Holding/sealing material for use in catalytic converter for clarifying gaseous emission

A technology for purifying exhaust gas and sealing materials, applied in catalyst protection, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as the deterioration of the working environment, and achieve the effect of a good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

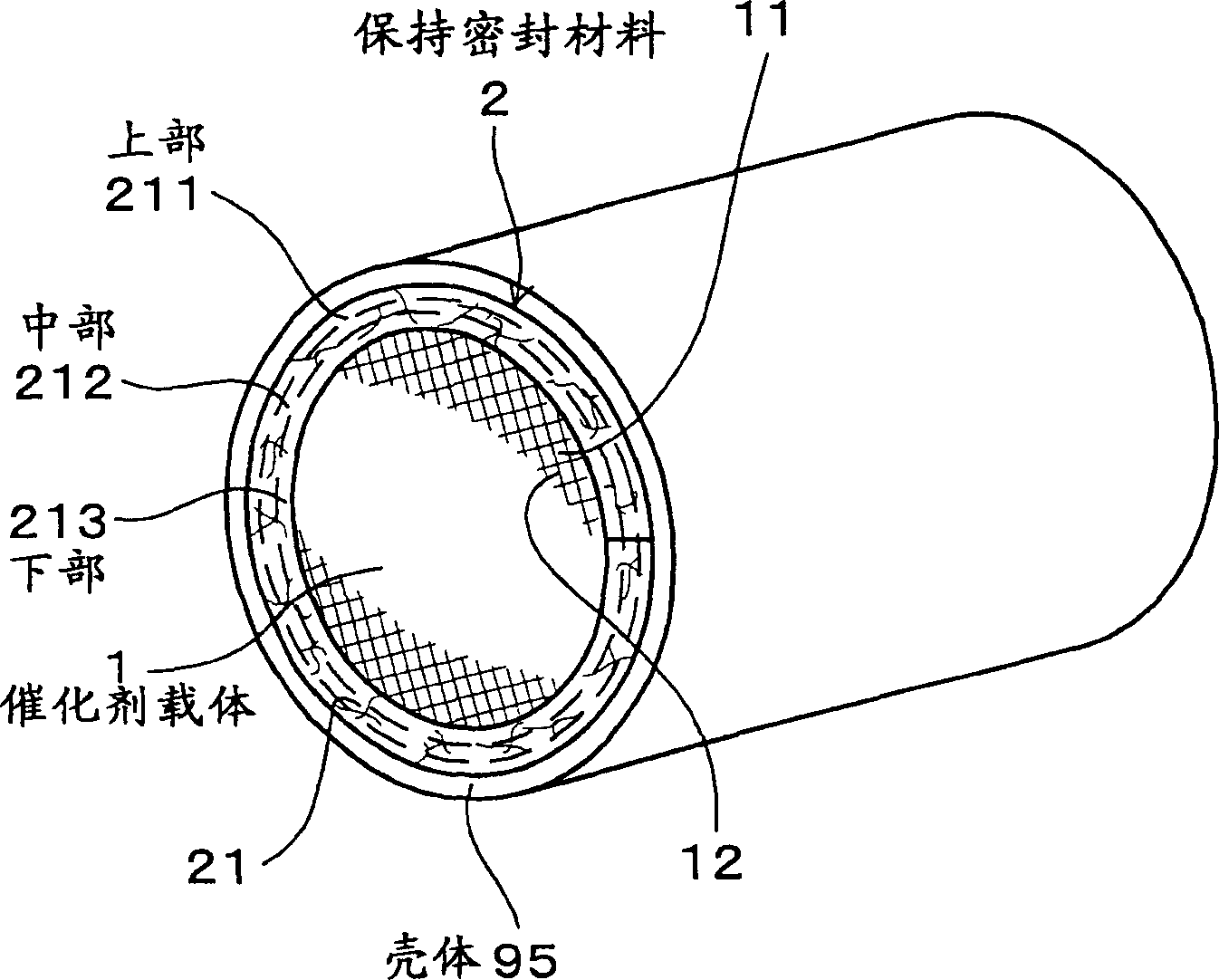

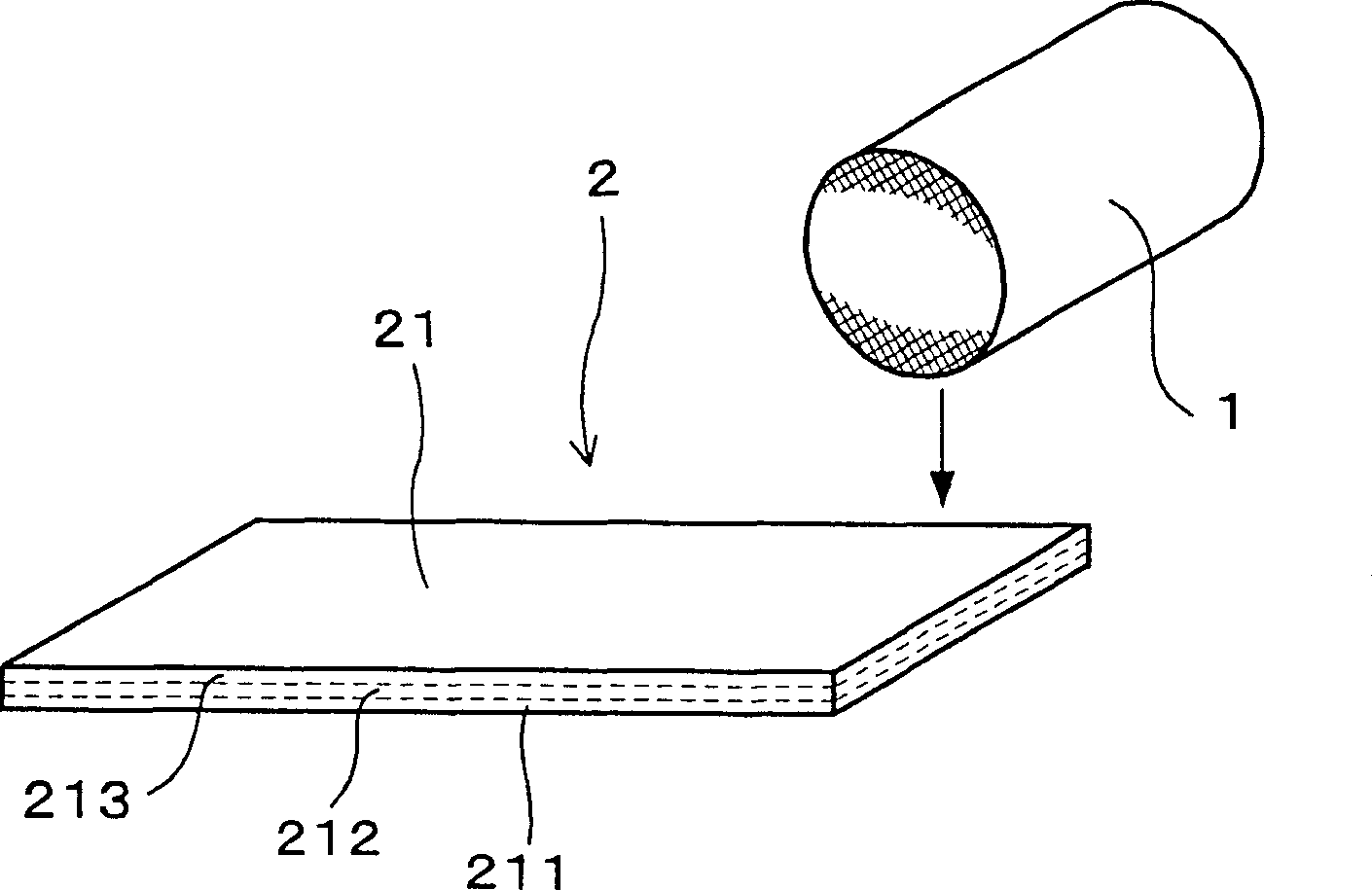

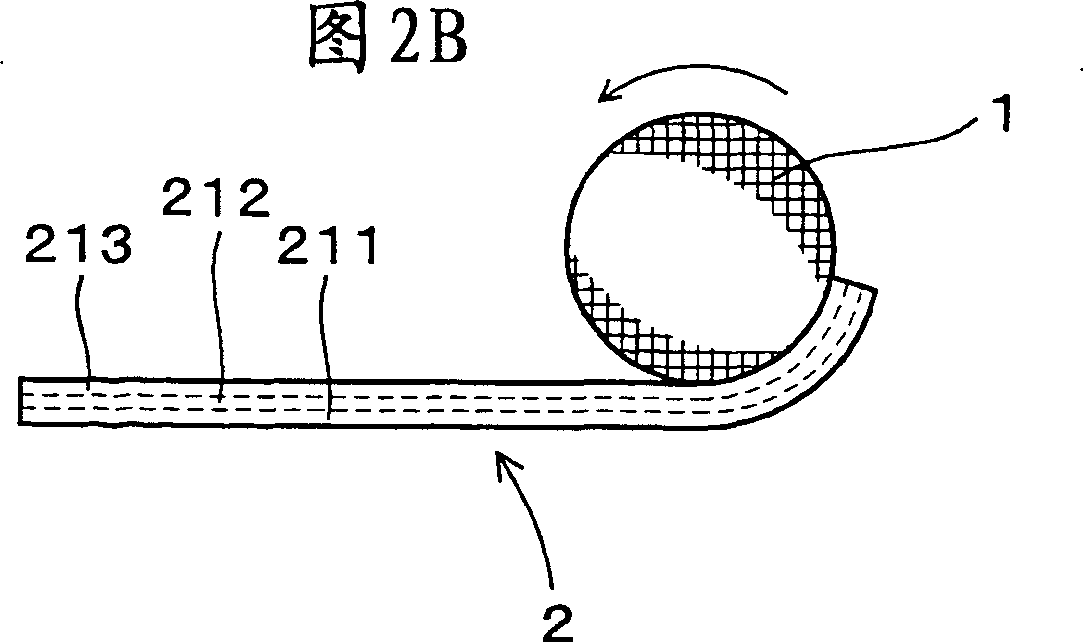

[0032] use Figure 1 to Figure 5 The holding sealing material of the catalytic converter for purifying exhaust gas in the embodiment of the present invention will be described.

[0033] Such as figure 1 As shown, the holding sealing material 2 in this embodiment is used by being placed between the catalyst carrier 1 and the case 95 covering the outer