Molded lump and production method therefor

A manufacturing method and block technology, which is applied in the field of block, can solve the problems of short retention time and deterioration of combustion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

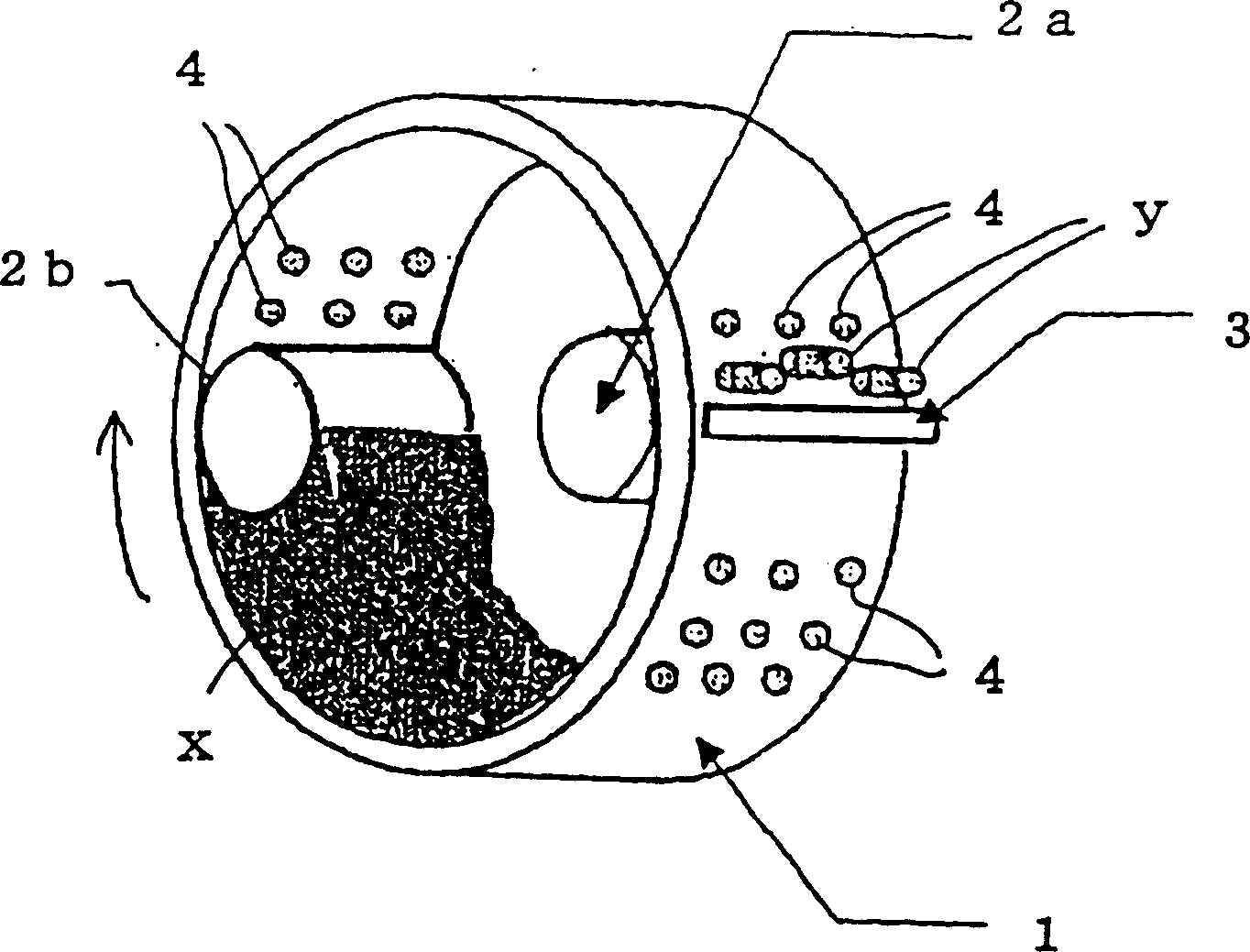

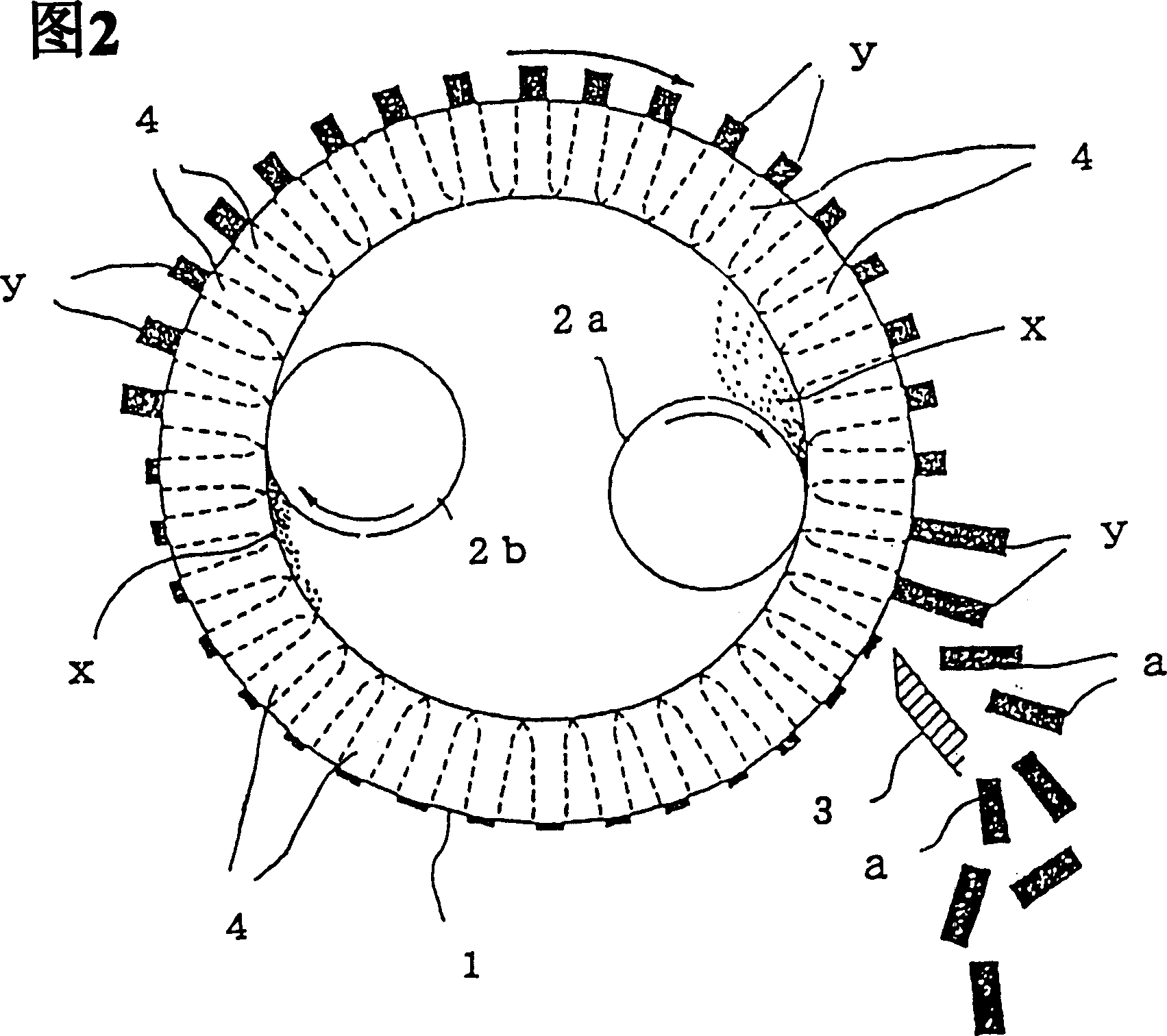

[0141] use figure 1 With the granulation device shown in Fig. 2, waste plastics were pretreated with examples of the present invention and comparative examples (existing methods).

[0142] In the present embodiment, use die opening inner diameter: 840mm, die opening width: 240mm, die opening thickness (die hole length): 60mm, turning roller roll diameter: 405mm, die hole diameter: 6mm, number of die holes: 10,000 The granulation device feeds at a total speed of 1.0-1.5t / h of solid plastic (A) and flake plastic (B) (flaky plastic). The sheet-like plastic (B) is 32% by weight of polyethylene, 31% by weight of polypropylene, 22% by weight of polystyrene, and 15% by weight of others (such as paper). The solid plastic (A) is 37% by weight of polyethylene, 34% by weight of polypropylene, 22% by weight of polystyrene, and 7% by weight of others (paper, etc.).

