Back light source and front light source and liquid crystal display device

A technology of a liquid crystal display device and a liquid crystal display unit, which is applied in the field of liquid crystal display devices with the backlight or front light source, can solve the problems of low luminance, large power consumption, and short light-emitting life of EL elements, and achieve cost reduction, less noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

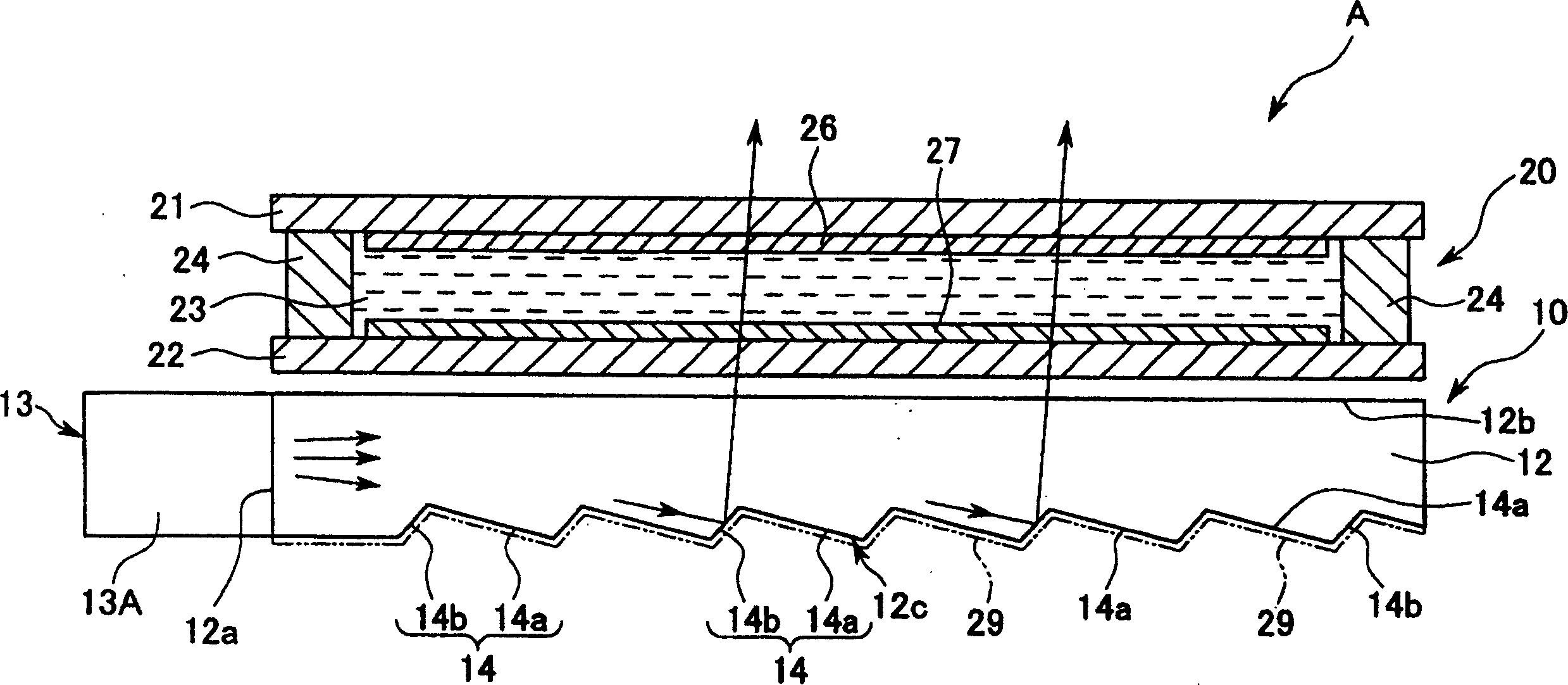

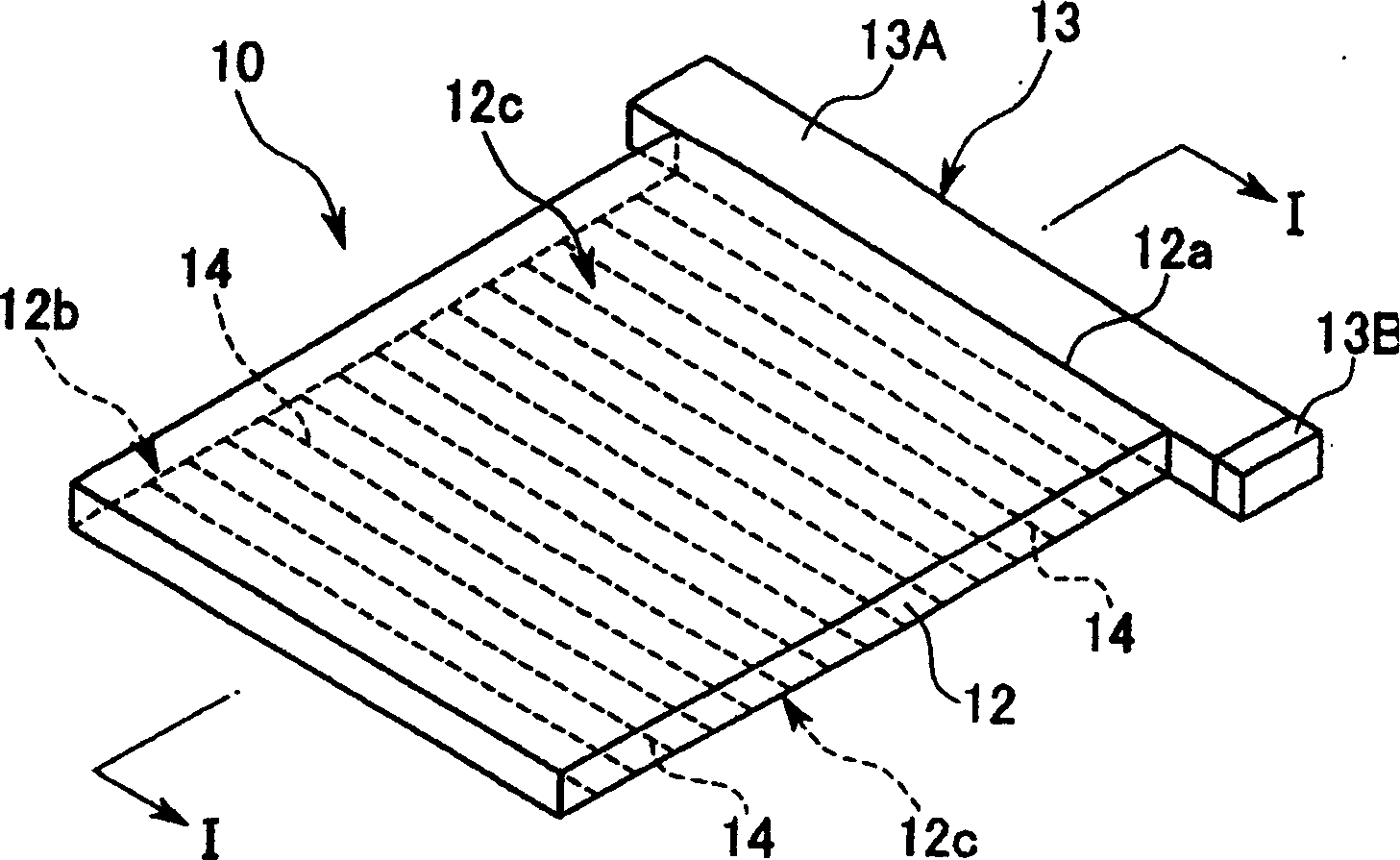

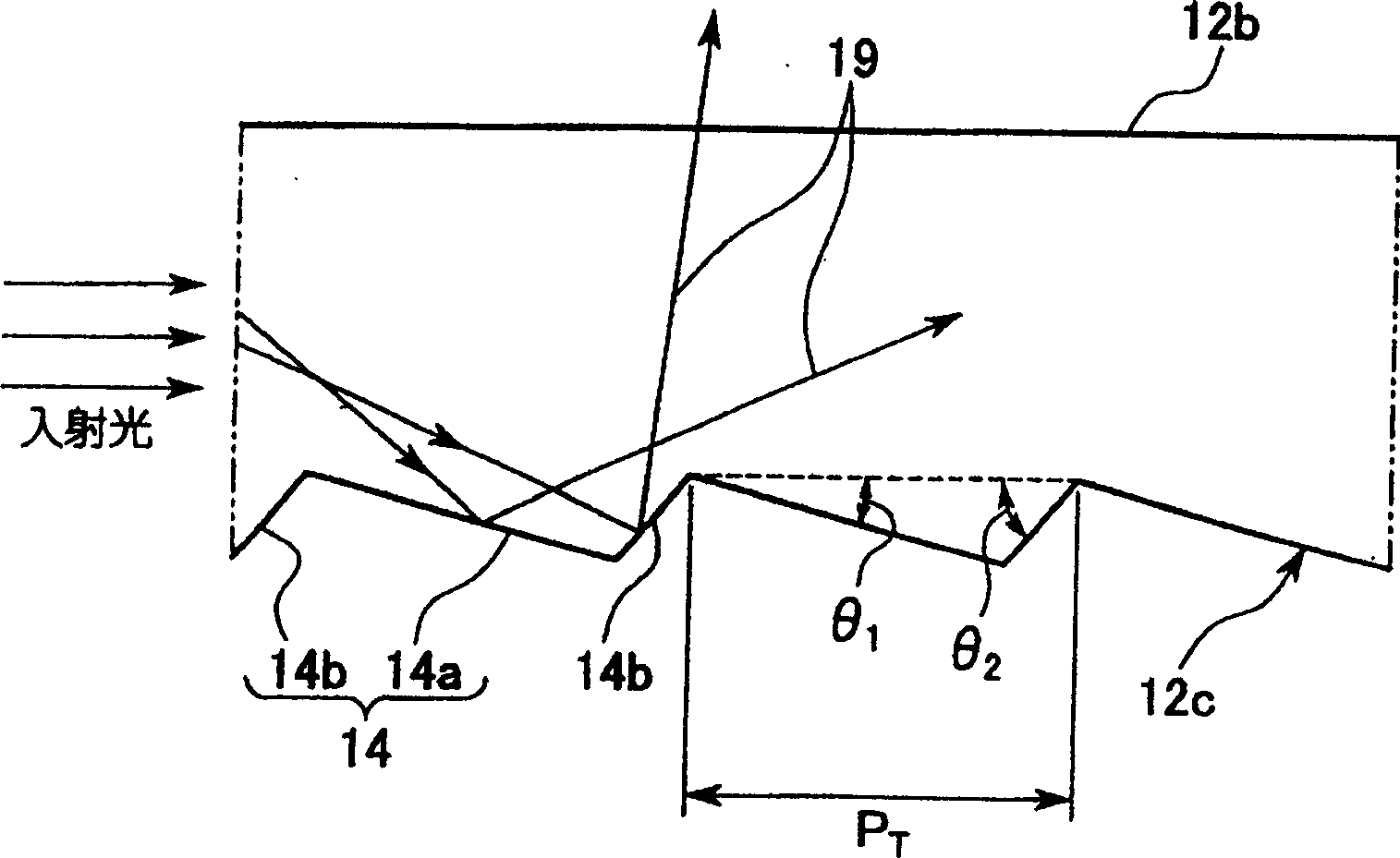

[0069] figure 1 A cross-sectional view showing a transmissive or semi-transmissive liquid crystal display device including a backlight (planar light-emitting device) according to the first embodiment of the present invention, figure 2 represents a perspective view of the backlight, image 