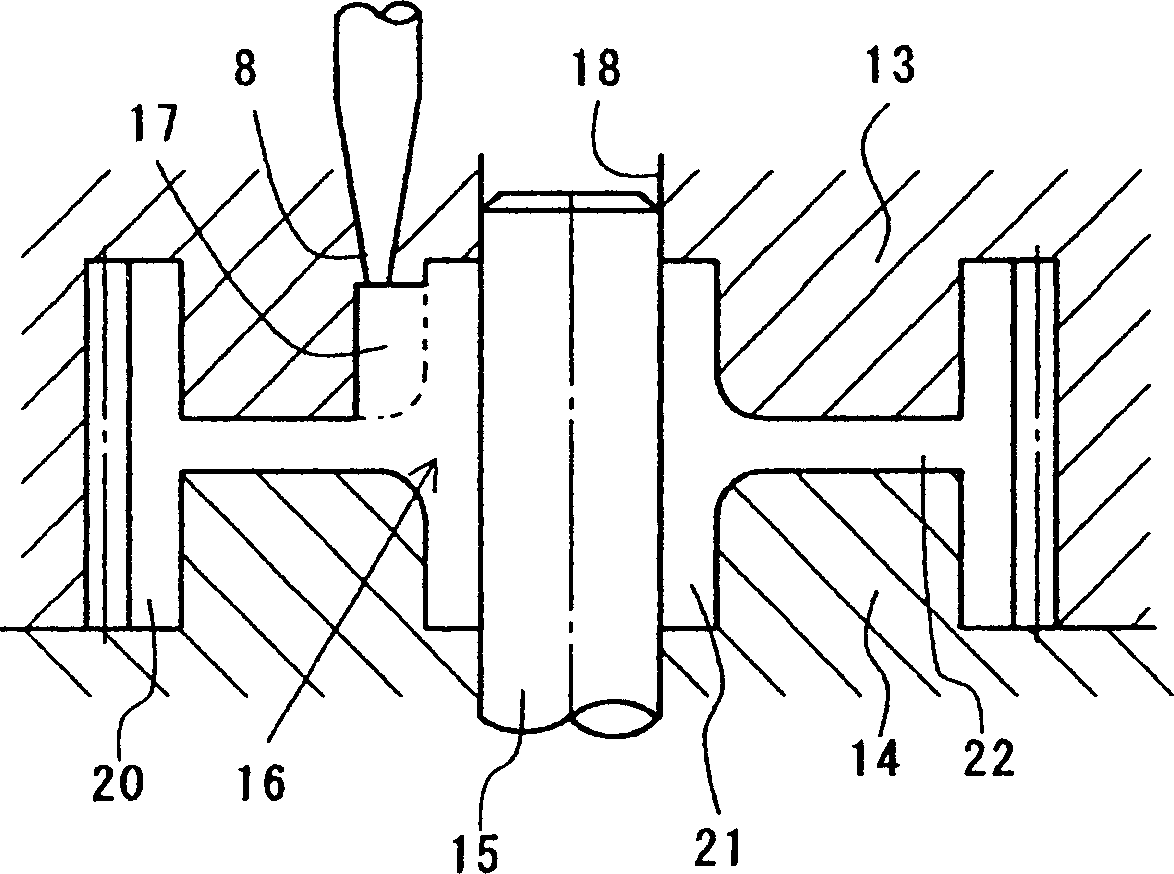

[0047] In the following, reference will be made to the accompanying drawings, especially Figure 1 to Figure 16 , the preferred embodiments of the present invention are described in detail.