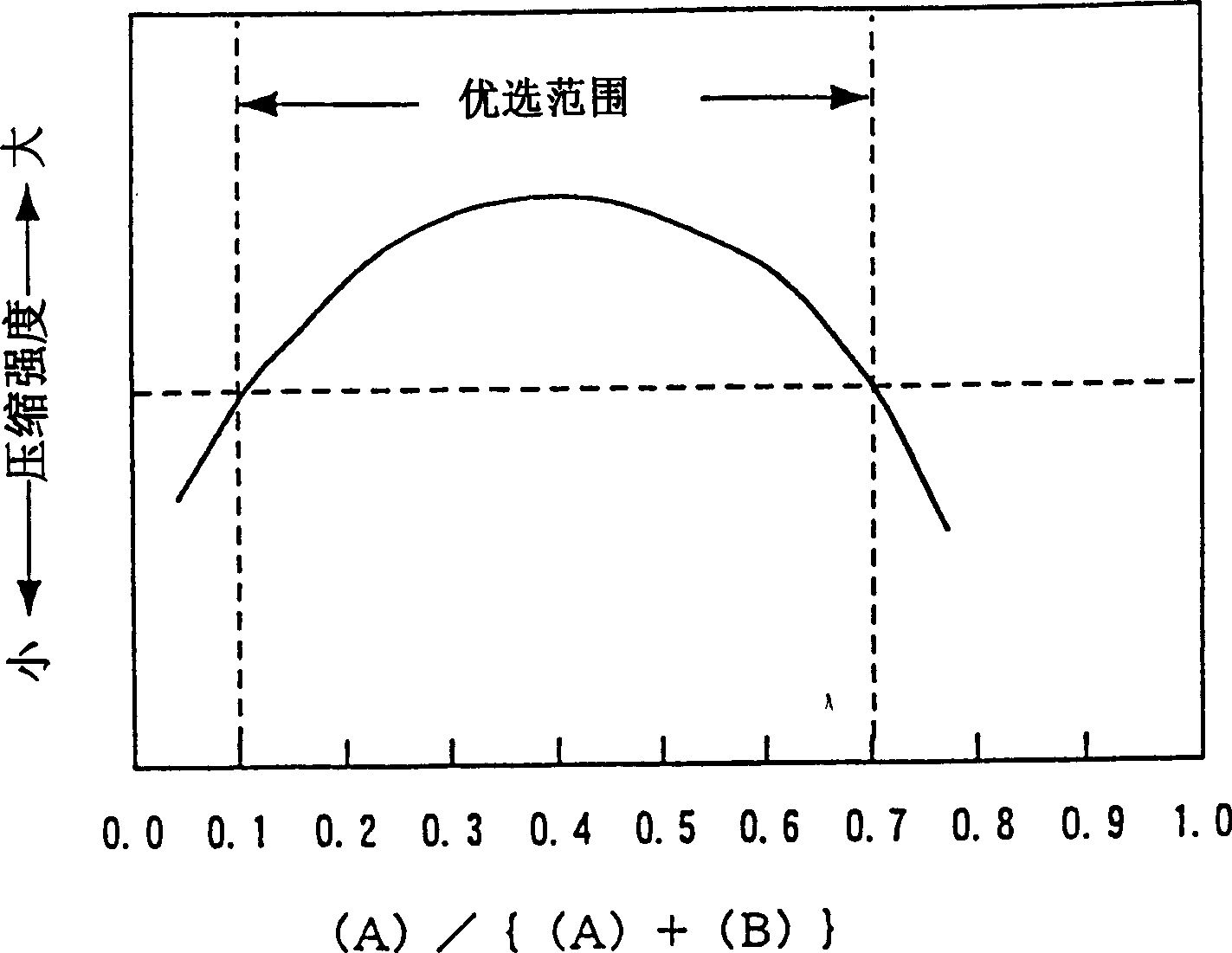

[0143] Table 1 shows the results of the examples of the present invention and the comparative examples. The strength, pro...

Embodiment 2

[0211] Except using the following block of the present invention manufactured by a porous extrusion molding machine, it is the same as in Example 1, and the existing block is passed through a pneumatic feeding device, and is sprayed from the blast furnace tuyere in operation. , and investigated malfunctions such as blockages in the equipment. That is to say, use a ring-shaped die-type granulator with an effective die thickness T: 70mm and a die diameter d: φ6 mm to make lumps from raw materials with a prepared particle size D: 10-15 mm. The outlet temperature of the granulator was 110°C. At this time, the average strength index of the block is 600, and the size of the block is φ6×10mm.

[0212] As a result, the cakes within the scope of the present invention showed a high percent burnup of over 90%. On the contrary, the lumps outside the range of this invention have a combustion rate of 50 to 88% and clogging due to their strength or particle diameter outside the range of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com