3 A partially enlarged side view of the backlight is shown. figure 1 The cross-sectional direction is along the figure 2 The direction of the I-I line.

[0070] The liquid crystal display device A of this embodiment is roughly composed of a liquid crystal display unit 20 and a backlight 10 arranged on the back side of the liquid crystal display unit 20 to illuminate the liquid crystal display unit 20 from the back side.

[0071] The liquid crystal display unit 20 is a transmissive or semi-transmissive type in this embodiment, and is generally configured as a transparent first substrate 21 made of glass sandwiching a liquid crystal layer 23 and a transparent second substrate 22 with an ...

no. 2 Embodiment

[0104] Figure 10 A partial perspective view showing the configuration of a front light source (surface light emitting device) according to a second embodiment of the present invention. in addition, Figure 11 means from Figure 10 The shown front light source 50 is a partial perspective view of a state where a cover member 58 described later is removed. The front light source 50 shown in these figures includes a flat plate-shaped light guide plate 52 made of a transparent resin material, and a side end portion (one end on the short side of the rectangular light guide plate 52) disposed on the side end surface 52a side of the light guide plate 52. part), the rod-shaped light guide (light guide) 53 on the rod-shaped light guide 53, the light-emitting elements (light sources) 55, 55 arranged on both ends of the rod-shaped light guide 53 in the longitudinal direction, and the light-emitting elements covering the above-mentioned rod-shaped light guide 53 The element 55 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com