BL diaphragm assembling equipment

A technology for assembling equipment and diaphragms, which is used in metal processing equipment, metal processing, manufacturing tools, etc., to reduce equipment costs, improve product yield, and reduce inclusions of foreign matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

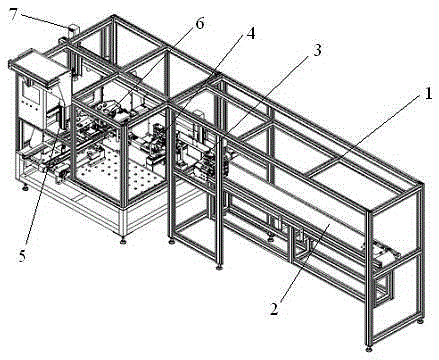

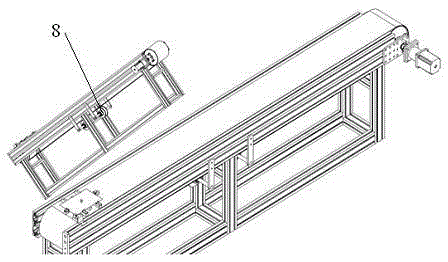

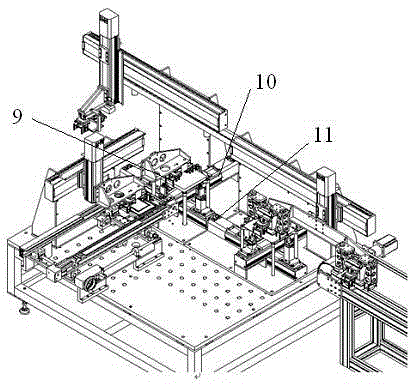

[0027] refer to Figure 1 to Figure 4 as shown, figure 1 It is an overall assembly structure diagram of a BL diaphragm assembly equipment of the present invention, which includes an equipment housing 1, a diaphragm conveying line 2, a diaphragm initial positioning and transplanting mechanism 3, a diaphragm second high-precision positioning 4, OPENBL anti- Electrostatic transport mechanism 5, diaphragm and heart assembly mechanism of OPENBL 6, finished product loading mechanism 7;

[0028] The top of the equipment shell 1 is covered with FFU. FFU is a high-efficiency air filter with a large load, which can realize the exchange of constant airflow and variable airflow, and can ensure that the BL diaphragm assembly equipment is assembled below 100 levels.

[0029] figure 1 The four diaphragms shown are dedusted by the upstream de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com