[0048] first preferred embodiment

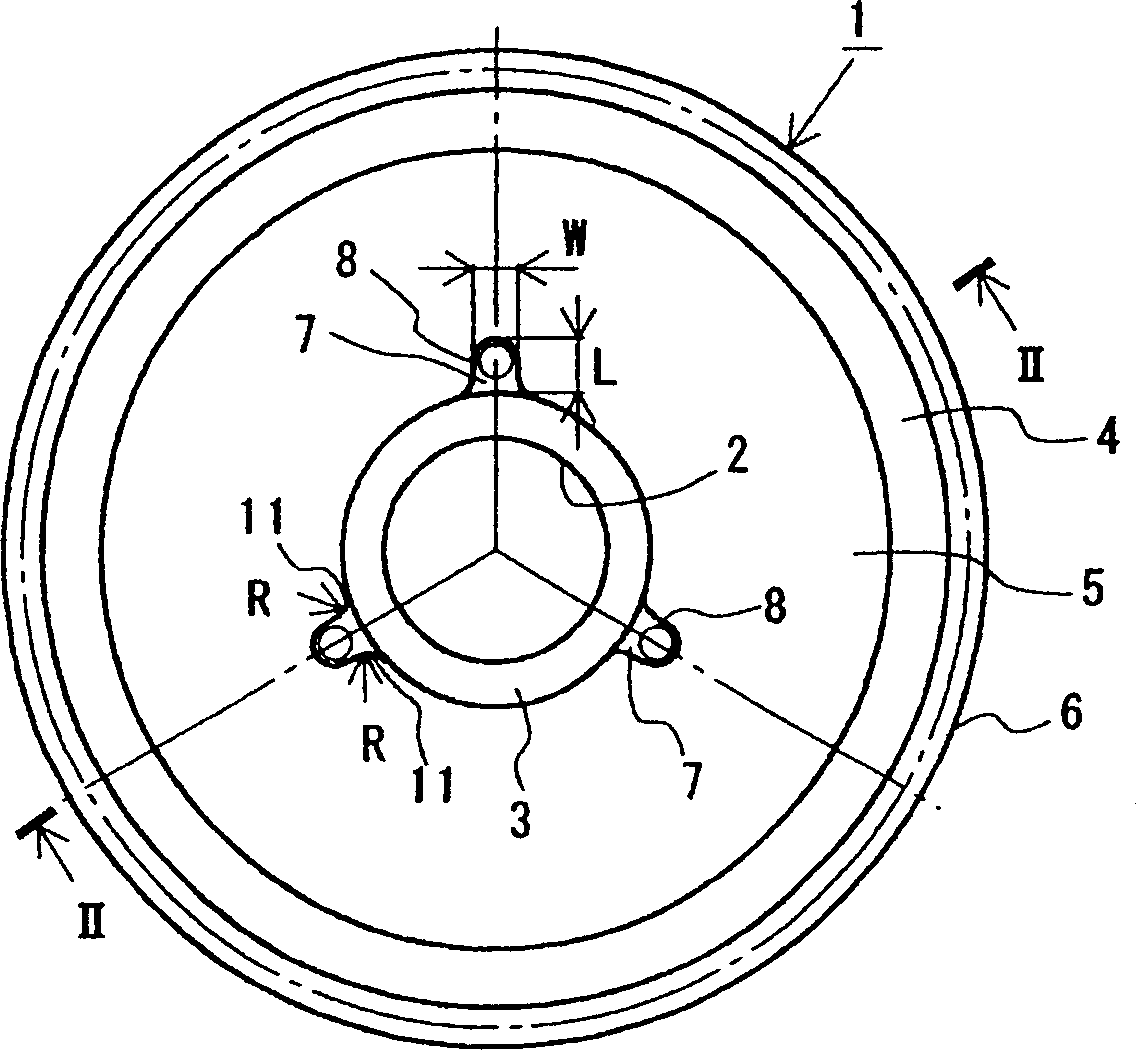

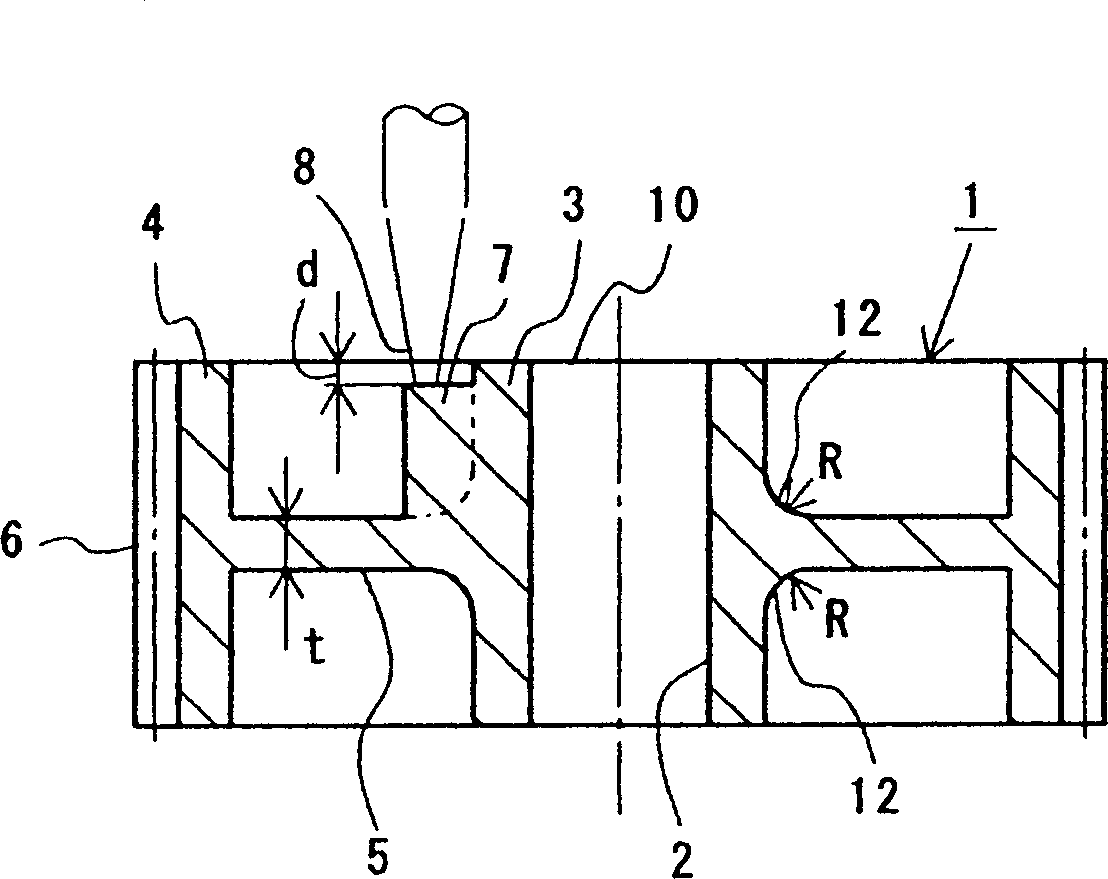

[0049] figure 1 and figure 2 A first preferred embodiment of the injection molded resin gear 1 according to the present invention is shown, figure 1 is a side view of the injection molded resin gear 1, while figure 2 for along figure 1 A sectional view taken along the line II-II.

[0050] The injection-molded resin gear 1 shown in these drawings is made by pouring molten resin material such as polyacetal, polyamide, polyphenylene sulfide, or polybutylene terephthalate from a pinpoint type gate. Formed in the mold cavity.

[0051] The injection molded resin gear 1 includes: a substantially cylindrical hub (inner cylindrical portion) 3 having a shaft hole 2; a substantially cylindrical rim (outer cylindrical portion) 4 concentric with the hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com