Rotor assembly for electric motor and electric motor with internal rotor

A technology of electric motors and inner rotors, which is applied in the field of brushless motors and DC motors, can solve the problems of unsuitable and not allowing direct mechanical connection of loads, etc., and achieve the best effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

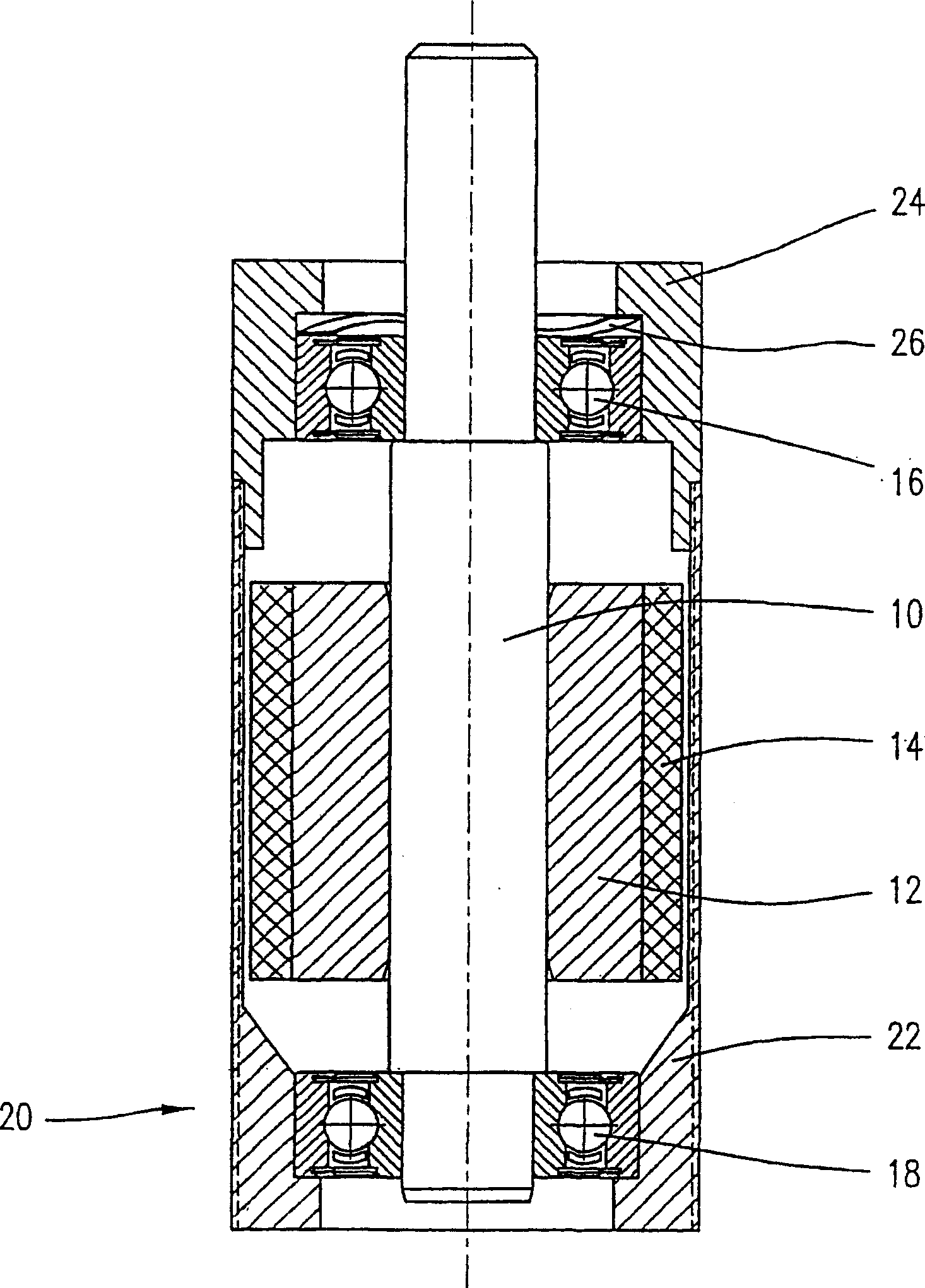

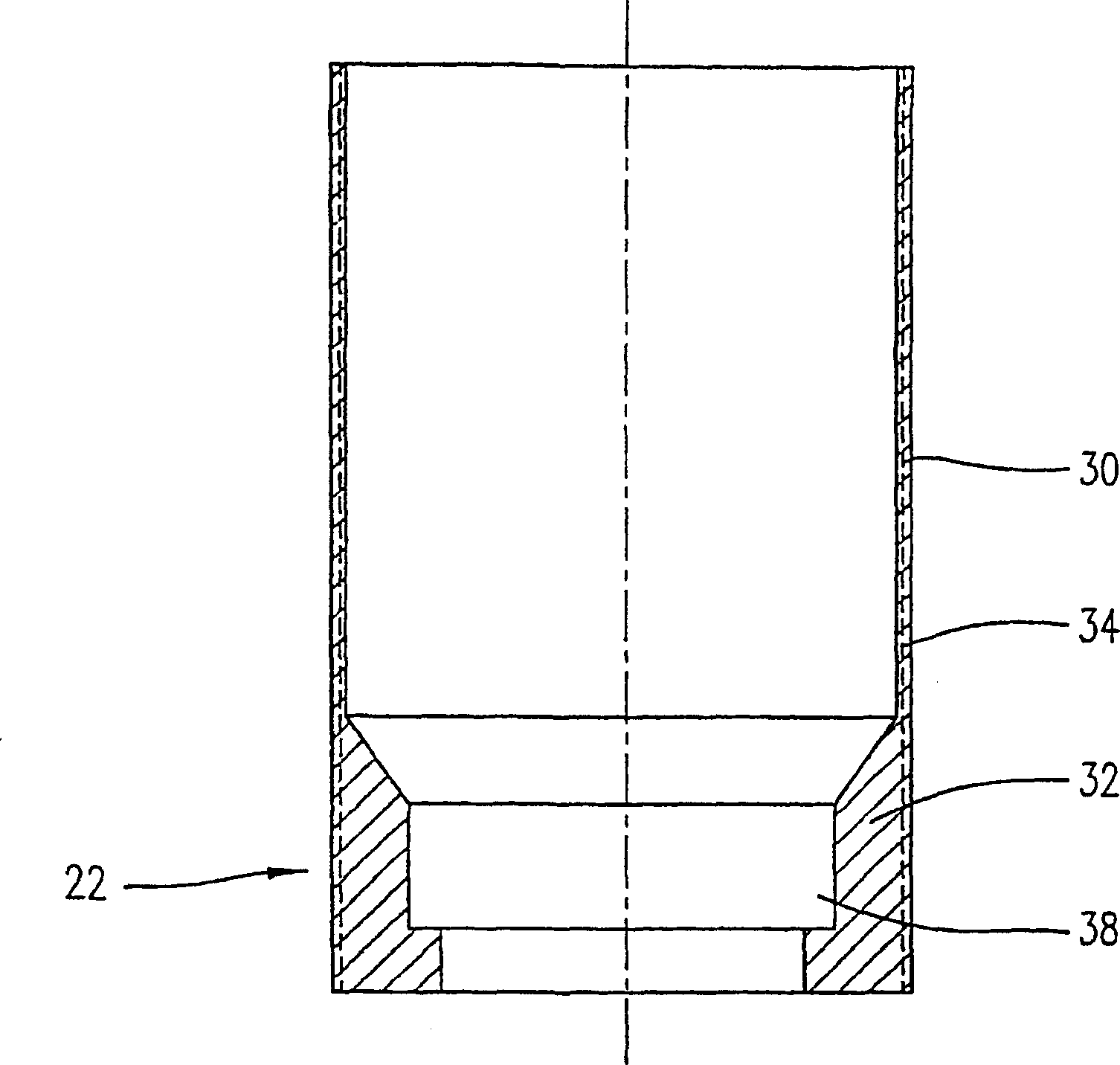

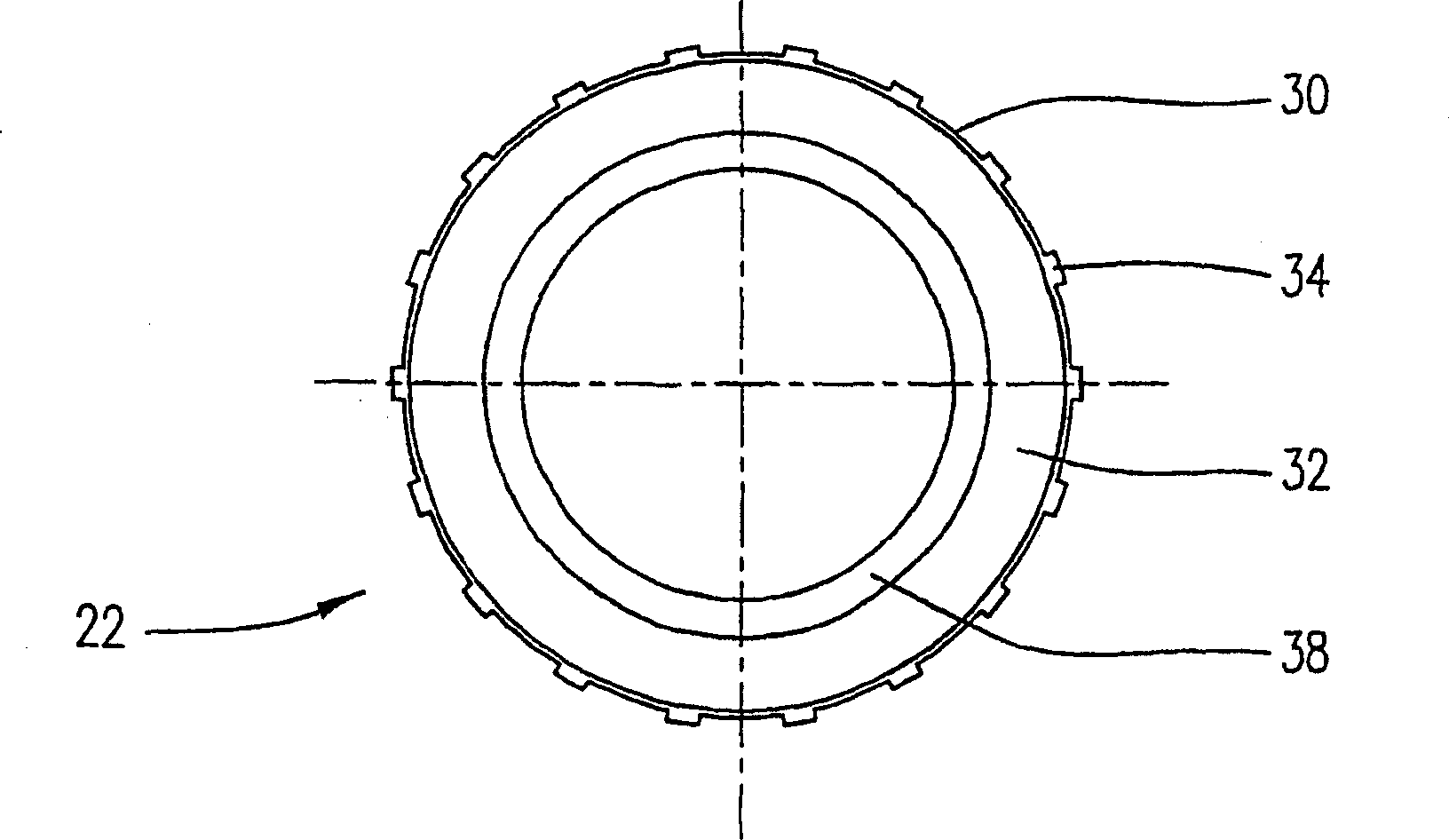

[0035] figure 1 A cross-sectional view of a preferred embodiment of a rotor assembly according to the invention is shown. The rotor assembly according to the invention comprises a rotor shaft 10 carrying a yoke ring 12 made of a soft magnetic material such as iron. Attached to the yoke ring 12 is a preferably annular permanent magnet 14 . The shaft 10 is rotatably journaled in bearings 16 , 18 , wherein the bearings 16 , 18 can be formed as anti-friction or friction bearings and in particular as roller bearings. Here the rotor, made of rotor shaft 10, yoke ring 12 and permanent magnets 14, is sealed in a sleeve 20 comprising a sealing section 22 and a flange section 24, which will be referred to Figures 2 to 5 Explain in detail.

[0036] The bearings 16, 18 can be preassembled on the rotor shaft 10 and placed in the end faces of the sleeve sections 22, 24, pressed into them and / or glued to them, or fixed in another suitable way . In the illustrated embodiment, an annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com