side of the exhaust gas-purifying catalytic converter 10 . In addition, the binder that will be made of 0.5~20% by weight of organic binder or inorganic binder is added to the cushion material 21 (referring to Fig. 2 (A), Figure 2(B)) to form a holding sealing material 2, and at the same time, adjust the packing density after assembly to 0.1 ~ 0.6g / cm 3 In the range.

[0034] And, in the above-mentioned holding sealing material 2: the upper part 211, the middle part 212, and the lower part 213 are divided into three equal parts along the thickness direction of the above-mentioned cushion-shaped material 21 to measure the solid...

Embodiment 2

[0053] In this example, the following drop test was performed in order to ensure that the inorganic fibers contained in the mat-like material 21 were not easily scattered into the air.

[0054] That is, in this drop test, cushion-like materials 21 (invention products 1 and 2) to which different binders were added and cushion-like materials 21 (comparative products) to which no binder was added were used. Fall from height 10 times. Afterwards, by detecting the weight loss rate of the mat-like material 21 after falling, the scattering of the inorganic fibers in the mat-like material 21 into the air can be measured.

[0055] (Invention product 1)

[0056] In the free state before assembly, with a bulk density of 0.05g / cm 3 1. In the cushion-like material 21 made of crystalline aluminum fibers with a thickness of 25 mm, latex was added as a binder to account for 1% (percentage by weight) of the cushion-like material 21 as a whole. In addition, the distribution rate of the adhes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com